Seedling taking machine for bottomless seedling tray

A technology of bottomless seedlings and seedling trays, which is applied in the field of seedling picking machines, can solve the problems of high labor intensity, low transplanting efficiency, and unstable quality, and achieve the effects of saving costs, reducing labor intensity, and being easy to manufacture and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

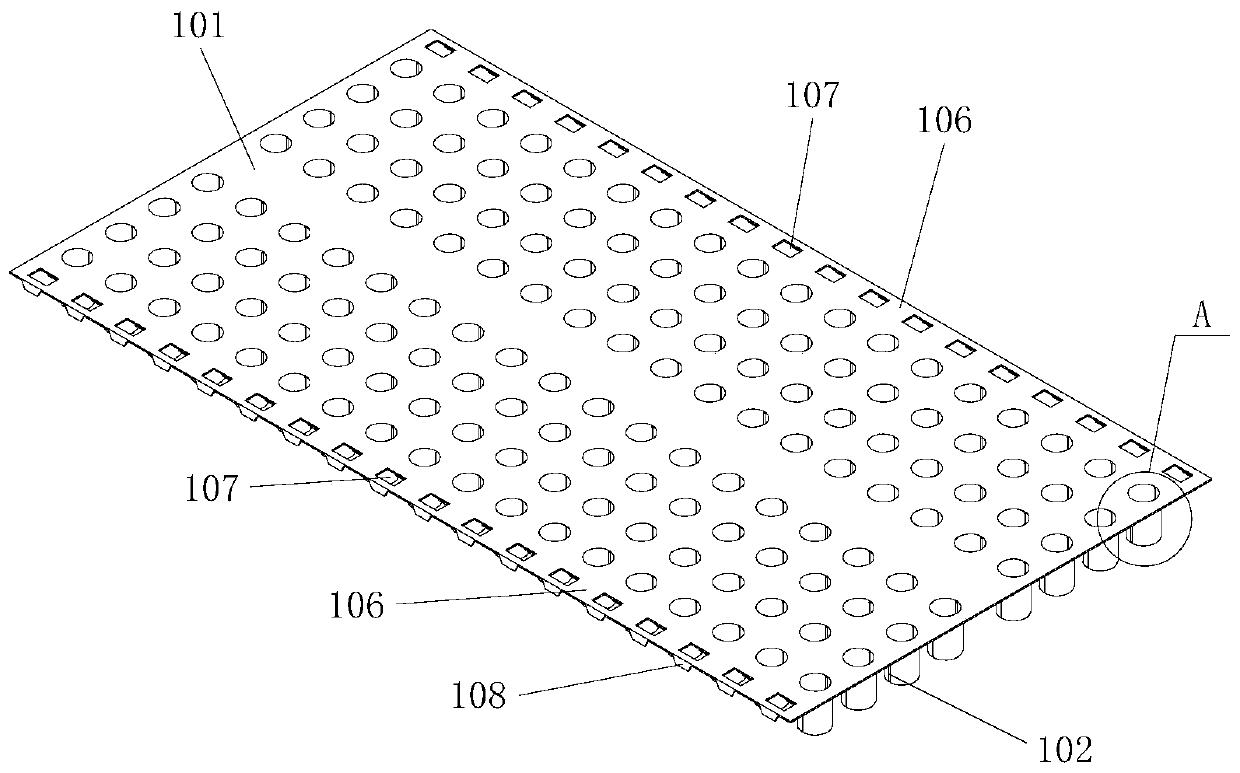

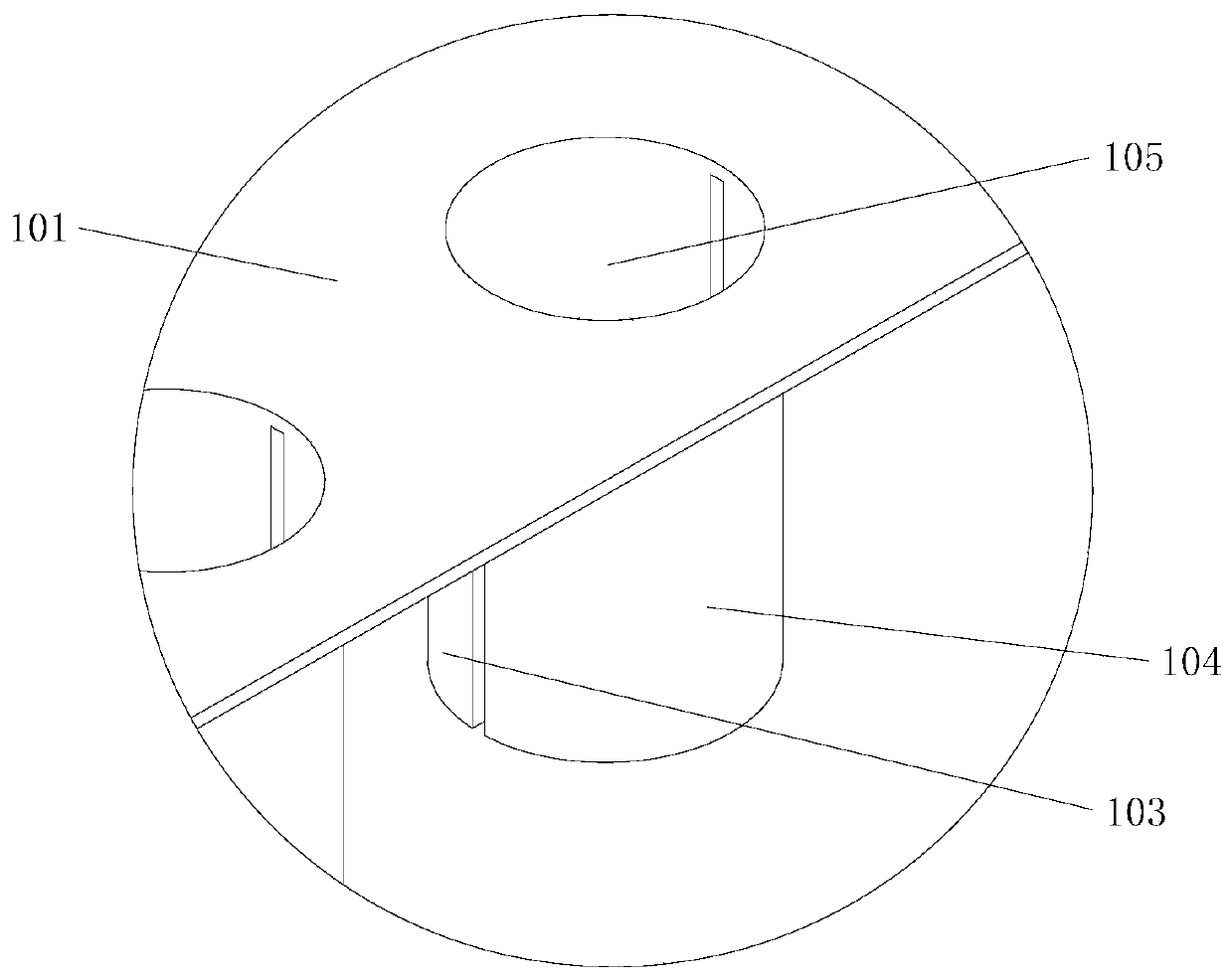

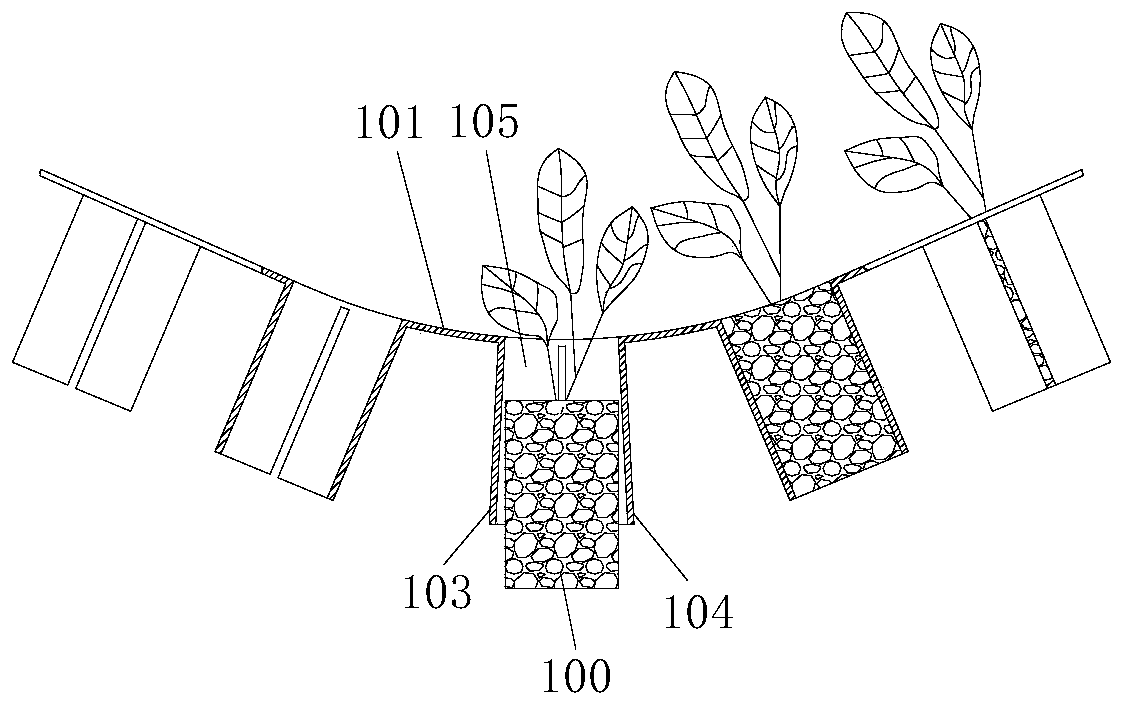

[0025] The seedling extraction machine for bottomless seedling trays of this embodiment, such as Figure 1 to Figure 3 As shown, the bottomless seedling tray includes a top plate 101 that can be bent and deformed. The top plate 101 is provided with a number of pots 102. The pot 102 includes a front pot wall 103 and a rear pot wall 104 connected to the top plate 101, a front pot wall 103 and a rear pot wall 103. There are gaps between the pot walls 104 and enclose the through-hole pot holes 105 for accommodating the pot seedlings 100. The two sides of the top plate 101 are respectively provided with driving matching parts 106, such as Figure 4 to Figure 7 As shown, the seedling extraction machine includes a frame 1, on which is installed a deformation drive device 3 for forcing the top plate 101 to bend and deform so that the bottom ends of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com