Low-temperature and vacuum walnut kernel frying device

A technology of low-temperature vacuum frying and vacuum fryer, which is applied in the direction of oil/fat baking, etc. It can solve the problems of unsatisfactory comfort and crispy taste, destruction of nutrients, deep color, etc., and achieve saving oil consumption for frying, Improve the number of cycles and lighten the color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

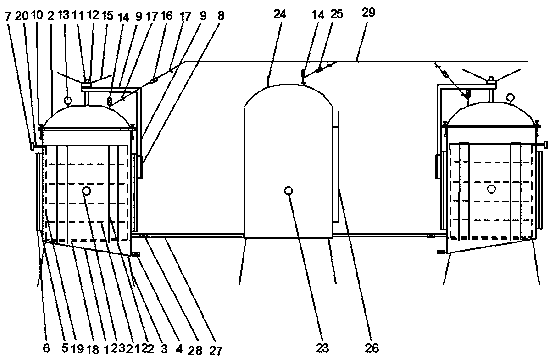

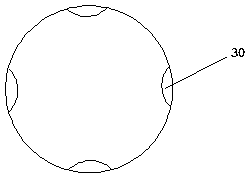

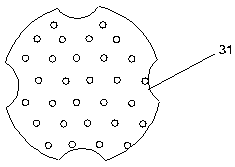

[0017] Such as figure 1 Shown, walnut kernel low-temperature vacuum frying device of the present invention is made of two identical vacuum fryers and a vacuum pot. The vacuum fryer has a structure of a cylinder, an inclined bottom 1, and a head cover 2. The bottom of the vacuum fryer is set as an inclined bottom to facilitate automatic cleaning of the oil residue produced in the fried walnut kernels. The bottom of the inclined bottom 1 is supported by a bracket 3 , and the bottom side of the inclined bottom 1 is provided with a slag discharge port and a valve 4 . The outer circumference of the cylinder is provided with a heating layer 5 and an insulating layer 6 in sequence, a vibrating motor 7 is provided on one side of the upper part of the cylinder, and a support ring 8 and an inverted L-shaped opening device for the head cover are provided on the other side opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com