Repairing device and repairing method of urban pipeline gallery leakage expansion joint

A technology of expansion joints and pipe galleries, applied in protection devices, water conservancy projects, artificial islands, etc., can solve problems such as inability to effectively repair cracks and long-term use, and achieve improved reliability and stability and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

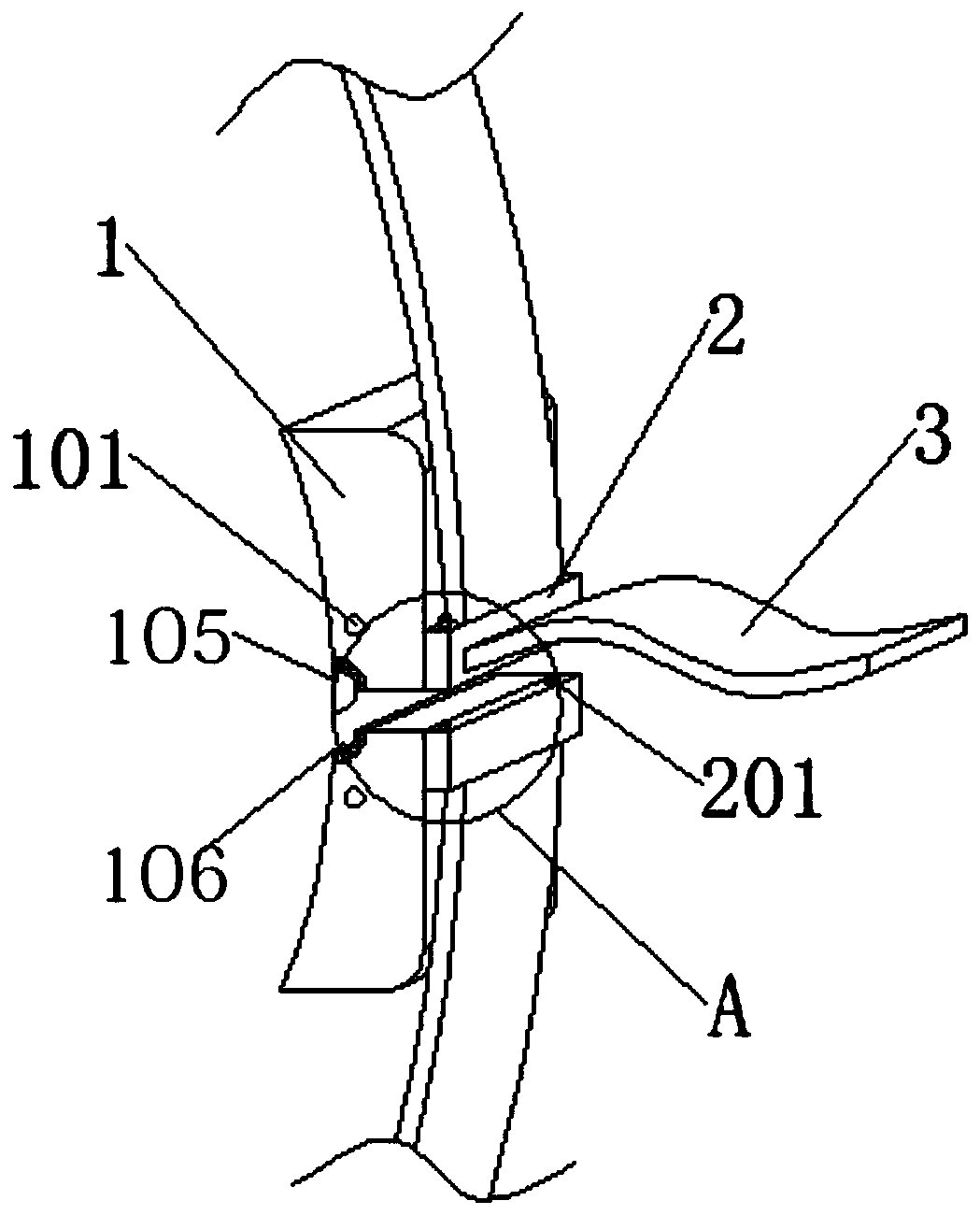

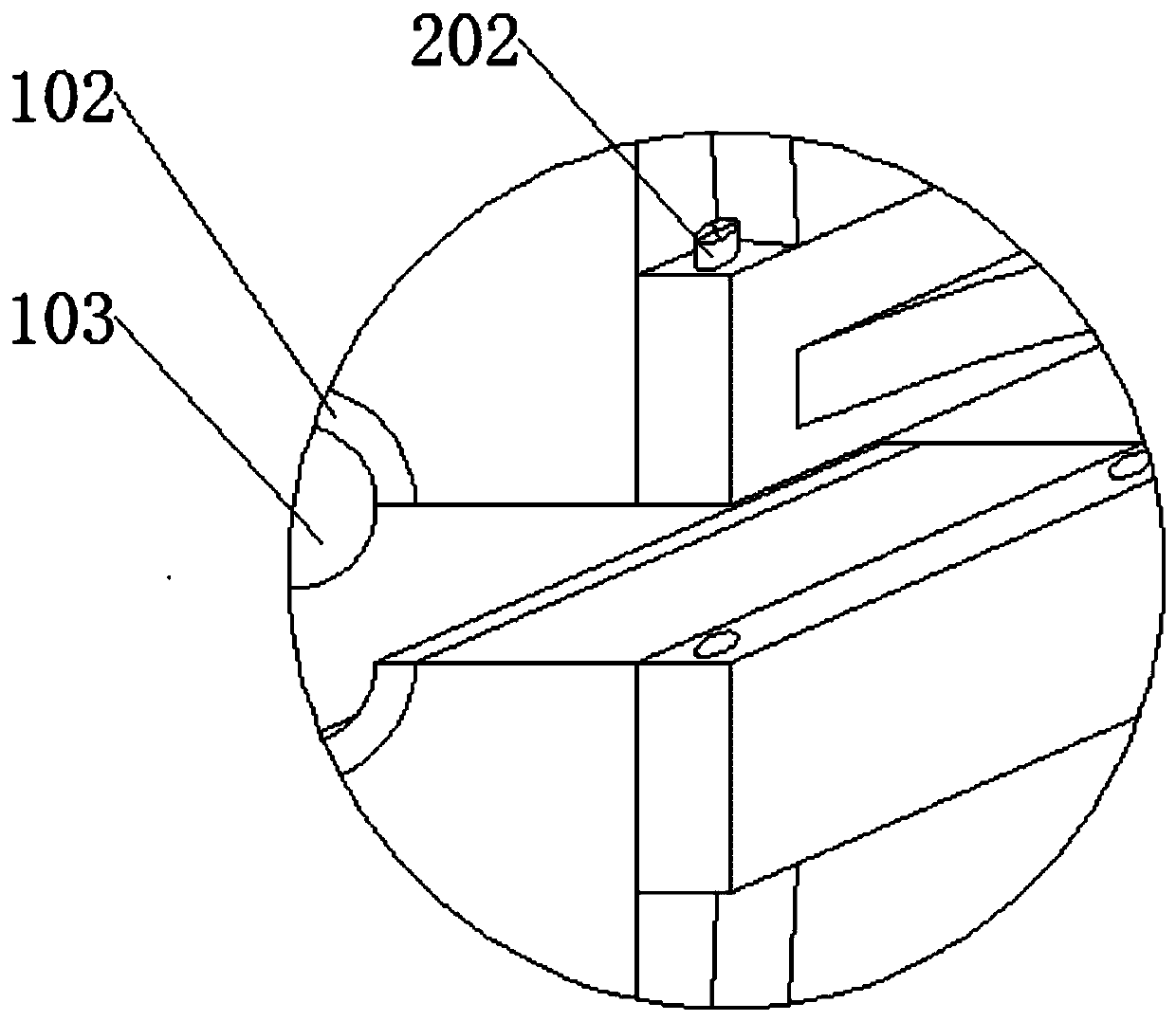

[0044] In a typical embodiment of the present invention, such as figure 1 and figure 2 As shown, a device for repairing expansion joints of urban pipe gallery leakage, including a strap, which can be arranged around the pipe; , the strap can be pulled relative to the movable end; the fixer 1, the fixer 1 is connected with the strap fixing part, the fixer 1 is provided with a groove for setting the bonding material in the groove, so as to apply the bonding material Overlay on the place where the pipeline needs to be repaired. Further, the fixer 1 includes a first end connected to the fixed end and a second end connected to the movable end, so that when the movable end is close to the fixed end, the first end and the second end also close to each other.

