Height adjusting method for coal checking system

A technology of height adjustment and panning, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of unstable measurement accuracy and high randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Such as figure 1 Shown:

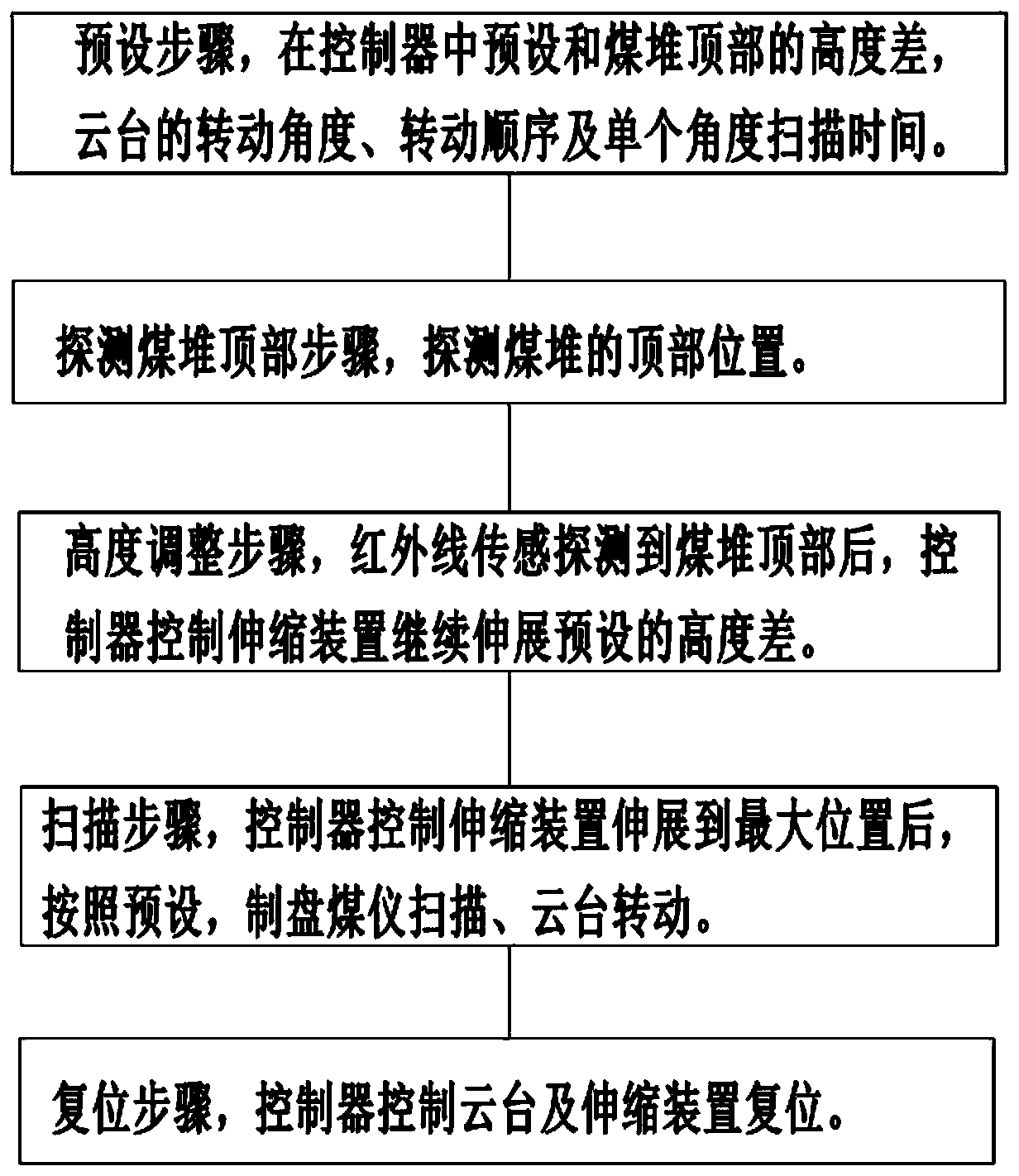

[0038] The height adjustment method used in the coal panning system includes a preset step, a step of detecting the top of a coal pile, a height adjustment step, a scanning step and a reset step.

[0039] Preset step, according to the size of the coal pile, preset the height difference between the scanning device and the top of the coal pile when the scanning device scans, and store the preset height difference in the controller; and preset in the controller The rotation angle and rotation sequence of the pan-tilt and the scanning time of a single angle of the scanner. In this embodiment, the rotation angle and rotation sequence of the pan-tilt pre-stored in the controller are 45 degrees clockwise, and then 90 degrees counterclockwise. The preset scan time for all angles is 20 seconds. The height difference between the scanning device and the top of the coal pile can be set by those skilled in the art according to the specific scale of the co...

