Impurity removal assembly and cotton gin

A technology of a gin and an assembly, applied in the direction of separating plant fibers from seeds, etc., can solve problems such as inconvenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

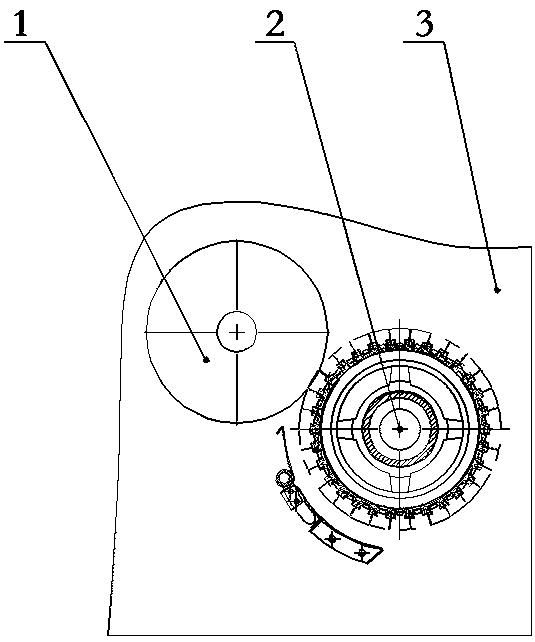

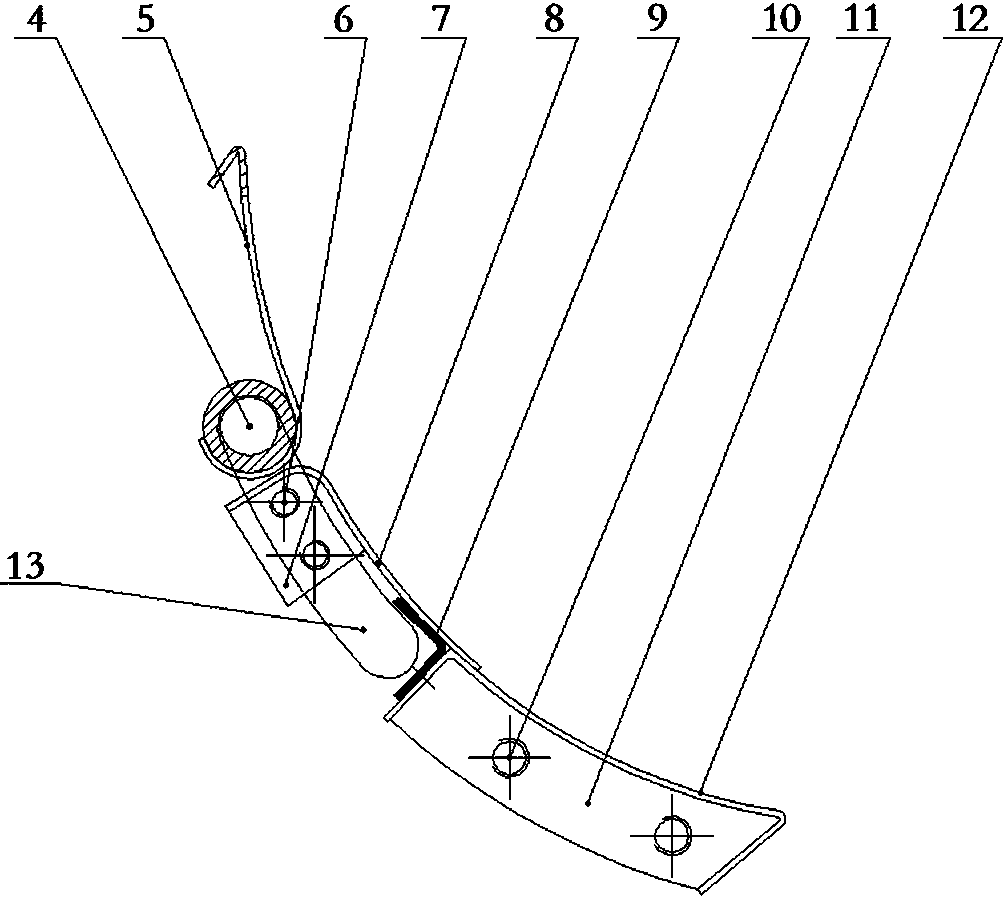

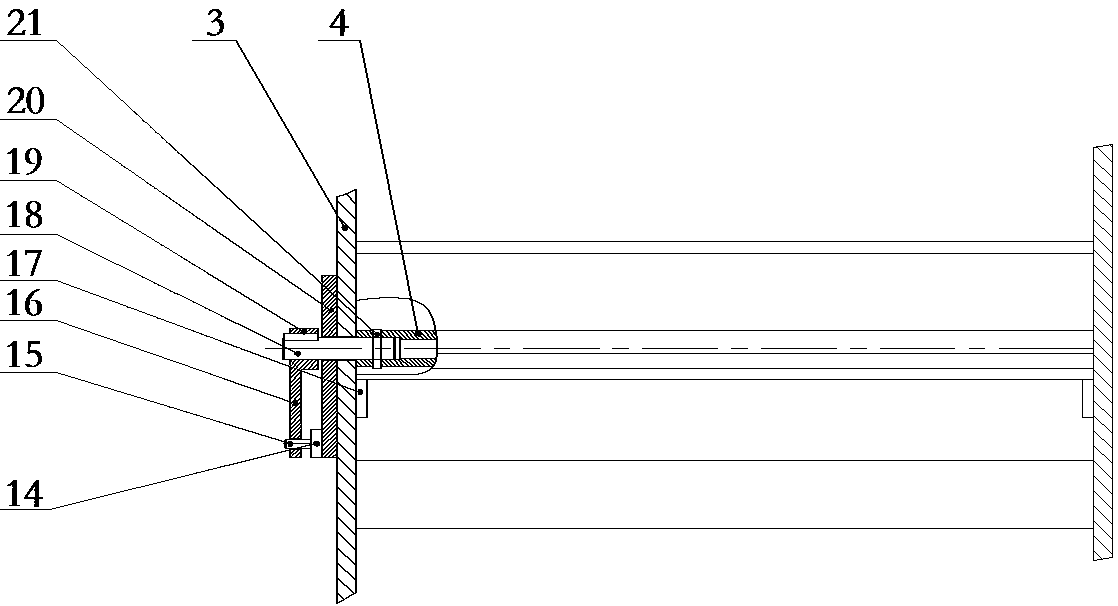

[0054] figure 1 Shown is a part of the structure of the cotton gin, which is included in the rear box of the cotton gin. On the cotton gin, its most basic reference frame is the front and rear, and its three working boxes are the front box, the middle box and the rear box in the front and back directions. box. figure 1 The left side in the figure is the front side of the cotton gin, and the right side is the rear side of the cotton gin. Perpendicular to the paper surface, it can generally be referred to as the left-right direction. The left-right direction is usually the width direction of the cotton gin, and the width determines the width of the cotton gin, which is also the axial direction of various axes on the work box, for example Figure 4 The axial direction of the saw barrel shaft 26 and the brush barrel shaft 27 shown in .

[0055] Based on general common sense, the range contained in the workbox is called inside, and the opposite is called outside.

[0056] exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com