Universal gear shaping mechanism

A gear-shaping, universal technology, applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problem of single function of the universal gear-shaping mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

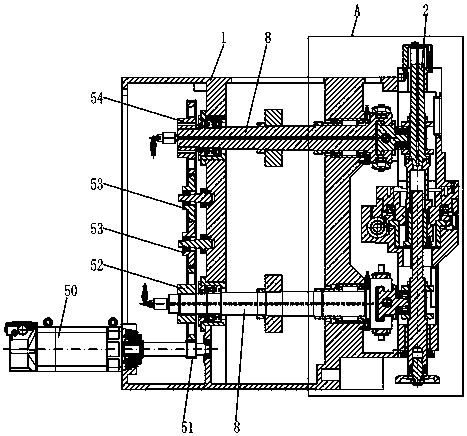

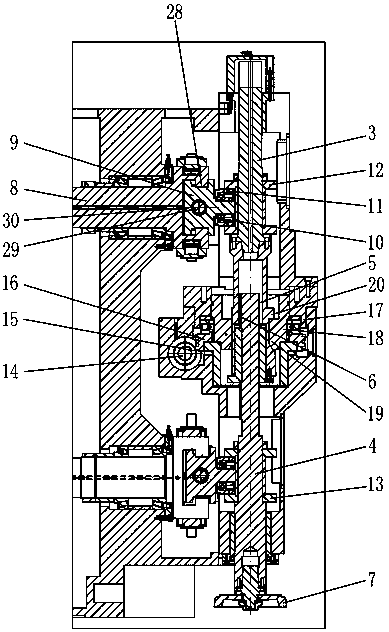

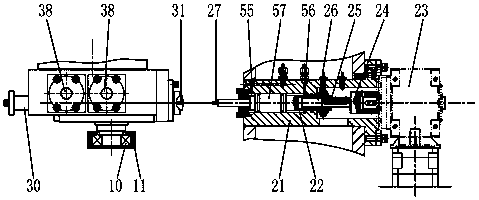

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0025] see Figure 1 to Figure 8 , the present invention provides a universal gear shaping mechanism, which includes a casing 1 and a main shaft 2 arranged in the casing 1. The main shaft 2 includes an upper shaft 3 and a lower shaft 4. The upper end of the lower shaft 4 is inserted on the upper The lower end of the shaft 3, and the two are connected by a spline flange mechanism. The spline flange mechanism includes a spline hole 5 arranged at the lower end of the upper shaft 3, a spline shaft 6 arranged at the upper end of the lower shaft 4, and the spline shaft 6 is inserted into the spline hole 5, and the two can move up and down relative to each other in the axial direction. There is a screw rotating device between the upper shaft 3 and the lower shaft 4, and the screw rotating device drives the upper shaft 3 and the lower shaft 4. Rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com