Single-bud-segment sugarcane planting machine

A technology for planting machines and sugarcane, which is applied to planting methods, agricultural machinery and tools, shovels, etc. It can solve the problems of waste of sugarcane seeds and uneven placement of seeds, and achieve the effects of avoiding waste, reducing labor force, and improving the efficiency of seed placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

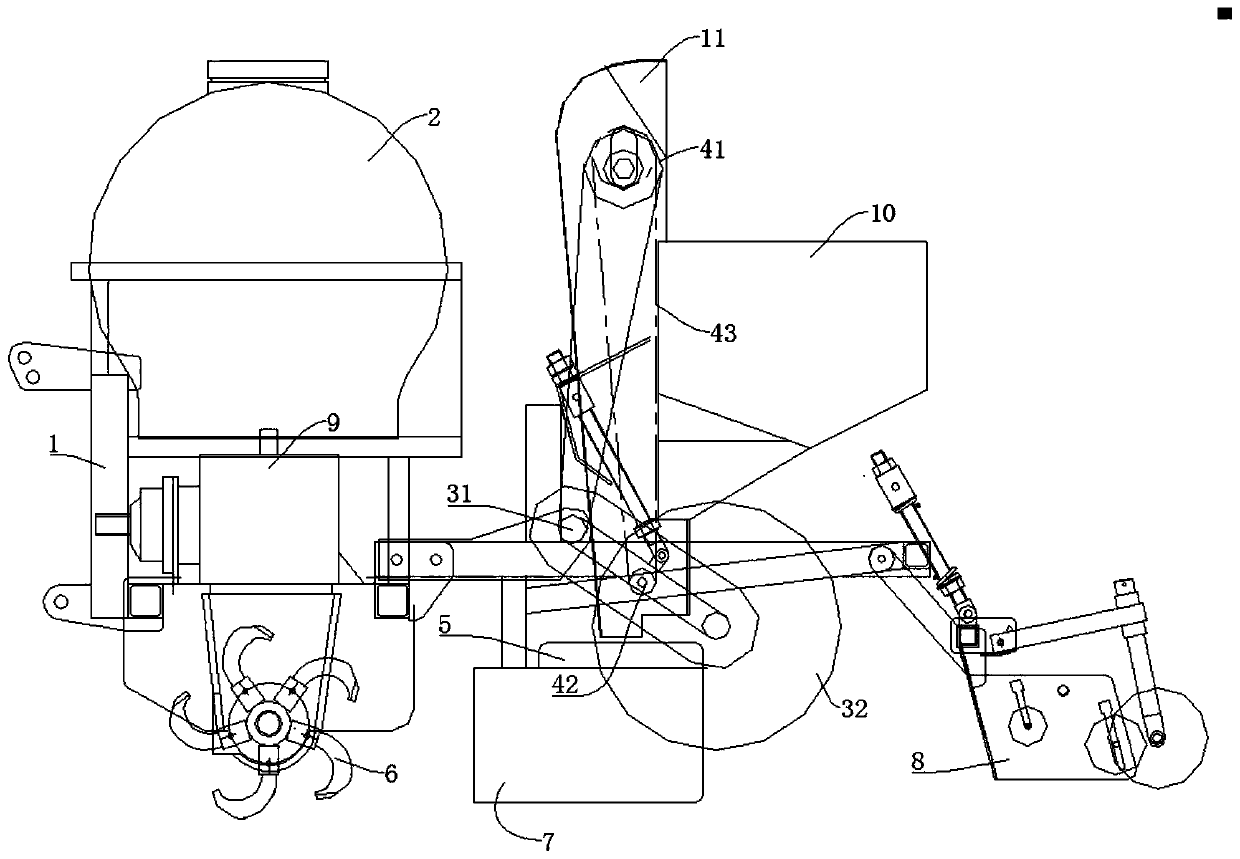

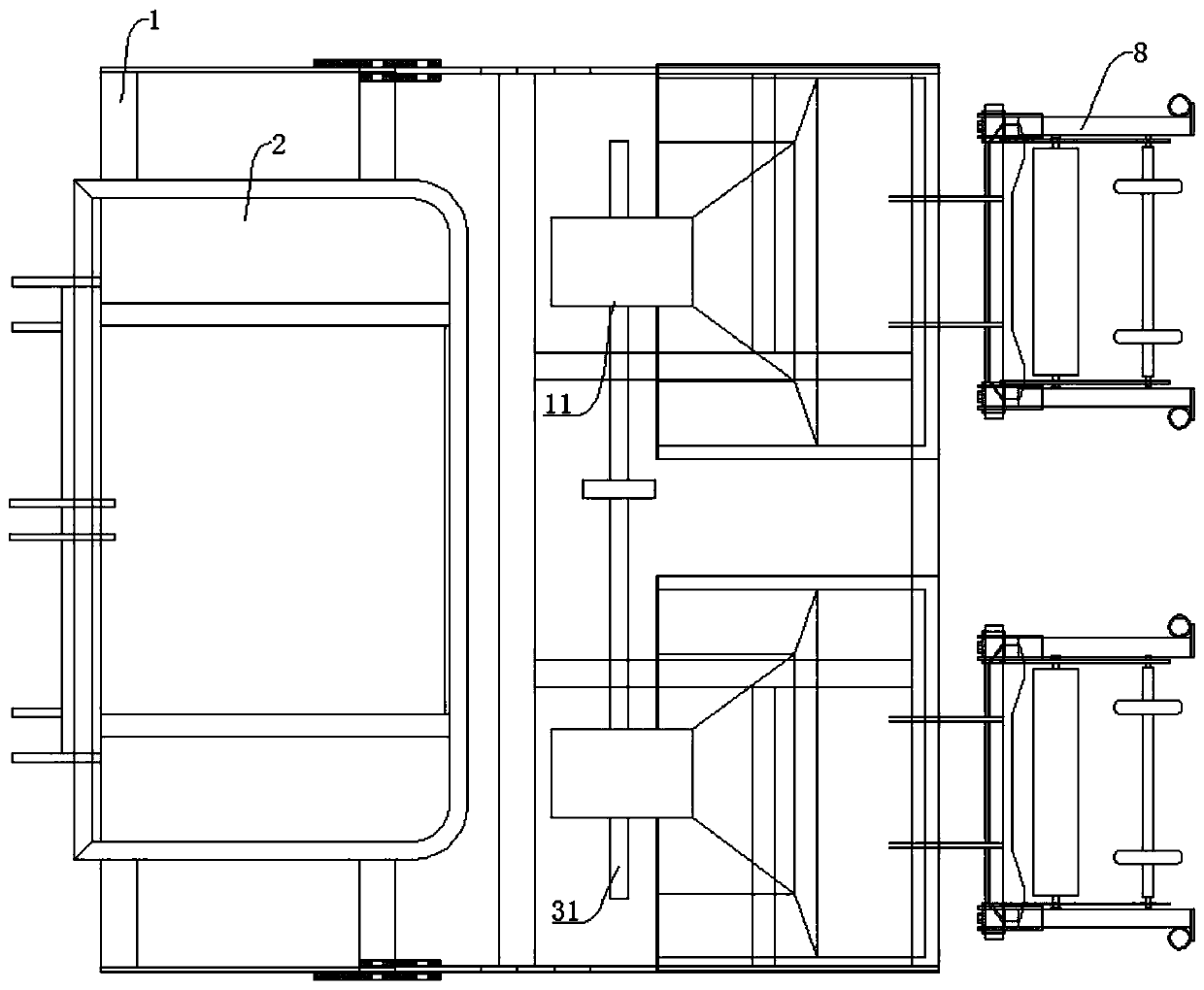

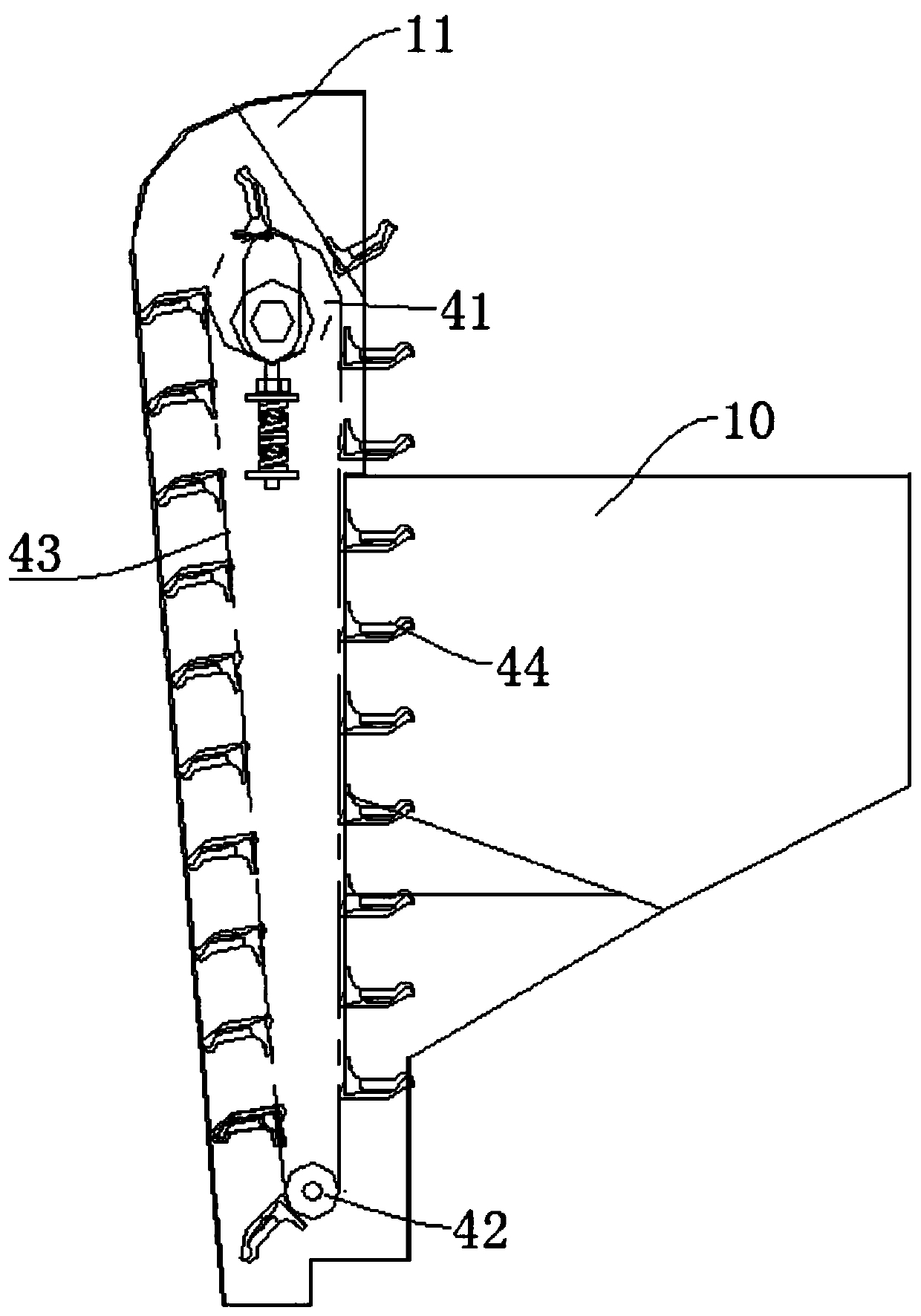

[0039] Such as figure 1 , figure 2 as well as image 3 As shown, a single-bud section sugarcane planter includes a frame 1, a seed box 10, a seed placement device and a drive mechanism are installed on the frame 1, the seed placement device includes a scooping mechanism and a delivery box 