Multi-connecting-rod type tire clamping device carried on AGV and operation method of multi-connecting-rod type tire clamping device

A multi-link, multi-link technology, applied in the field of intelligent parking robots, can solve problems such as high cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

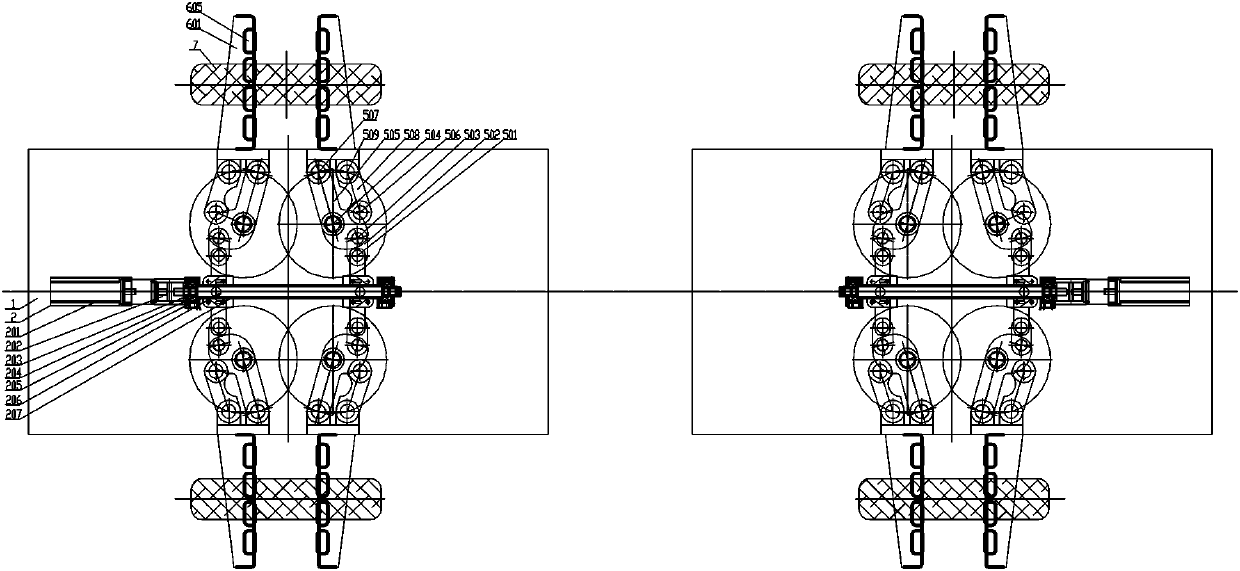

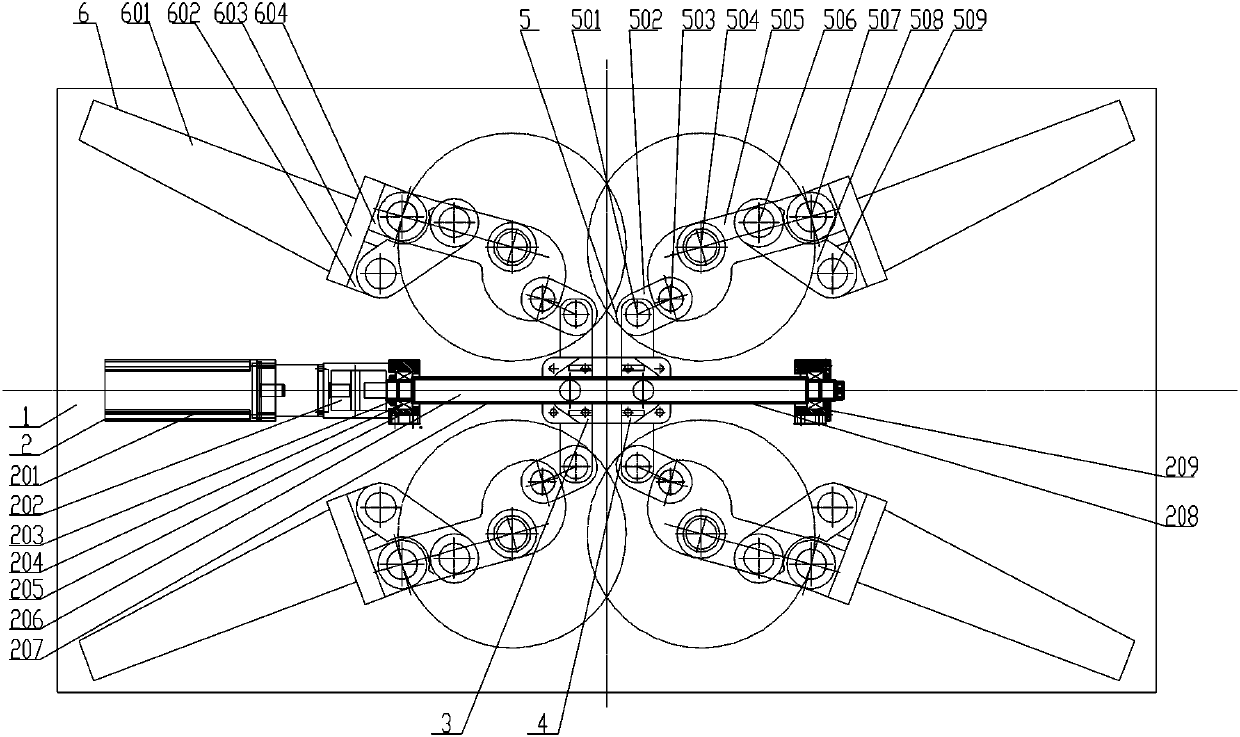

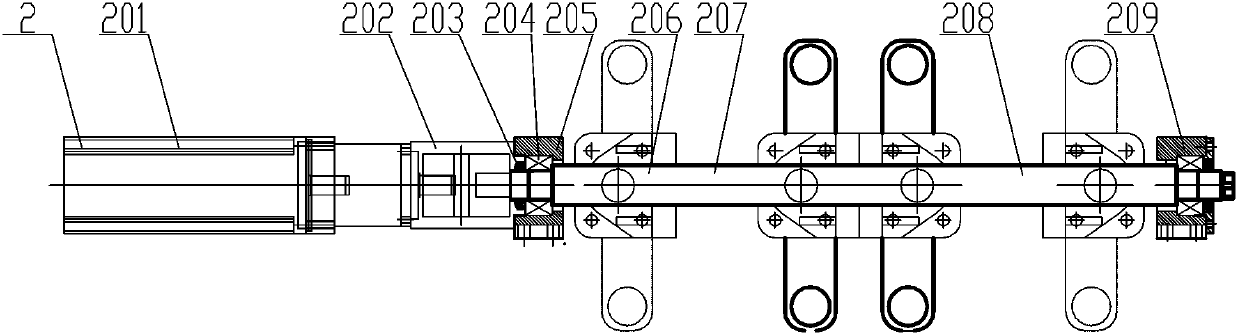

[0046] like Figure 1-12 As shown, the multi-link tire clamping device mounted on the AGV trolley includes two sets of symmetrically arranged open-close tire clamp mechanisms for synchronous clamping and lifting of the four wheels of the car; each set of open-close tire clamps Mechanisms all include a ball screw mechanism 2 for providing driving force, and the ball screw mechanism 2 is fitted with a first nut sleeve structure 3 and a second nut sleeve structure 4 through screw transmission; the first nut sleeve structure 3 And the two ends of the second nut sleeve structure 4 are respectively hinged with a multi-linkage mechanism 5 for realizing the opening and closing action, and each execution end of the multi-linkage mechanism 5 is connected with a multi-linkage mechanism for clamping with the outer wall of the automobile tire. The clamping arm structure 6. By adopting the multi-link tire clamping device with the above structure, it can be used in the intelligent garage, t...

Embodiment 2

[0056] The operation method of any one of the multi-link tire clamping devices mounted on the AGV trolley is characterized in that it comprises the following steps:

[0057] Step 1, start the ball screw mechanism 2, drive the first nut sleeve structure 3 and the second nut sleeve structure 4 on the corresponding side through the ball screw mechanism 2, and then drive the first nut sleeve structure 3 and the second nut sleeve structure 4 The respective multi-link mechanism 5 drives the corresponding clamping arm structure 6 to open through the multi-link mechanism 5, so that it is close to the central axis of the AGV trolley and ensures that it can pass through the bottom of the car smoothly;

[0058] Step 2, the entire contracted tire clamping device is carried by the AGV trolley and moved to the bottom of the car, and the respective symmetrical centerlines of the four pairs of clamping arm structures 6 are roughly aligned with the axis line of the vehicle wheel to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com