[0045] Wherein, the groove includes a first card slot 105 provided at the first end and a second card slot 106 provided at the second end. When the second end is in use, the fixed end of the strap holder 2 is below. The fir...

Embodiment 2

[0053] A method for repairing leakage and expansion joints of urban utility corridors, using the device for repairing leakage and expansion joints of urban utility corridors described in Embodiment 1, comprising the following contents:

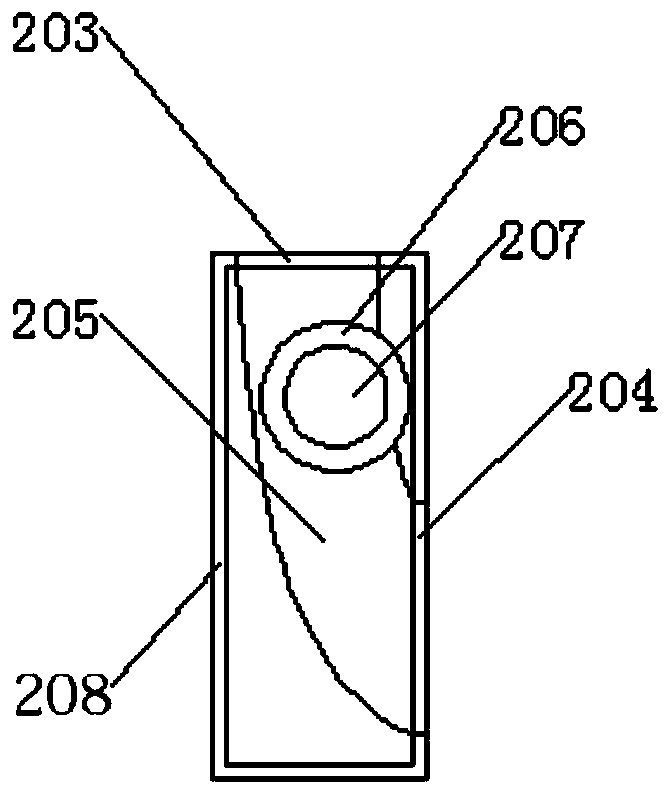

[0054] Apply the glue evenly on the outside of the water storage tank 104 of the fixer 1, then fix the fixer 1 with screw holes 201 on the lower end of the expansion joint of the pipeline, and then fix the fixer 1 with the fixing screws 202 on the pipe The upper end of the expansion joint, at this moment, the staff just can pass the strap 3 into the strap inlet 203 on the strap holder 2, and extend from the strap outlet 204, then, the staff passes the one-way wheel 207 to Adjust the tension of the strap 3 so that the strap 3 is at 34-69σb, the staff will place the BB glue stick in the recess, and start the heating plate 102 through the switch key 101 to heat for 10-30min, and then the staff will turn off the heating plate 102 Then adjust the b...

Embodiment 3

[0056] A method for repairing leakage and expansion joints of urban utility corridors, using the device for repairing leakage and expansion joints of urban utility corridors described in Embodiment 1, comprising the following contents:

[0057] Apply the glue evenly on the outside of the water storage tank 104 of the fixer 1, then fix the fixer 1 with screw holes 201 on the lower end of the expansion joint of the pipeline, and then fix the fixer 1 with the fixing screws 202 on the pipe The upper end of the expansion joint plays the role of initially fixing the fixed end and the movable end of the strap through the glue. At this time, the staff can pass the strap 3 into the strap inlet 203 on the strap holder 2, and Extending from the strap outlet 204, then the staff adjusts the tension of the strap 3 through the one-way wheel 207, so that the strap 3 is at 53σb, the worker places the BB glue stick in the heating plate 102, and passes the switch Key 101 starts the heating plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com