Automatic positioning and carrying device for motor rotor assembling production line

An assembly line and automatic positioning technology, which is applied to conveyor objects, transportation and packaging, metal processing, etc., can solve the problems of inconvenient operation, long time consumption, and large investment in motor rotor clamping and positioning, saving time, The effect of high production efficiency, improved positioning accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

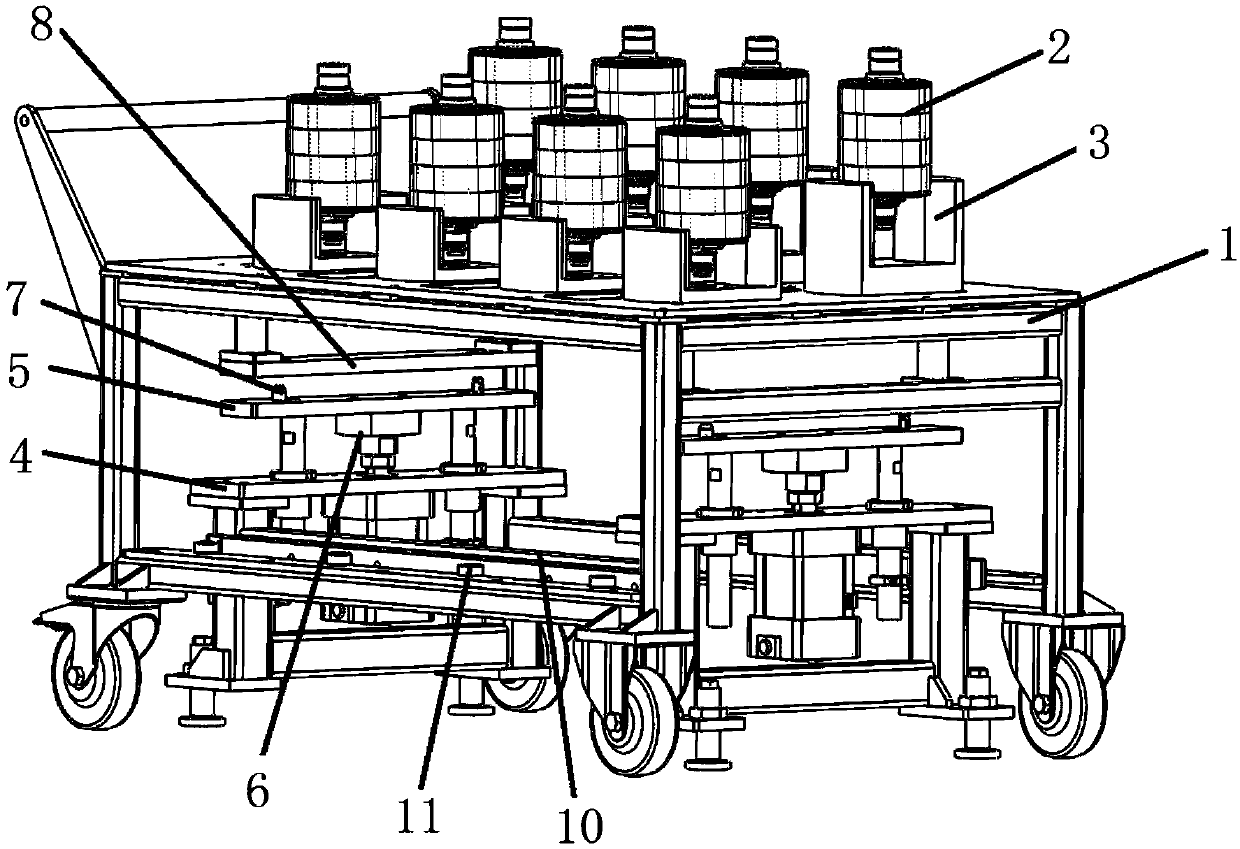

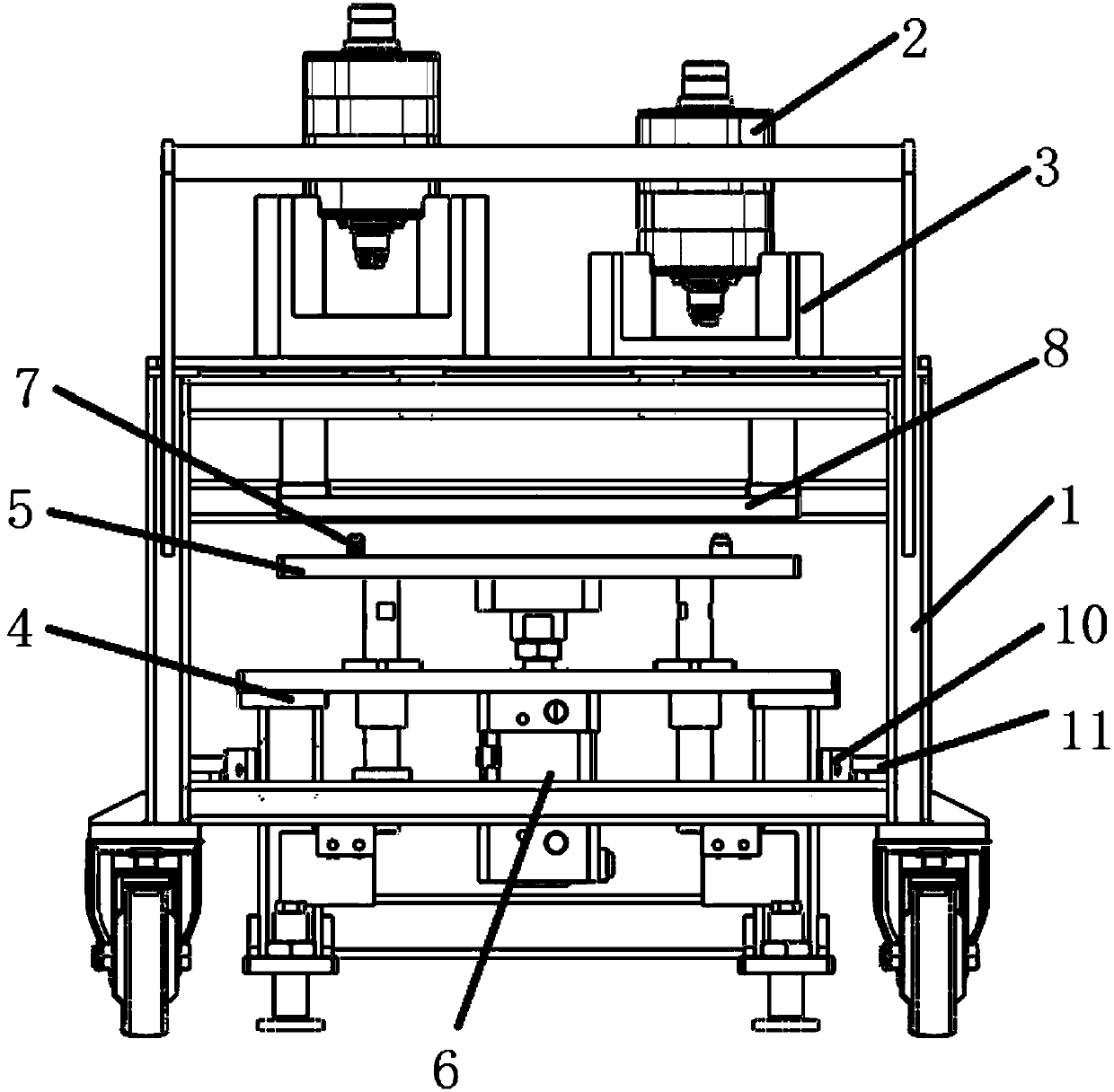

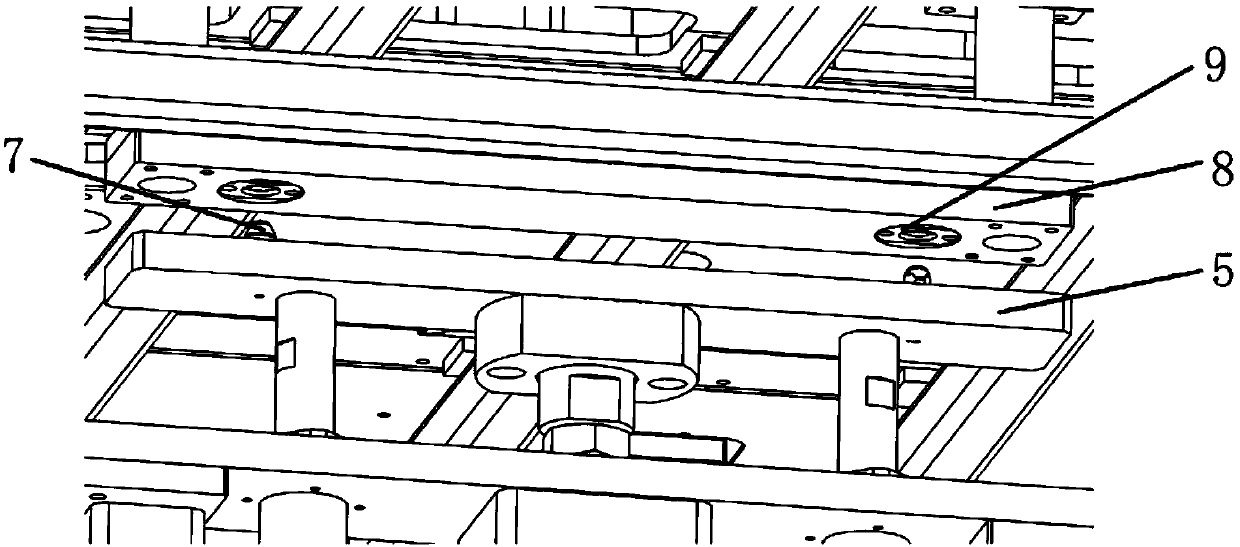

[0027] Such as Figure 1~3 As shown, an automatic positioning carrying device for the motor rotor assembly production line includes a carrying trolley body 1, the carrying surface of the carrying trolley body 1 is provided with a clamping mechanism 3 for clamping the motor rotor 2, and the clamping mechanism 3 includes a plurality of The chuck is used to fix the motor rotor 2. The automatic positioning carrying device also includes a positioning mechanism, which is fixed on the ground. The positioning mechanism includes a positioning stopper arranged at the end of the movement of the carrying trolley body 1, which is not shown in the figure of this embodiment. Draw the positioning block. The main function of the positioning block is to block the forward movement of the carrying trolley body 1, and then realize the positioning of the carrying trolley body 1. The positioning mechanism also includes a positioning pin assembly moving in the vertical direction, and the corresponding...

Embodiment 2

[0033] In this embodiment, there are 2 locating pin assemblies, and 3 locating pins 7 in each locating pin assembly, and then the whole trolley body 1 is positioned by 6 locating pins 7, and the rest are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com