Calibrating oxygen sensor of domestic appliance

A technology for oxygen sensors and household appliances, which can be used in home appliances, household heating, kitchen appliances, etc. It can solve the problem that the calibration of lambda detectors has not been disclosed, achieve good user friendliness, improve measurement accuracy, and improve adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

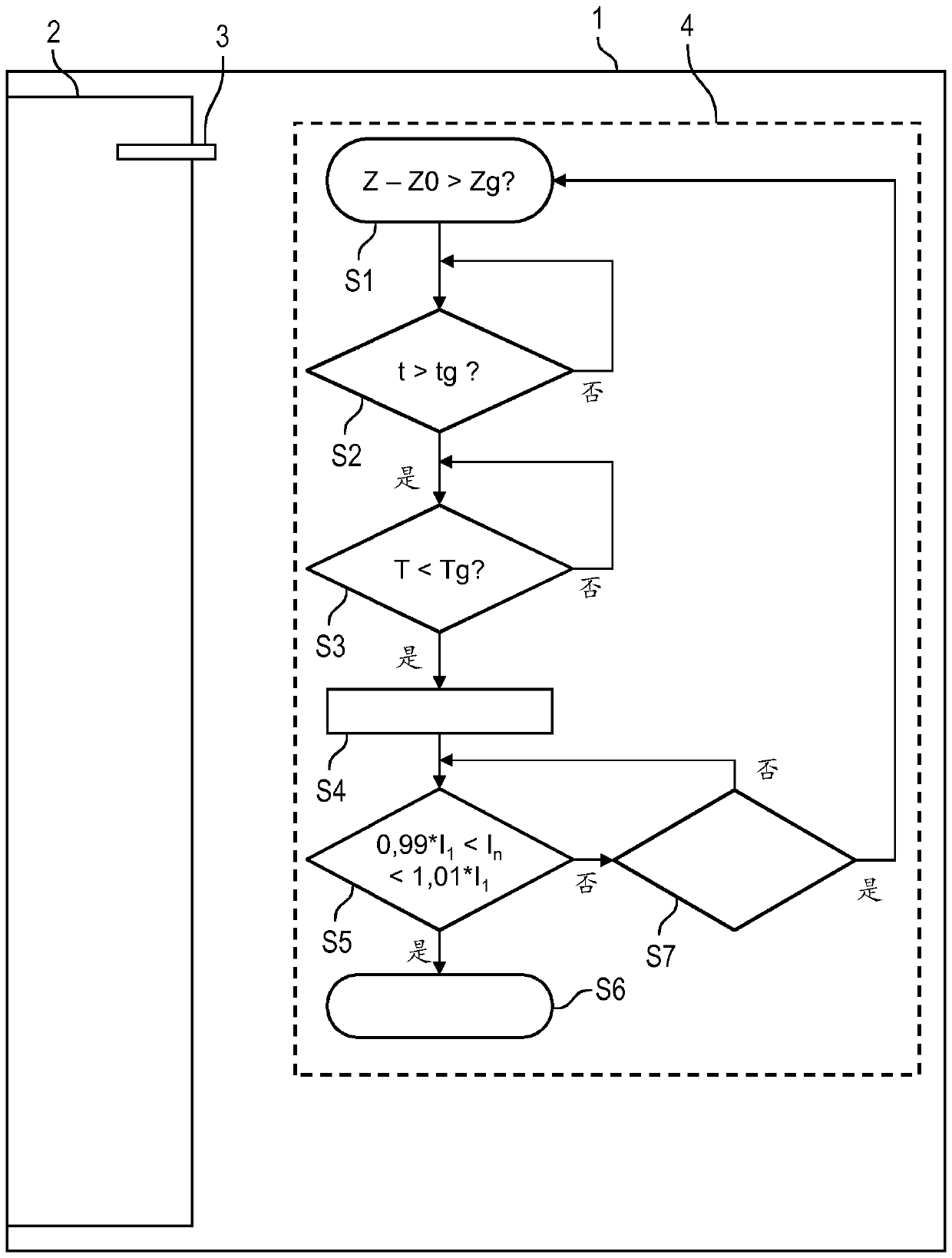

[0044] The domestic appliance in the form of a boiler 1 has a cooking chamber 2 which can be acted upon with steam, an oxygen sensor in the form of a lambda probe 3 and a data processing unit 4 . Data processing unit 4 is designed to determine the water content in cooking chamber 2 on the basis of the measured values of lambda probe 3 . Furthermore, the data processing unit 4 is set up to carry out the method. The data processing unit 4 can be a central control unit for operating the cooking appliance 1 .

[0045] For the method, the data processing unit 4 checks in a first step S1 whether the state parameter in the form of the duration Z-Z0 since the time Z0 of the last calibration is greater than the specified duration The time constitutes the threshold in the form of Zg. In other words, it is checked in step S1 whether the duration Zg has elapsed since the last calibration carried out at time Z0 until the current time Z. Zg can be 30 hours, for example. If this is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com