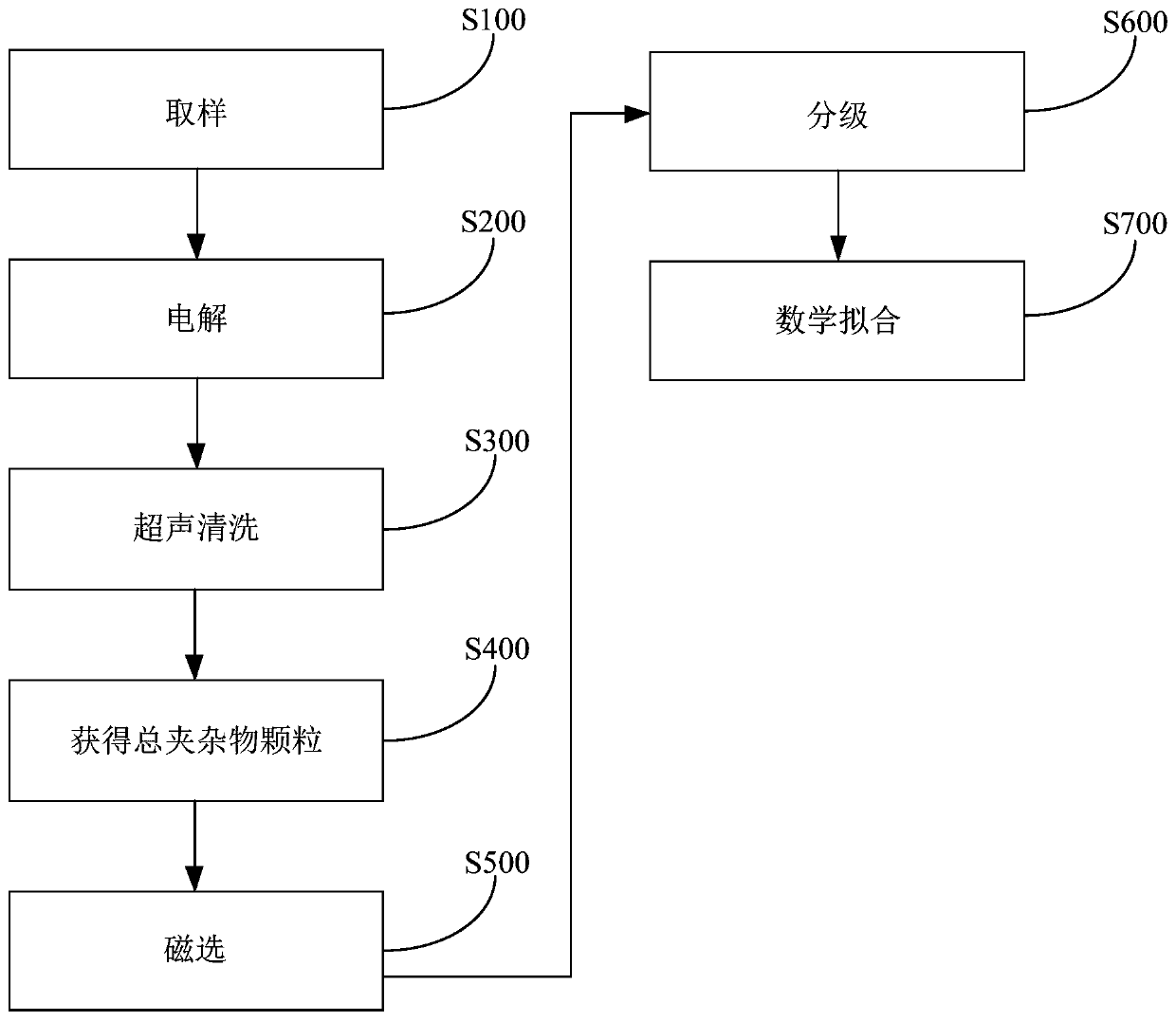

Method for representing distribution of non-metallic inclusions in large-scale steel ingot by electrolytic method

