Waste heat utilization type steel plate preheating device

A technology of preheating device and shaped steel plate, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of unfavorable energy cycle full utilization, heat loss, waste of resources, etc., to facilitate collection and detection, reduce Heat loss, ensure full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

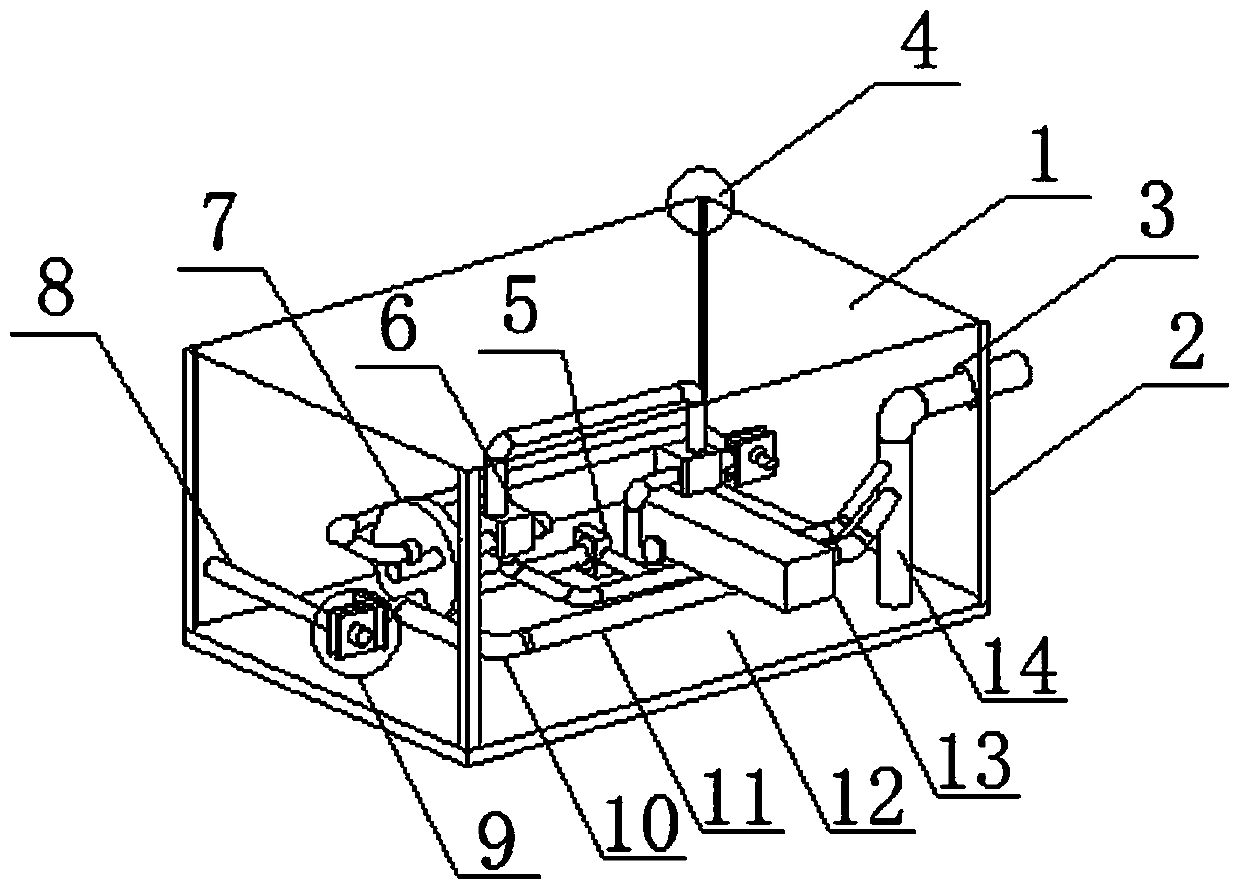

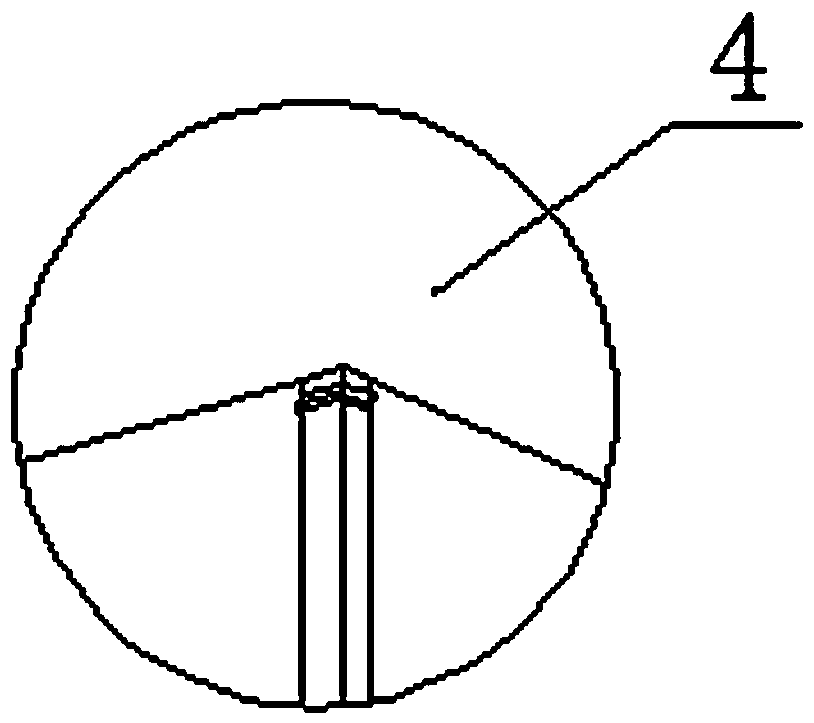

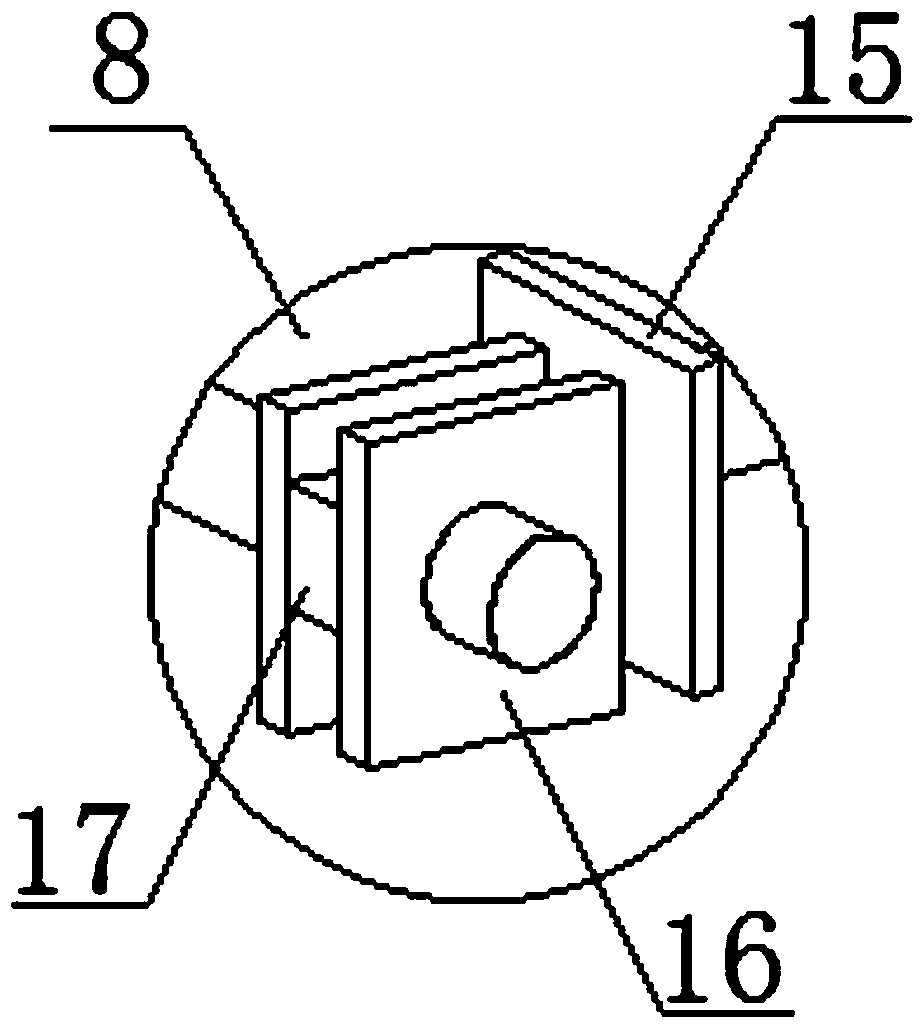

[0016] see Figure 1-Figure 3 , this embodiment includes a housing 1, a bracket 2 and a purification box 13, the top of the bracket 2 is movably connected to the steel frame 4, and the outer side of the bracket 2 is installed with the housing 1, the bottom of the housing 1 is provided with a bottom plate 12, and the side arm of the housing 1 is provided with a through Hole 3, the inner side of through hole 3 is provided with air outlet pipe 14, the inner side arm of shell 1 is connected to inlet pipe 8, and one end of inlet pipe 8 is equipped with air leakage valve 9, which includes detection port 16, shut-off plate 15 and sealing box 17, One end of the sealing box 17 is connected to the cut-off piece 15, and one end of the sealing box 17 is connected to the detection port 16, the side of the leakage valve 9 is provided with a return box ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap