A construction method for a high-altitude cantilevered formwork support frame

A formwork support and construction method technology, applied in formwork/formwork/work frame, scaffolding for building structure support, building structure support, etc., can solve problems such as difficulty in meeting structural safety requirements, waste of materials, and strong wind loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

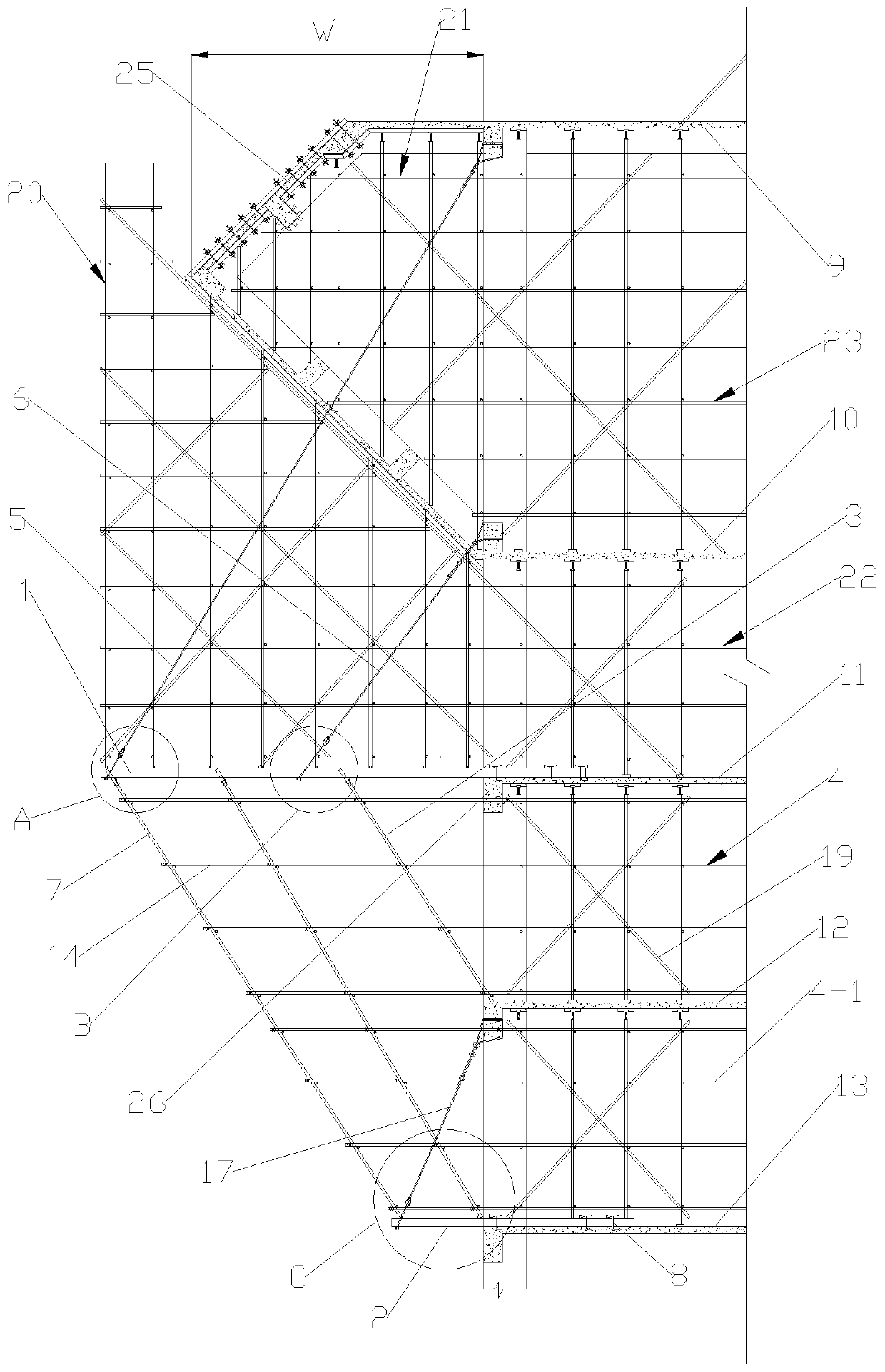

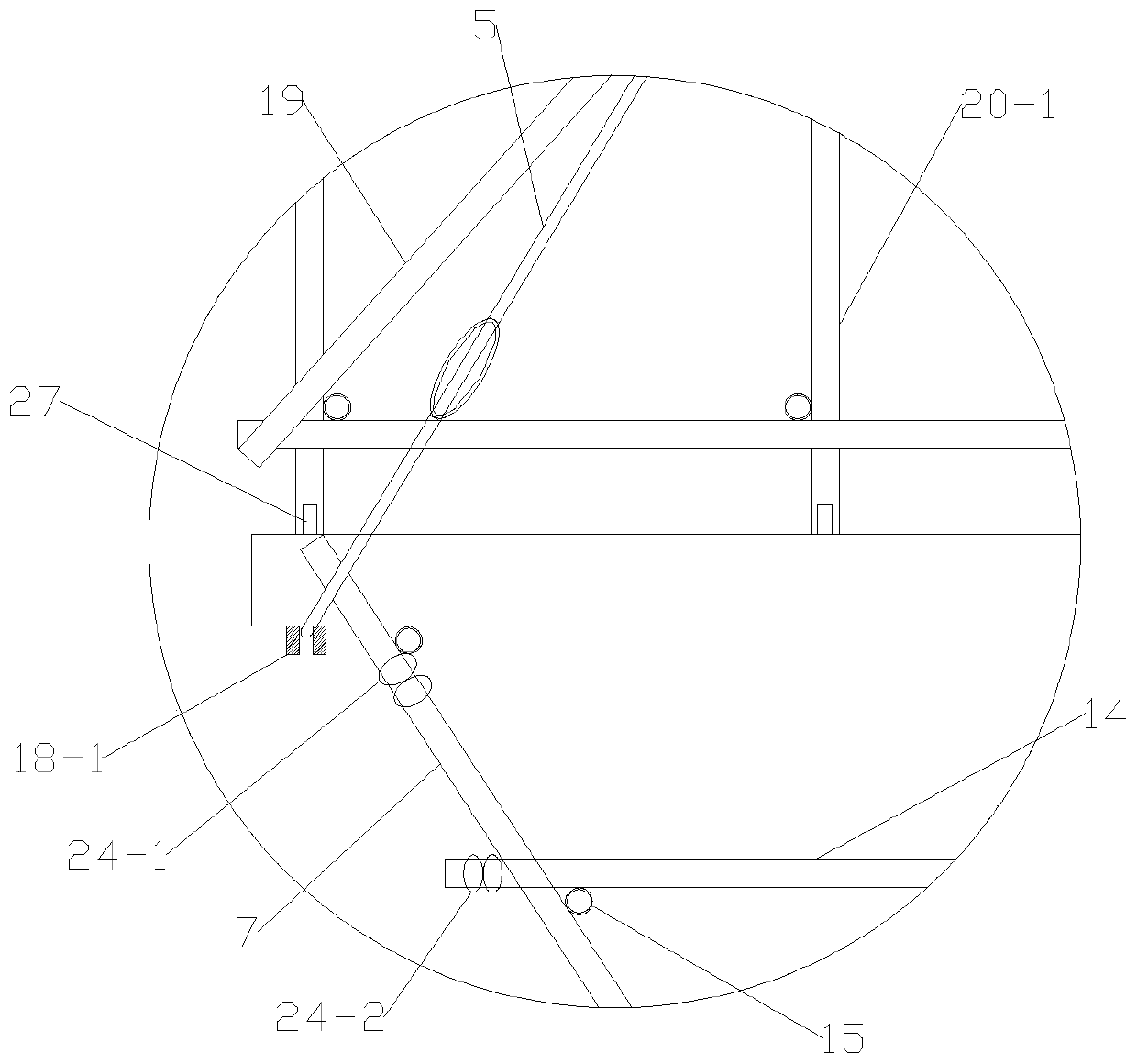

