Separation sieve for water conservancy construction slurry conveying device

A technology of construction mud and conveying device, applied in the field of separation screen, can solve the problem of easy jamming of impurities in the chute, and achieve the effect of reducing the probability of being unusable and avoiding the unusable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

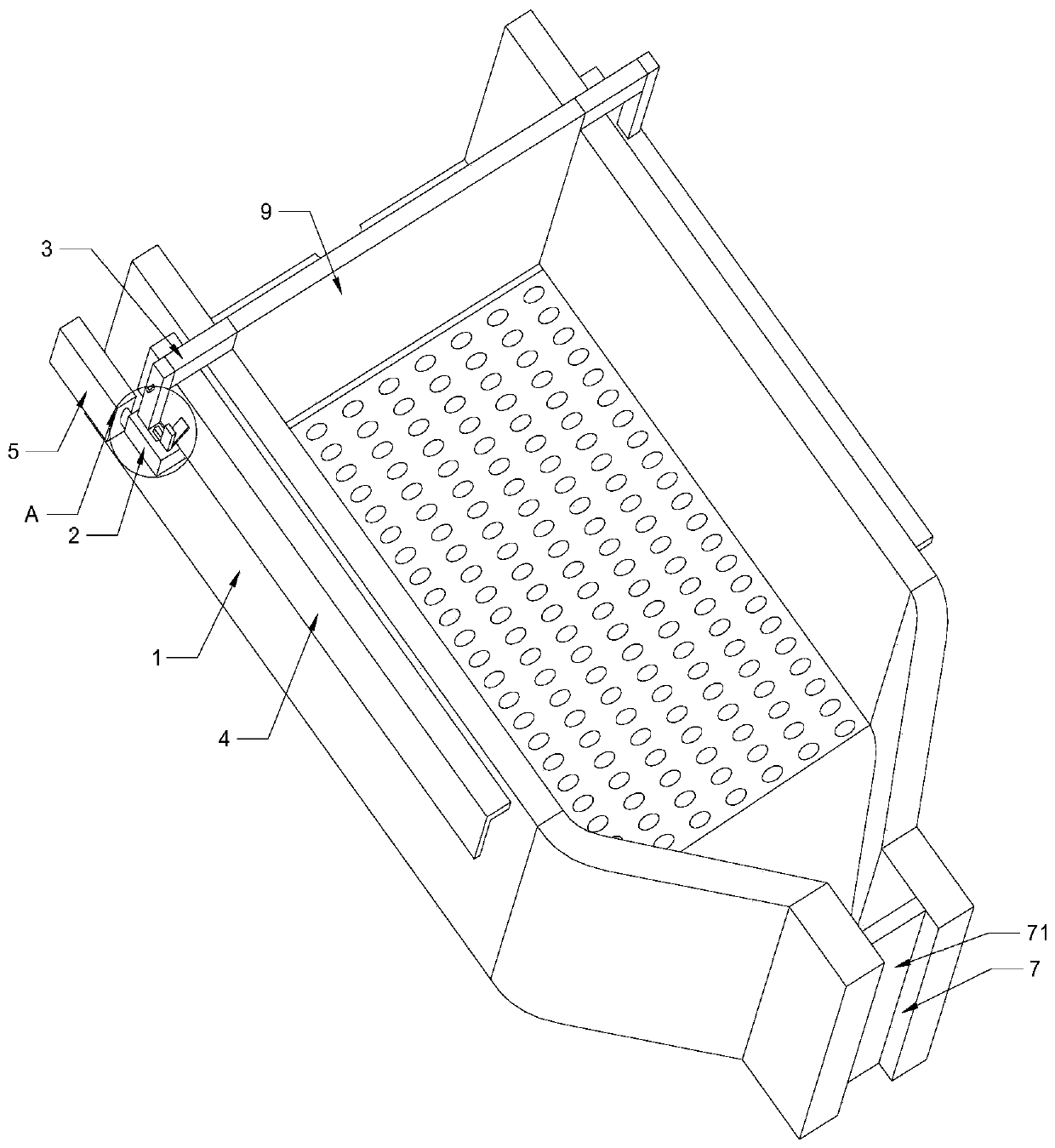

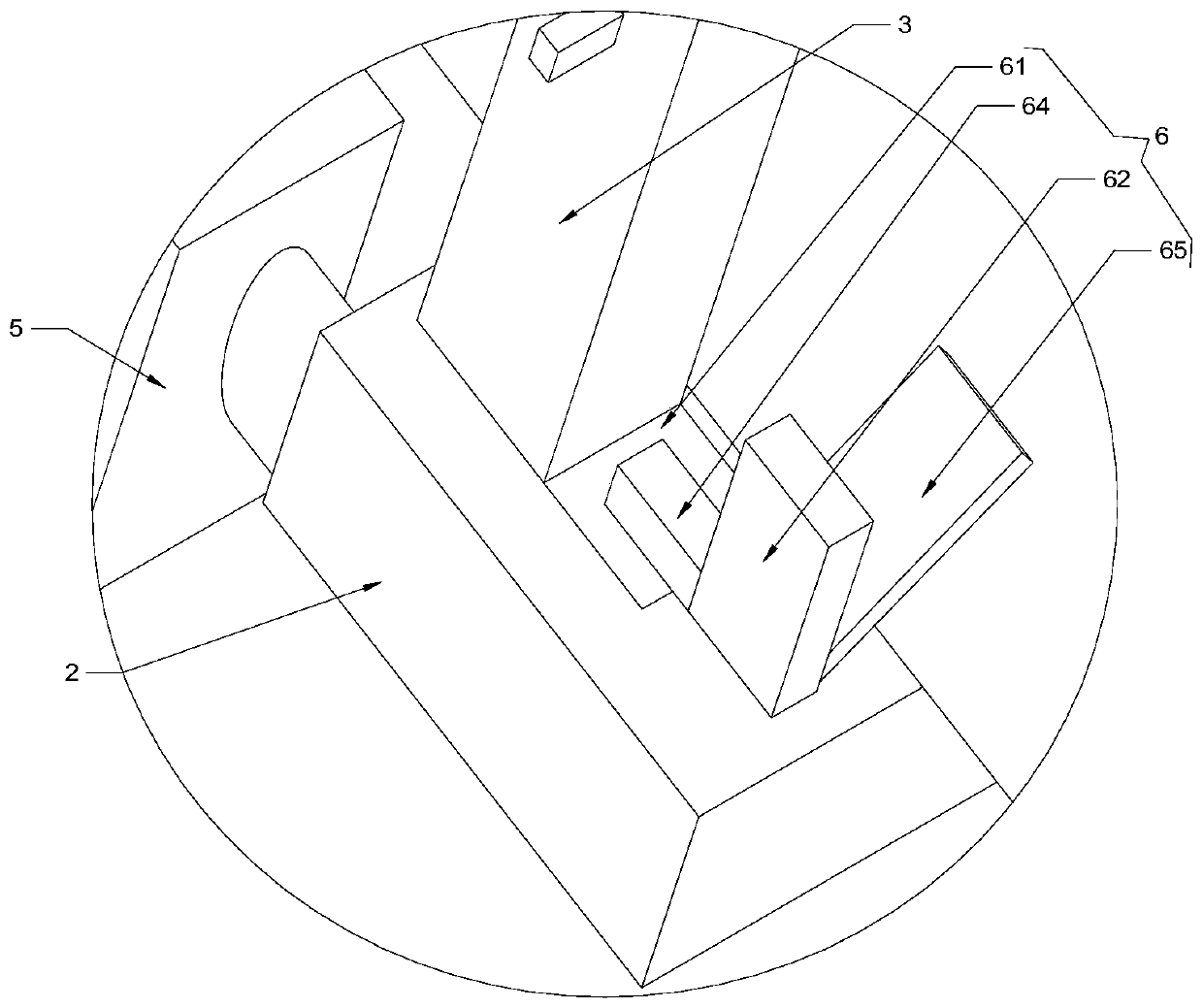

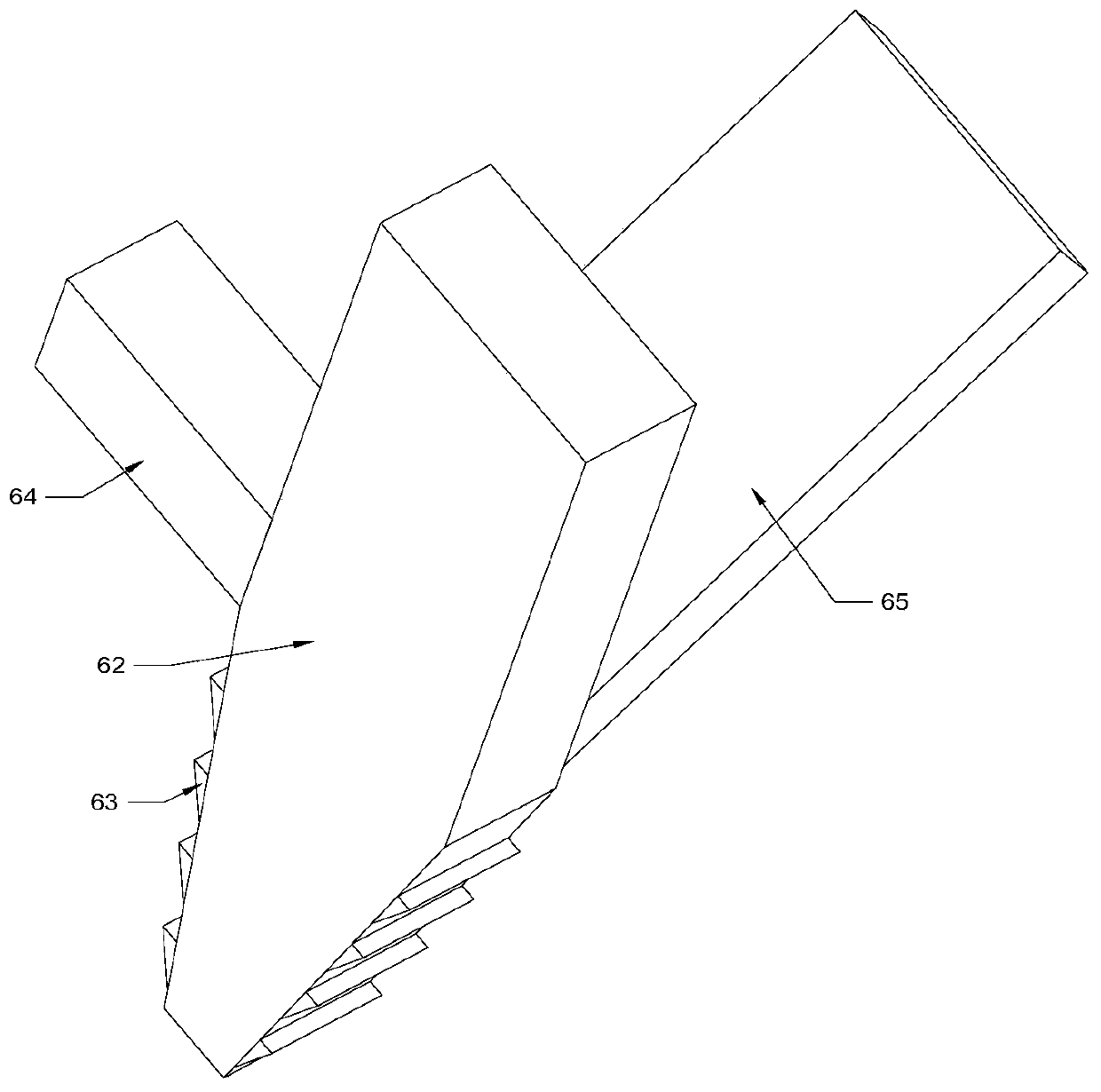

[0020] like Figure 1 to Figure 3 As shown, the present invention proposes a separation sieve for a hydraulic construction mud delivery device, comprising: a sieve body 1, where the high end of the sieve body 1 is located higher than the low end of the sieve body 1, and the high end of the sieve body 1 is used for inputting Separation of materials; two sliders 2, the outer walls of both sides of the sieve body 1 are recessed to form two chutes, and a slider 2 is installed in each chute, and the slider 2 is used to move between the high end of the sieve body 1 and the low end of the sieve body 1 Move; two covers 4, two covers 4 are installed on the outer walls on both sides of the screen body 1, each cover 4 is used to cover the joint between the slider 2 and the chute; two sliding rods 3, each slider 2 are connected to one end of a sliding rod 3; cleaning brush 9, the other end of each sliding rod 3 is fixed to the cleaning brush 9, the cleaning brush 9 is located in the sieve...

Embodiment 2

[0026] The difference between this embodiment and embodiment 1 is: on the basis of embodiment 1, the structure of the sieve body 1 is changed, and other structures remain unchanged.

[0027] like figure 1 , Figure 4 as well as Figure 5 As shown, the screen body 1 is equipped with an opening and closing assembly 7, and the opening and closing assembly 7 is used to open and close the bottom of the screen body 1. After the dumper of the transfer vehicle is filled with granular stones, another empty transfer vehicle needs to be replaced. If there are still granular stones discharged from the sieve body 1 at this time, the entire work site will be messy. Therefore, it is necessary to install an opening and closing assembly 7 to avoid the above phenomenon. When the transfer vehicle is aligned with the bottom of the sieve body 1, the opening and closing assembly 7 opens the bottom of the sieve body 1; when the transfer vehicle is away from the bottom of the sieve body 1, the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com