Combustor capable of generating multi-scale controllable turbulence

A multi-scale, burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve inconsistent experimental results, difficult to support theoretical development and model verification, and unable to support turbulent flow and flame interaction mechanism research turbulent combustion model Issues such as verification development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention are described in detail below, the illustrated examples being set forth in the accompanying drawings. The examples described in the drawings are only exemplary, and are only used for explaining the invention, and should not be construed as limiting the invention.

[0024] The invention aims to study the generation of multi-scale controllable turbulent flow and the phenomenon of premixed turbulent flow combustion with controllable scale, solves the defects and deficiencies in the existing turbulent flow combustion test bench device, and provides a goal-oriented and capable Realize variable controlled turbulent burner setup.

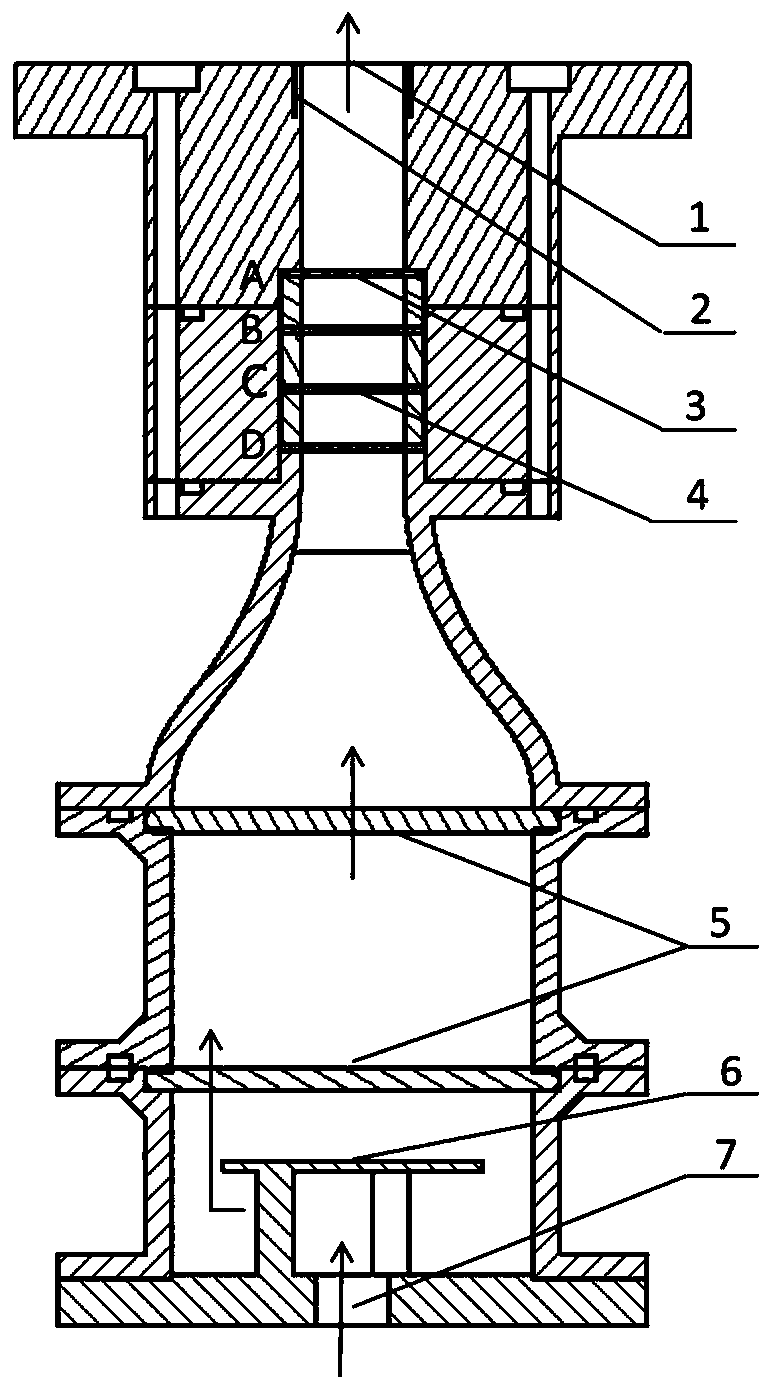

[0025] Such as figure 1 As shown, the turbulent burner of the present invention that can produce multi-scale controllable flow field includes fuel and air inflow mixing device, turbulent flow generation component and top component; The upstream turbulence generation component is connected, and the turbulence generation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com