A technology of non-metallic inclusions and inclusions, applied in the field of metal materials, can solve problems such as unsatisfactory, one-sided steel ingots, and needs to be improved, and achieve the effect of improving the quality of steel ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] (1) Preparation for electrolysis

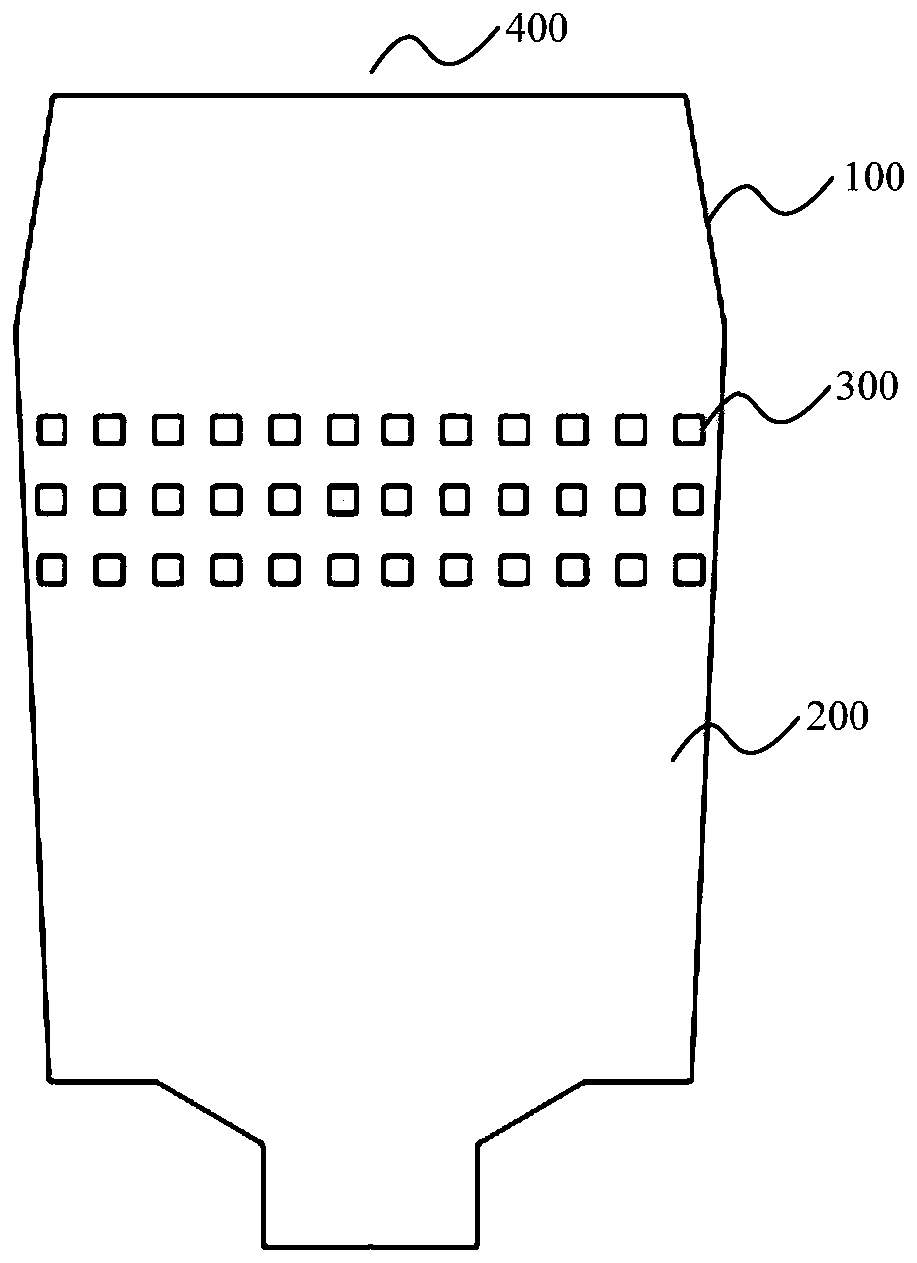

[0084] The steel ingot to be characterized is sectioned on a symmetrical plane, and on the obtained section according to Figure 4 Indicating sampling, the sample is required to be in the shape of a cuboid, with a thickness of 10mm and a length and width of 100mm. A total of 3 groups of samples are taken, which are marked as