Non-slip mat

A technology of anti-slip mat and mat body, applied in the field of floor mats, can solve the problems of poor anti-skid ability, poor anti-slip effect of floor mats, and inability to form negative pressure in the disc cavity, etc., to achieve enhanced anti-skid ability and flexible layout design , enhance the effect of anti-slip ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

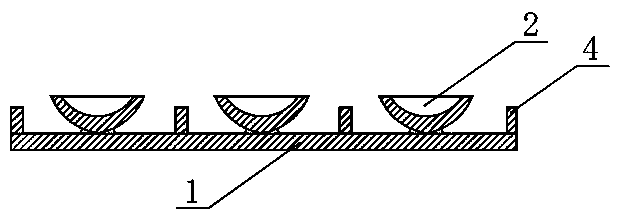

[0036] Embodiment 1: as figure 1 As shown, a non-slip pad includes a pad body 1, nine suction cups 2 are arranged on the lower surface of the pad body 1, and one hundred and twenty-one bosses 4 are also arranged on the lower surface of the pad body 1. The end face of the mouth of the sucker 2 is higher than the free end face of the boss 4, and the inner bottom of the sucker 2 is lower than the free end face of the boss 4.

Embodiment 2

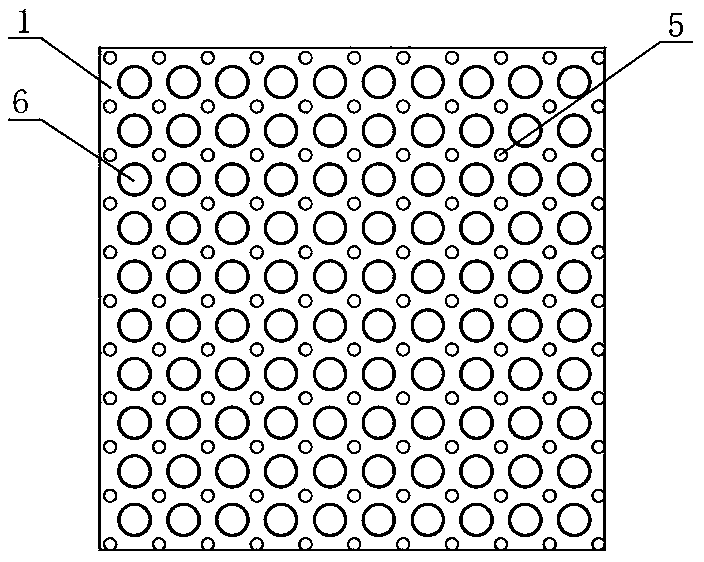

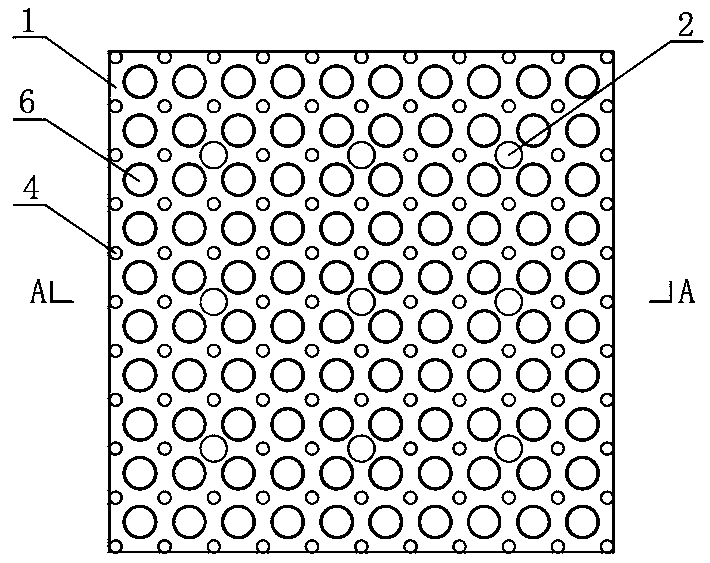

[0037] Embodiment 2: as figure 2 , image 3 and Figure 4 , a non-slip pad, comprising a pad body 1, nine suction cups 2 are arranged on the lower surface of the pad body 1, and one hundred and twenty-one bosses 4 are also arranged on the lower surface of the pad body 1.

[0038] Each suction cup is connected with the pad body 1 through a connecting shaft 3 . The opening end surface of the suction cup 2 is higher than the free end surface of the convex post 4, and the inner bottom of the suction cup 2 is lower than the free end surface of the convex post 4, that is, the length of the convex post 4 is less than the connecting shaft 3 plus the thickness of the inner bottom of the suction cup 2 and the thickness of the suction cup 2. The sum of the depth of the cavity and the length of the boss 4 are greater than the sum of the connecting shaft 3 and the wall thickness of the inner bottom of the suction cup 2 .

[0039] One hundred and twenty-one convex cakes 5 are arranged o...

Embodiment 3

[0040] Embodiment 3: The inner bottom of the suction cup 2 is provided with a settling tank 7 extending inward until it enters the pad body 1 .

[0041] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com