Device and method for researching influence of coke deposition on reservoir physical properties

A technology for reservoir physical properties and coke deposition, which is used in measurement devices, permeability/surface area analysis, and analysis by nuclear magnetic resonance. The process is simple and easy to operate, the experimental accuracy is high, and the rigor is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical solutions and technical advantages of the present invention clearer, the technical solutions during the implementation of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings.

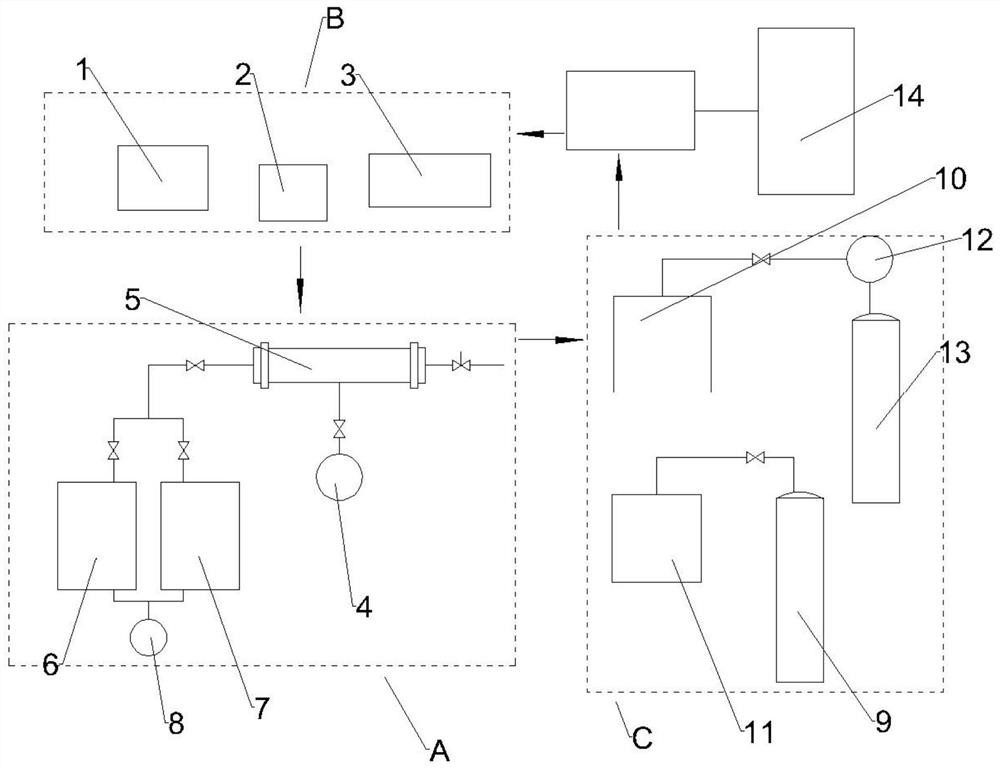

[0044] like figure 1 As shown, a device for studying the influence of coke deposition on reservoir properties, including

[0045] Saturation system A, saturation system A includes a core holder 5, the inlet section of the core holder 5 is provided with an oil storage tank 6 and a water tank 7 in parallel, the core holder 5 is also connected to a confining pressure pump 4, and the oil storage tank 6 and the water tank 7 are connected with the injection pump 8; the saturation system A is mainly used to saturate the core with oil.

[0046] In some embodiments, the oil storage tank 6 and the water tank 7 are intermediate containers filled with heavy oil and water respectively, and the oil st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com