A, B, and C. Each group takes 6 samples, which are respectively recorded as A1~A6, B1~B6, C1~C6. Drill 3 M5 screw holes with a depth of 15mm at equal distances on one side of each sample to prepare bolts for hanging. The surface of the sample is required to be smooth, oil-free, and rust-free. The electrolyte solution is composed of tetramethylammonium chloride 2wt%, acetylacetone 8wt%, glycerin 5wt%, triethanolammonium 6wt%, and the rest is methanol with a purity of 99.9%.

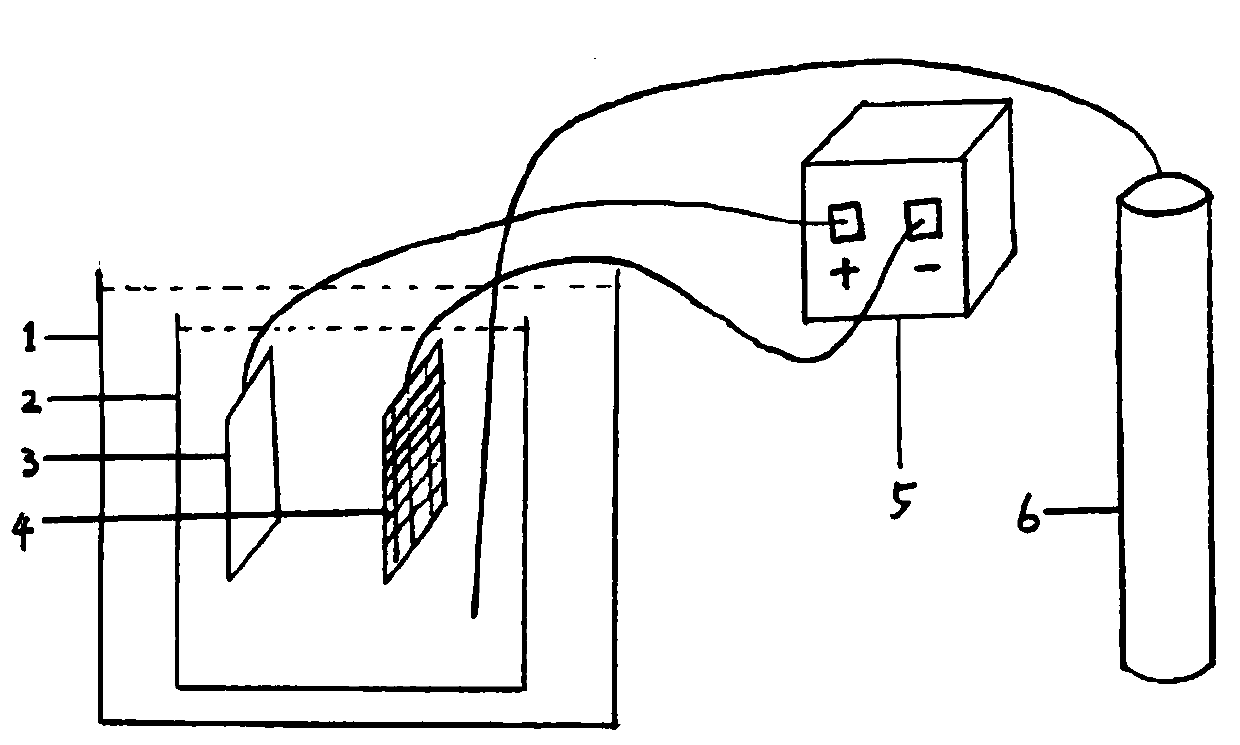

[0085] (2) Electrolysis

[0086] Take the sample as the anode and the barbed wire as the cathode, adjust the electrolysis potential to 1.5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com