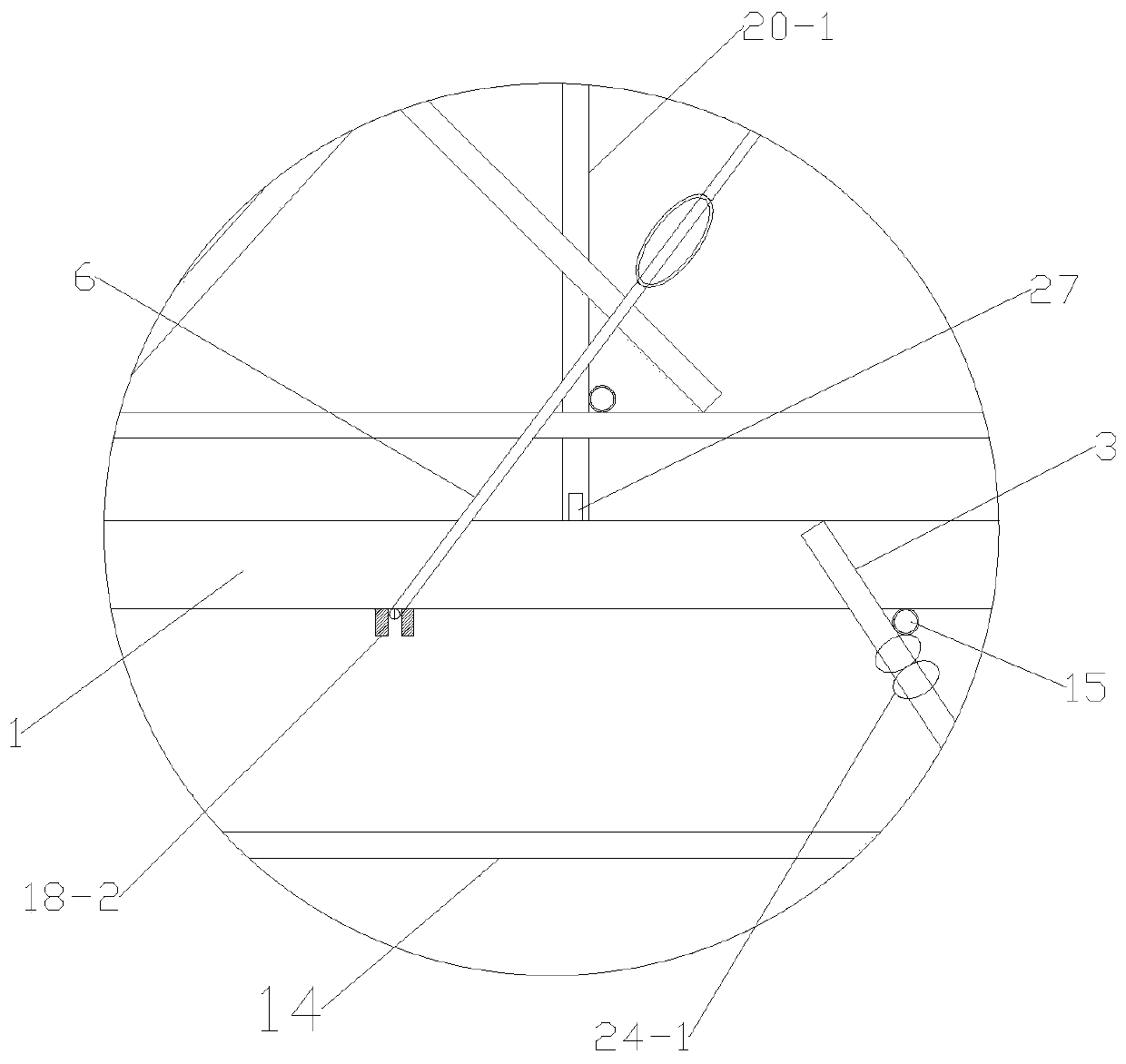

[0067] like figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6A construction method for a high-altitude cantilevered formwork support frame is shown, the high-altitude cantilevered formwork support body includes a cantilevered steel support platform arranged on a building structure and is located on the upper part of the cantilevered steel support platform and is used for construction The formwork support frame of the cantilever structure 25, the height of the cantilever structure 25 is 2H, wherein, H is the height of the first floor of the building structure, and the formwork support frame includes an external formwork support arranged on the outside of the cantilever structure 25 frame 20 and the internal formwork support frame 21 arranged inside the cantilever structure 25, and the upper part of the upper cantilevered steel girder 1 is provided with a plurality of vertical rods 20-1 for positioning the external formwork support frame 20 The vertical rod anti-sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com