Material information updating method, device and production control equipment

A technology for production control and information update, applied in the direction of collaborative operation of devices, instruments, computing, etc., can solve the problems of irregular material shape, difficulty in scanning and reading the content of electronic tags, etc., to improve the breadth and reduce the difficulty of reading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

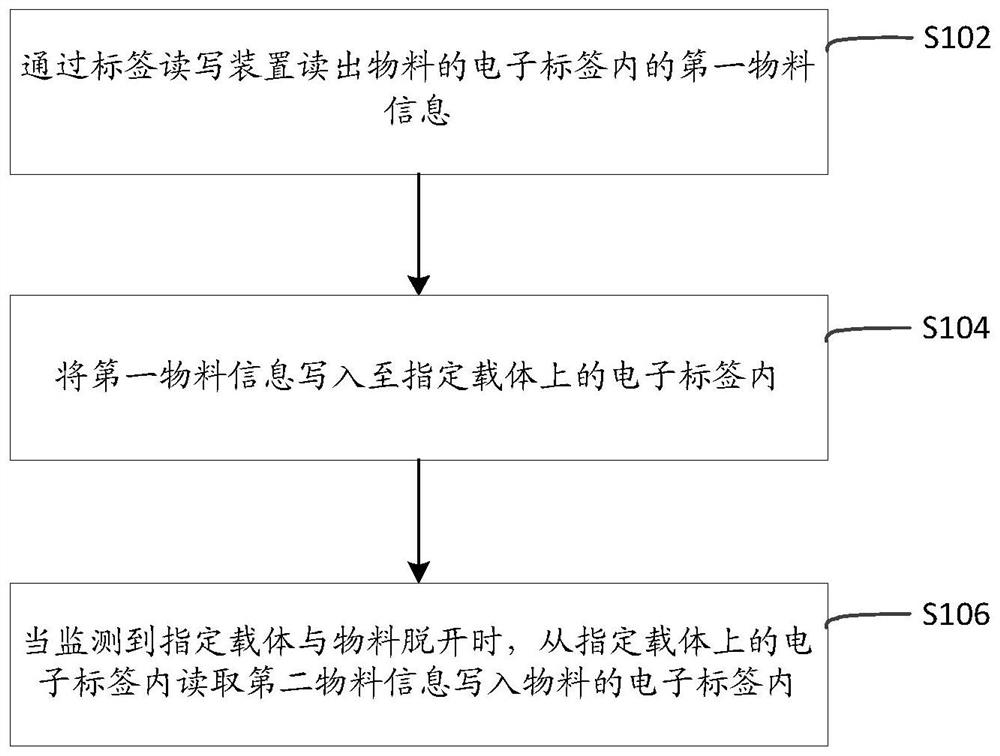

[0046] figure 1 It shows the flow chart of the method for updating material information provided by this embodiment. This method is applied to the production control equipment on the product production line. Electronic tags are attached to the materials on the product production line, and the material information of the materials is stored in the electronic tags. ,Such as figure 1 As shown, the method includes the following steps:

[0047] Step S102, read the first material information in the electronic tag of the material through the tag reading and writing device.

[0048]Specifically, the first material information in the electronic label of the material may include a material number corresponding to the process procedure. The corresponding relationship between the process program and the material number is pre-stored in the memory; each process program can correspond to multiple material numbers; the material number is the material number of the raw material. Obtain the...

