Gasifier combustor

A burner, gasifier technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of complex operation, difficult sealing problems, large investment costs, etc., to achieve pressure balance, ensure service life, guarantee The effect of ignition reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

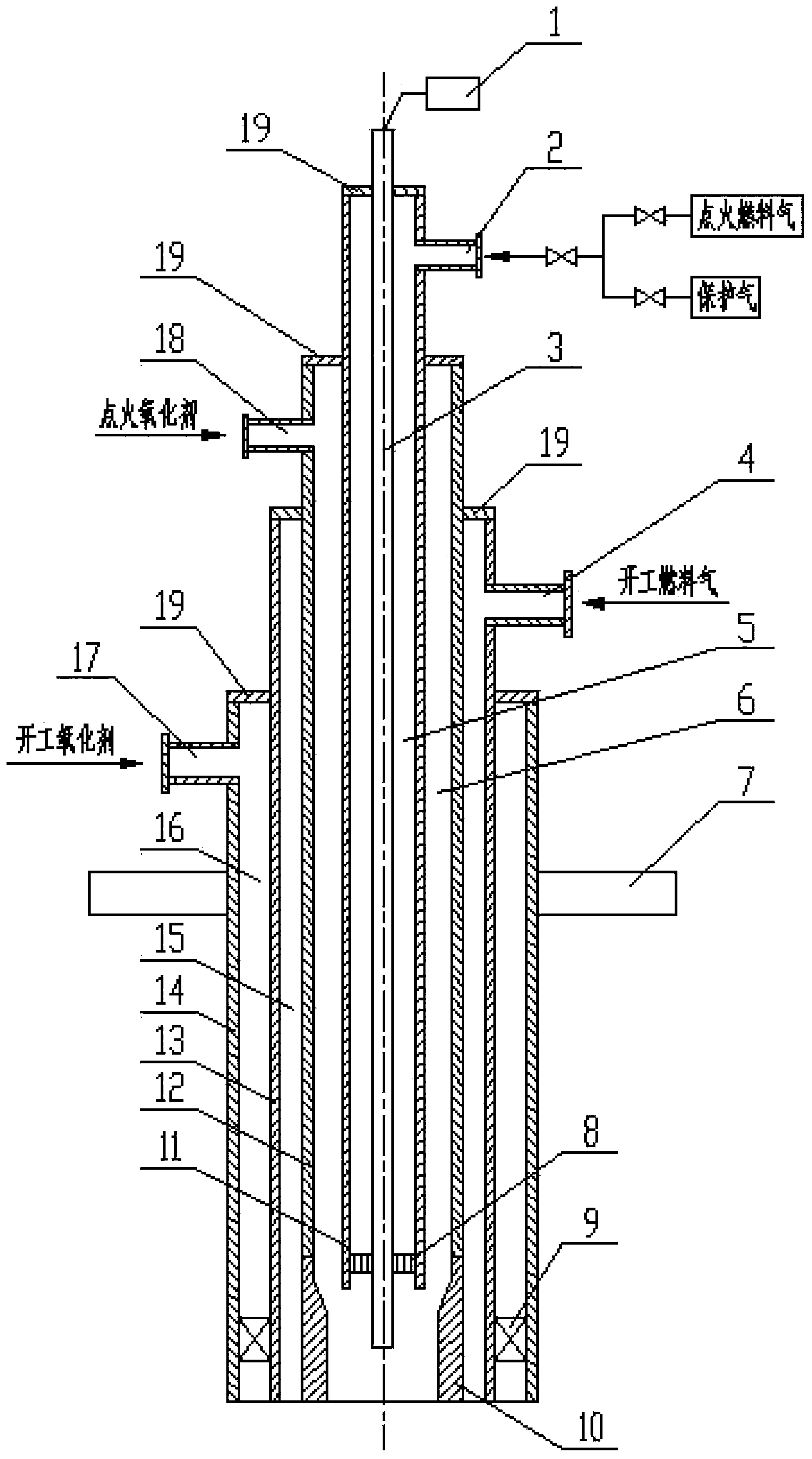

[0032] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0033] See figure 1 , The start-up preheating burner of the gasifier using combustible gas as fuel of the present invention includes the ignition rod 3, the central tube 11, the inner tube 12, the middle tube 13 and the outer tube 14 coaxially arranged from the inside to the outside, It constitutes the main structure of the preheating burner of the gasifier. And the burner is connected to the furnace body or process burner ( figure 1 Not shown) The sealed connection is fixed. The internal pipeline connection of the combustor is completed by welding the sealing cover plate 19, or a sealed flange connection structure can be used. Each part can not only be disassembled and repaired separately, but also will not affect other parts.

[0034] The ignition rod 3 and the central tube 11 constitute an ignition fuel gas channel 5, the ignition rod 3 is arranged in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com