Test device for physical parameters and mechanical properties of yarn

A technology of physical parameters and mechanical properties, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of insufficient precision, yarn performance differences, etc., and achieve accurate results, high accuracy, and tensile modulus values precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, further illustrate the present invention.

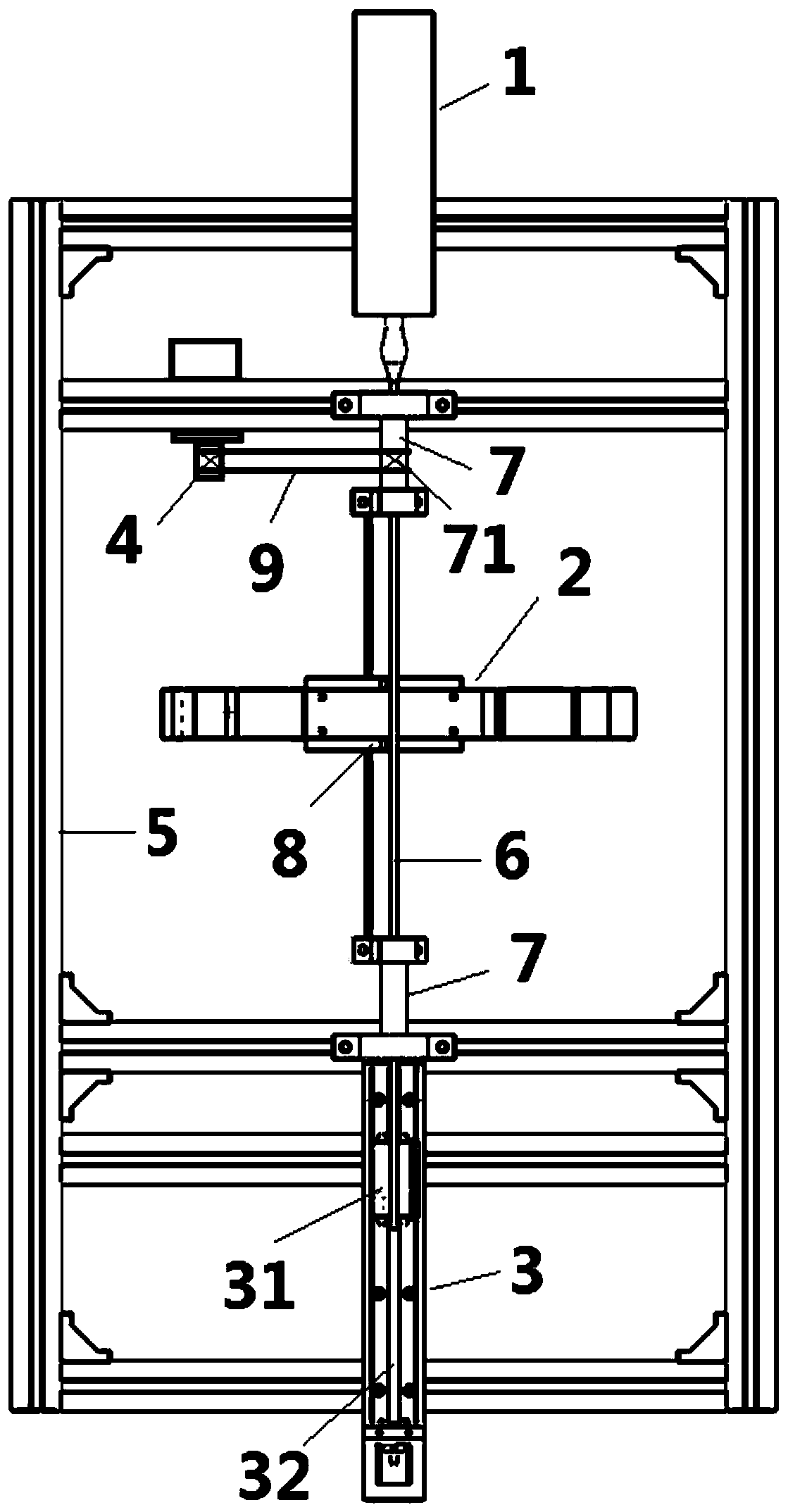

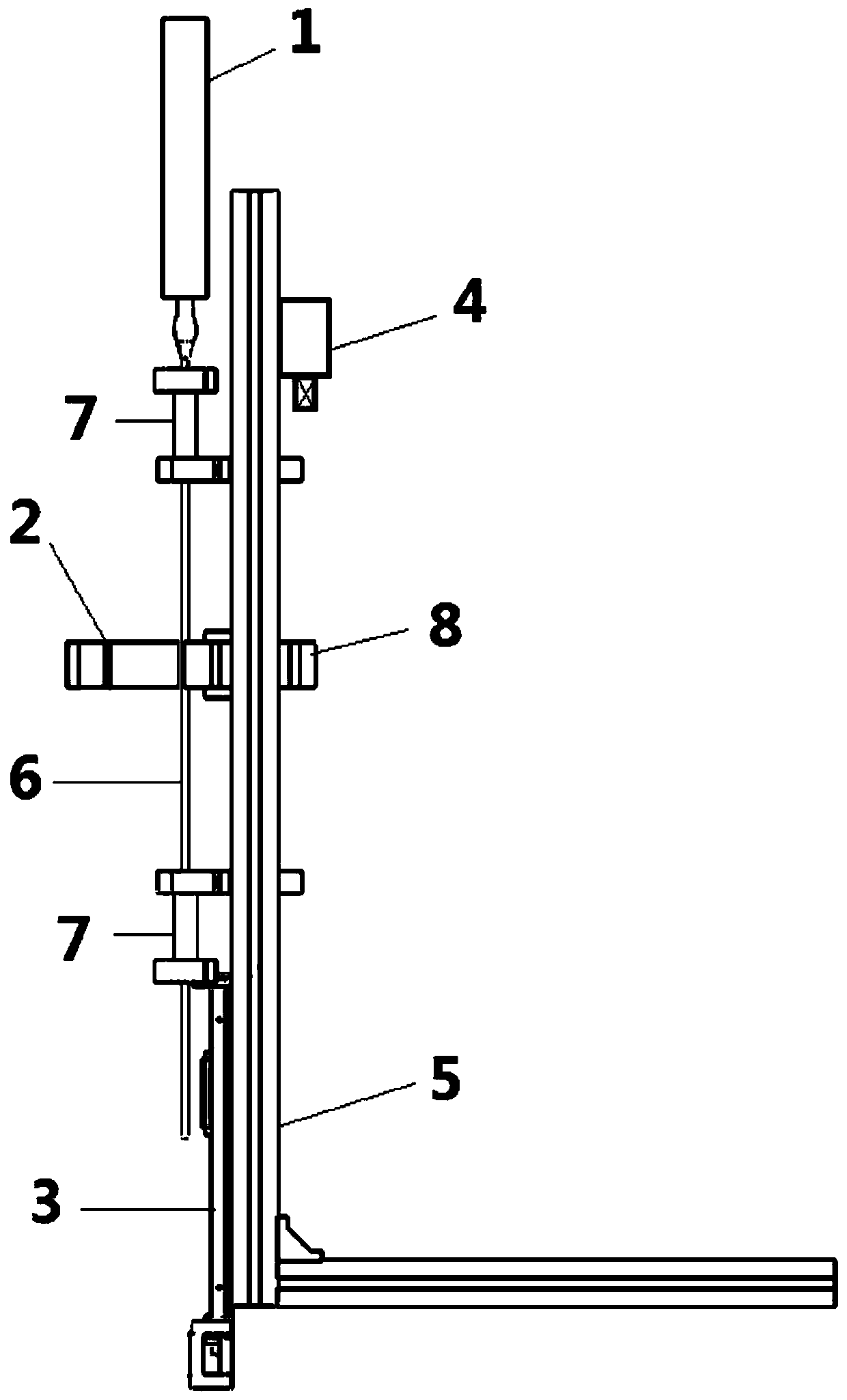

[0025] figure 1 The schematic diagram of the test device for the physical parameters and mechanical properties of the yarn provided in this embodiment, the test device for the physical parameters and the mechanical properties of the yarn includes: a tension meter 1 that can hold the yarn; a non-contact, high-precision Laser measurement sensor 2; linear guide rail 3 for adjusting the yarn state; motor 4 for controlling the circular motion of the laser measurement sensor; outer frame 5 of the measurement device; and modules such as a computer for data processing and analysis.

[0026] Both the tension meter 1 and the linear guide rail 3 are fixed on the outer frame 5 of the measuring device, the linear guide rail 3 is coaxially arranged under the tension meter 1, the tension meter 1 and the linear guide rail 3 are on the same plumb line, and the plumb line is set on the measuring de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com