Embodiment 2

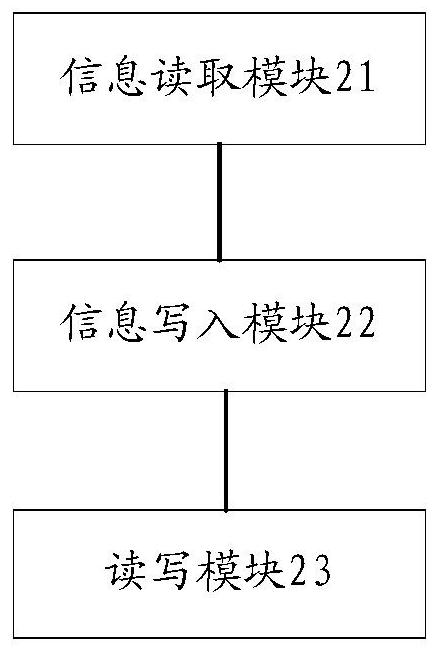

[0069] Corresponding to the methods provided in the above method embodiments, this embodiment provides a device for updating material information. The device is applied to production control equipment on the product production line, and electronic labels are attached to the materials on the product production line. The material information of the material is stored in the tag, such as figure 2 As shown, the device includes:

[0070] The information reading module 21 is used to read the first material information in the electronic tag of the material through the tag reading and writing device;

[0071] The information writing module 22 is used to write the first material information into the electronic tag on the specified carrier; the specified carrier and the material remain bound in at least one processing procedure;

[0072] The read-write module 23 is used to read the second material information from the electronic tag on the designated carrier and write it into the elec...

Embodiment 3

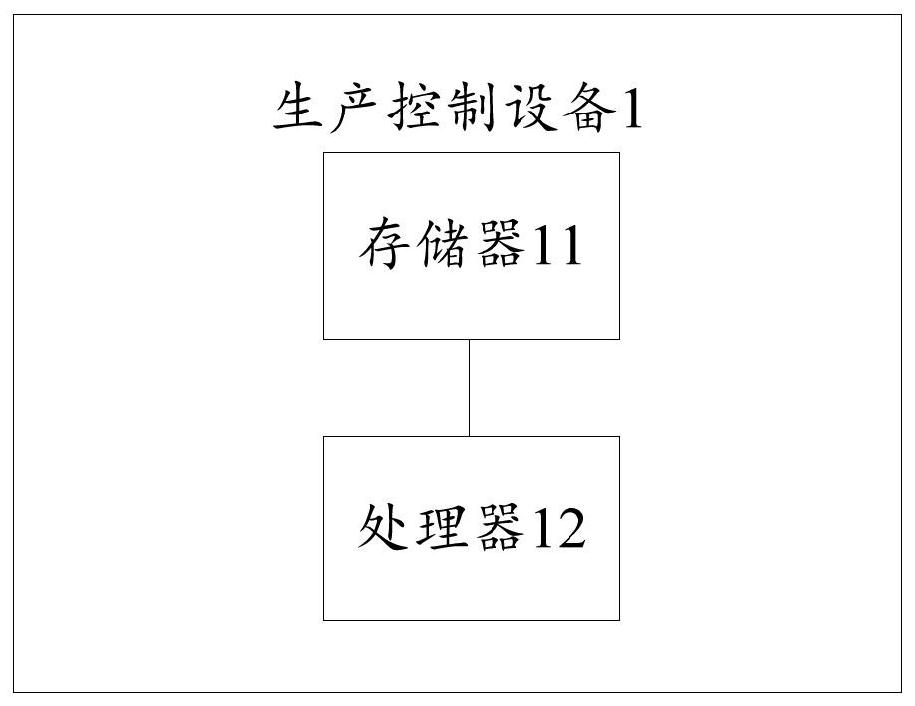

[0077] An embodiment of the present invention provides a production control device, such as image 3 As shown, the production control equipment for material update includes a memory 11 and a processor 12. The memory 11 can be used to store software programs and modules, such as the program instructions / modules corresponding to the material information updating device in the embodiment of the present invention, and the processor 12 By running the software programs and modules stored in the memory 11, various corresponding functional applications and data processing are executed, such as the material update method provided by the embodiment of the present invention. The memory 11 can mainly include a program storage area and a data storage area, wherein the program storage area can store an operating system, at least one function-required application program (such as the material updating device in the embodiment of the present invention) and the like; Display the data created b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com