Medium and low speed magnetic levitation F-rail machining forming cutter and axial adjusting method of forming cutter

A processing and forming, maglev technology, applied in the direction of manufacturing tools, metal processing equipment, milling cutters, etc., to save time, ensure the processing accuracy requirements, reliable and effective processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

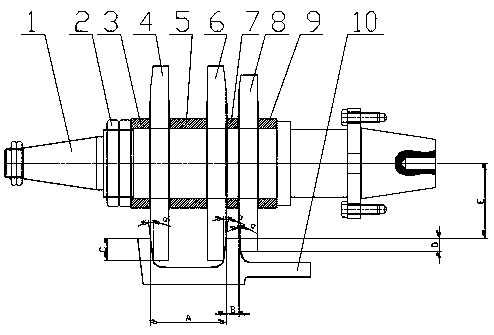

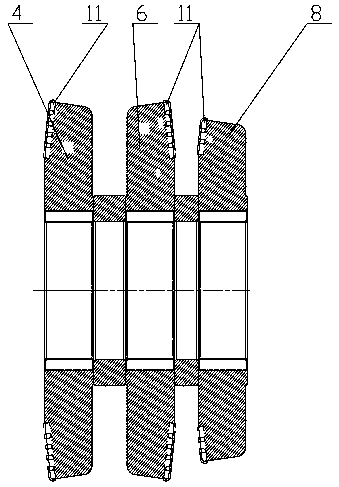

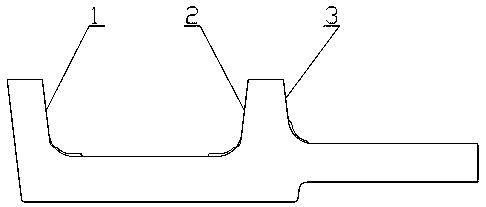

[0014] Embodiment 1: with reference to attached figure 1 —3. A medium-low speed maglev F-rail processing forming tool, including F-rail ( image 3 ), the first forming disc milling cutter 4, the second forming disc milling cutter 6 and the third forming disc milling cutter 8 are connected in series through the cutter shaft 1 and between the first forming disc milling cutter 4 and the second forming disc milling cutter 6 A first spacer 5 is placed, a second spacer 7 is placed between the second forming disc milling cutter 6 and the third forming disc milling cutter 8, and the positioning sleeve 9 is located on the cutter shaft 1 and is used for positioning the third forming disc milling cutter Cutter 8, compression sleeve 3 are enclosed within on the cutter shaft 1 and after the first forming disc milling cutter 4 is compressed, are positioned by the tightening round nut 2 that is screwed on the cutter shaft 1.

[0015] The outer surface of the first forming disc milling cutt...

Embodiment 2

[0022] Embodiment 2: On the basis of Embodiment 1, a method for axial adjustment of the forming cutter for medium and low-speed maglev F rail processing: adjust the first forming disc milling cutter 4 and the second forming disc milling cutter 6 through the positioning sleeve 9 and the axial position of the third forming disc milling cutter 8 on the tool bar, so that the cutter head processing surfaces of the first forming disc milling cutter 4, the second forming disc milling cutter 6 and the third forming disc milling cutter 8 are respectively in line with the processed The F rail surface forms a complete fit after machining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com