Embodiment 2

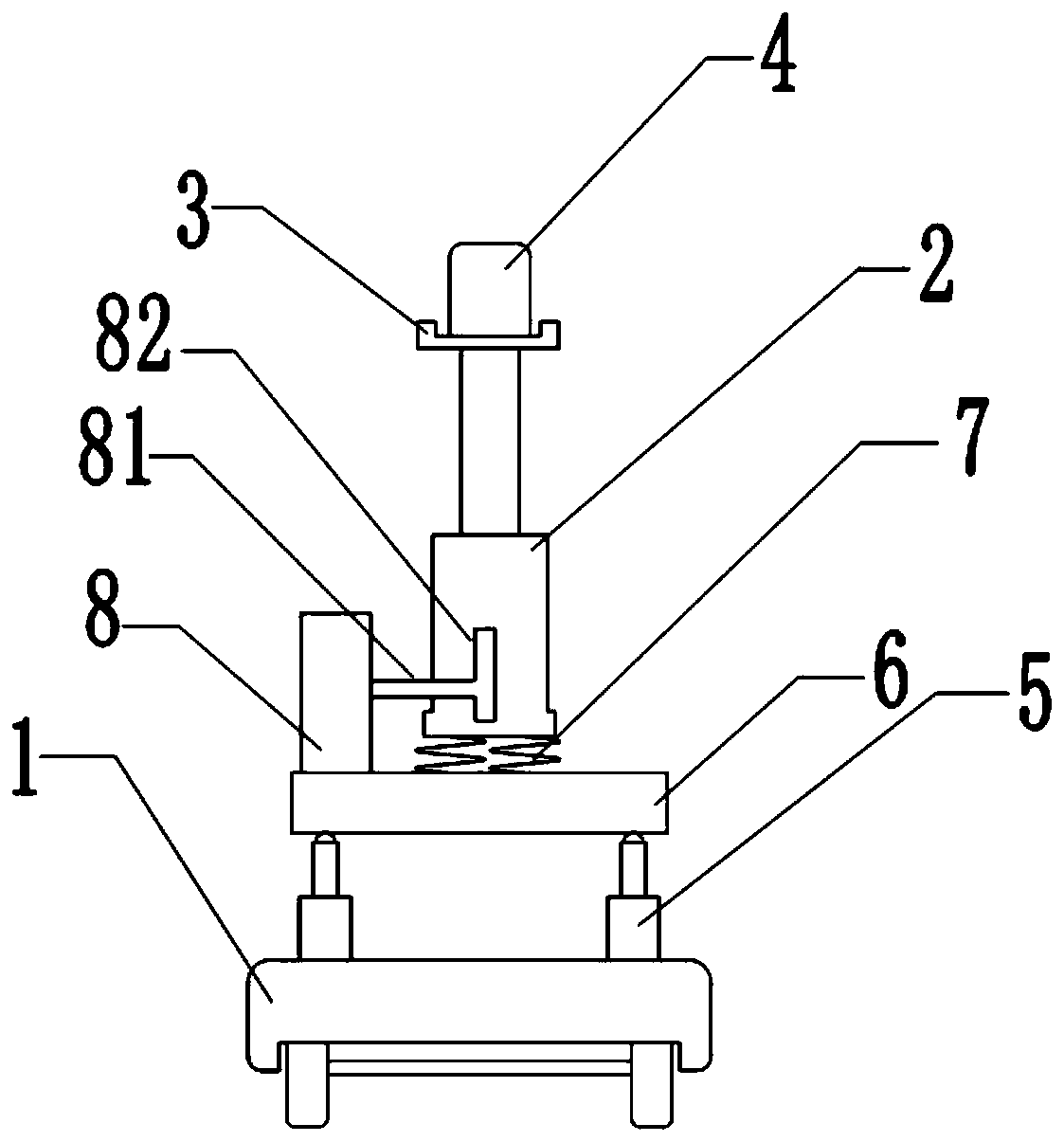

[0048] Such as figure 2 As shown, compared with the first embodiment, the loading vehicle 1 in this embodiment also has a balance bar 5 , an installation base 6 , a support spring 7 and a driving motor 8 .

[0049] Balance pole 5, balance pole 5 is electric push rod, and balance pole 5 has four, and the bottom of balance pole 5 is welded on the loading car 1, and balance pole 5 is electrically connected with controller, and the bottom of four balance poles 5 is connected successively Constitute a rectangle; In the present embodiment, the balance bar 5 is an electric push rod with a stroke of 500 millimeters customized by Zhongshan Elephant Electric Co., Ltd.

[0050] Mounting seat 6, mounting seat 6 is a sealed hollow cuboid, the four corners of the bottom surface of mounting seat 6 are hinged with the tops of four balance bars 5 respectively, mercury is housed in mounting seat 6, and welded on the internal side wall of mounting seat 6 Pressure sensor, there are four pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com