11, and the scooping mechanism includes The first transmission wheel 41, the second transmission wheel 42, the transmission member 43 and the seed scoop 44, the first transmission wheel 41 and the second transmission wheel 42 are respectively rotatably mounted on the frame, and the first transmission wheel 41 is located on the second transmission wheel. Above the two transmission wheels, a transmission member 43 is installed between the first transmission wheel 41 and the second transmission wheel 42. The transmission member 43 is a transmission belt or a transmission chain, which has good transmission effect and is easy to install. The transmission member 43 is provided with some equidist...

Embodiment 2

[0043] Such as Figure 4 and Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that two transmission members 43 are arranged side by side, and the seed scoops 44 on the two transmission members 43 are arranged in a staggered manner, so that the sugarcane seeds are staggered , so that the lifting speed of the seed scoop 44 can be doubled compared with that of a single chain, so that the rate of seed leakage is greatly reduced. The left and right sides of frame 1 are respectively provided with a seed placement device, and the frame 1 is provided with left and right seed placement devices, which can complete the planting of two rows of sugarcane at one time.

[0044] The single-bud sugarcane planter of the present application also includes a rotary tillage device 6 , a fertilization device 2 and a soil-covering film-covering device 8 . Rotary tillage device 6 is installed on frame 1 front, and rotary tiller dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com