A pvc pipe thread drawing device with internal and external double clamping functions

A PVC pipe and thread technology is applied in the field of PVC pipe thread drawing devices, which can solve the problems of inconsistent size specifications and insufficient thread length, and achieve the effects of increasing pressure, not easy relative sliding, and reducing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

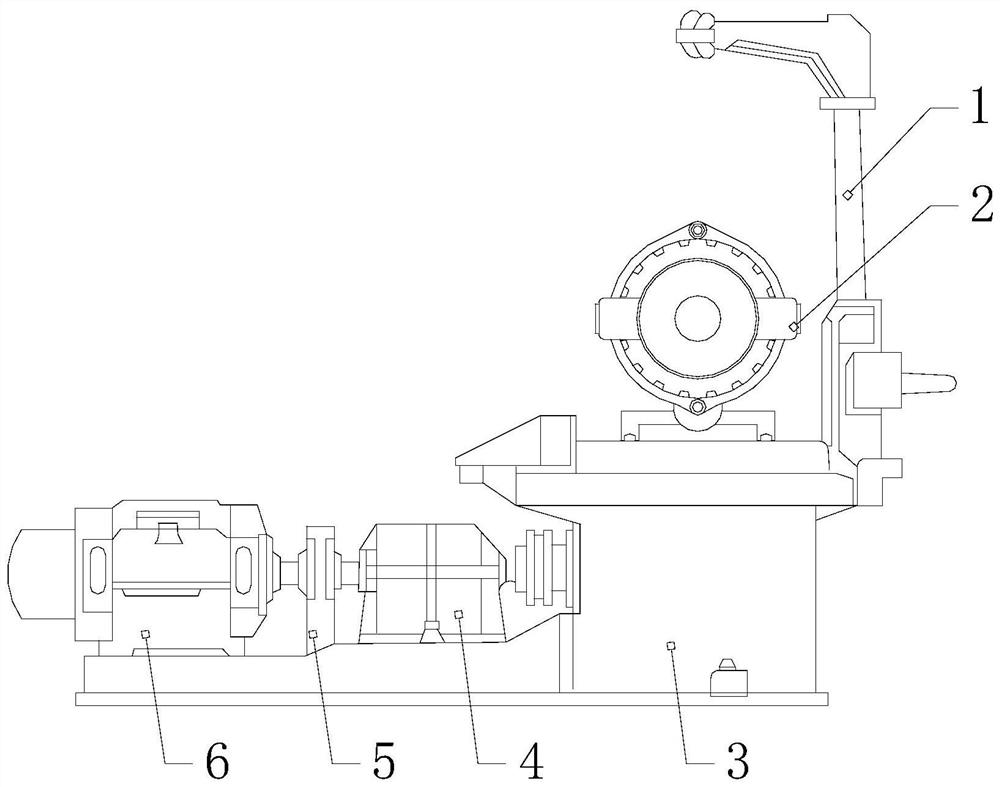

[0024] see Figure 1-Figure 7 , the present invention provides a PVC pipe thread drawing device with internal and external double clamping functions, its structure includes a cantilever crane 1, a clamping structure 2, a gear box 3, a reducer 4, a brake 5, a motor 6, the gear box 3 A clamping structure 2 is installed in the middle of the top surface, and a tap is also installed on the same axis as the clamping structure 2. A cantilever crane 1 is installed on one side of the gear box 3, and a cantilever crane 1 is installed on the side and bottom of the gear box 3 of the cantilever crane 1. The reducer 4 is mechanically connected to the motor 6 through the brake 5, and the motor 6 and the reducer 4 are on the same axis.

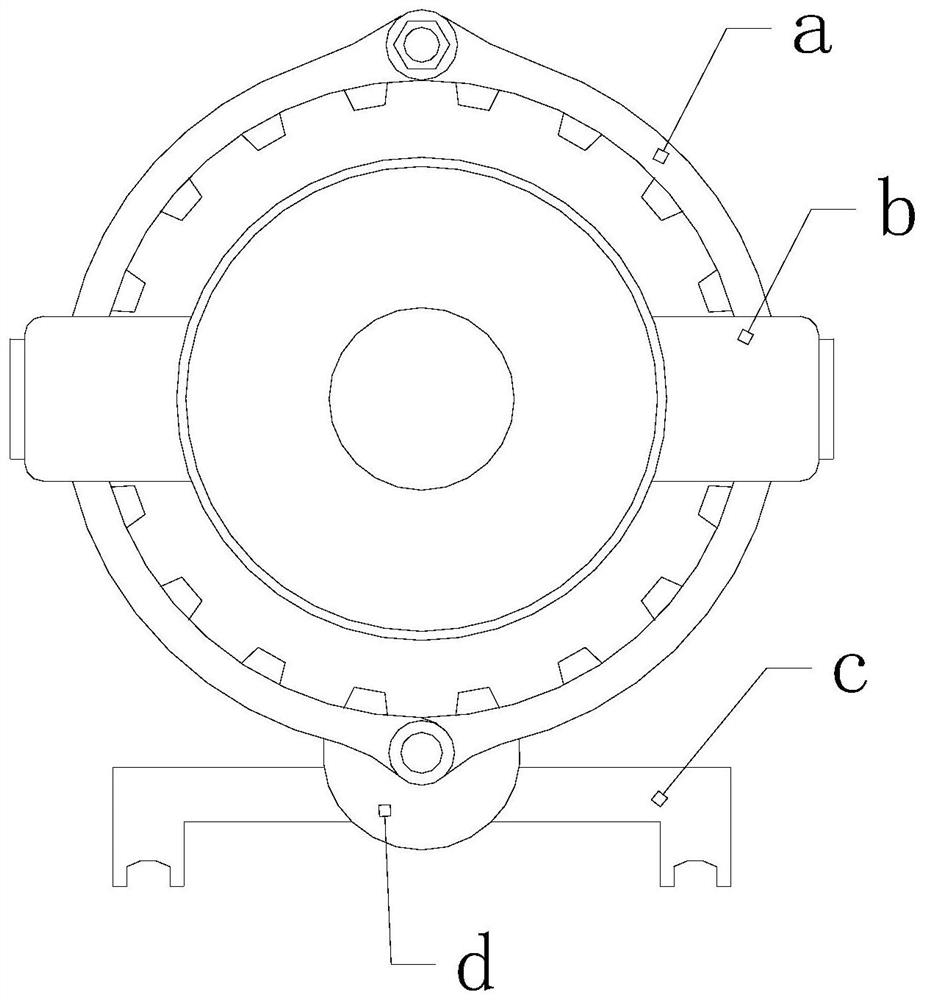

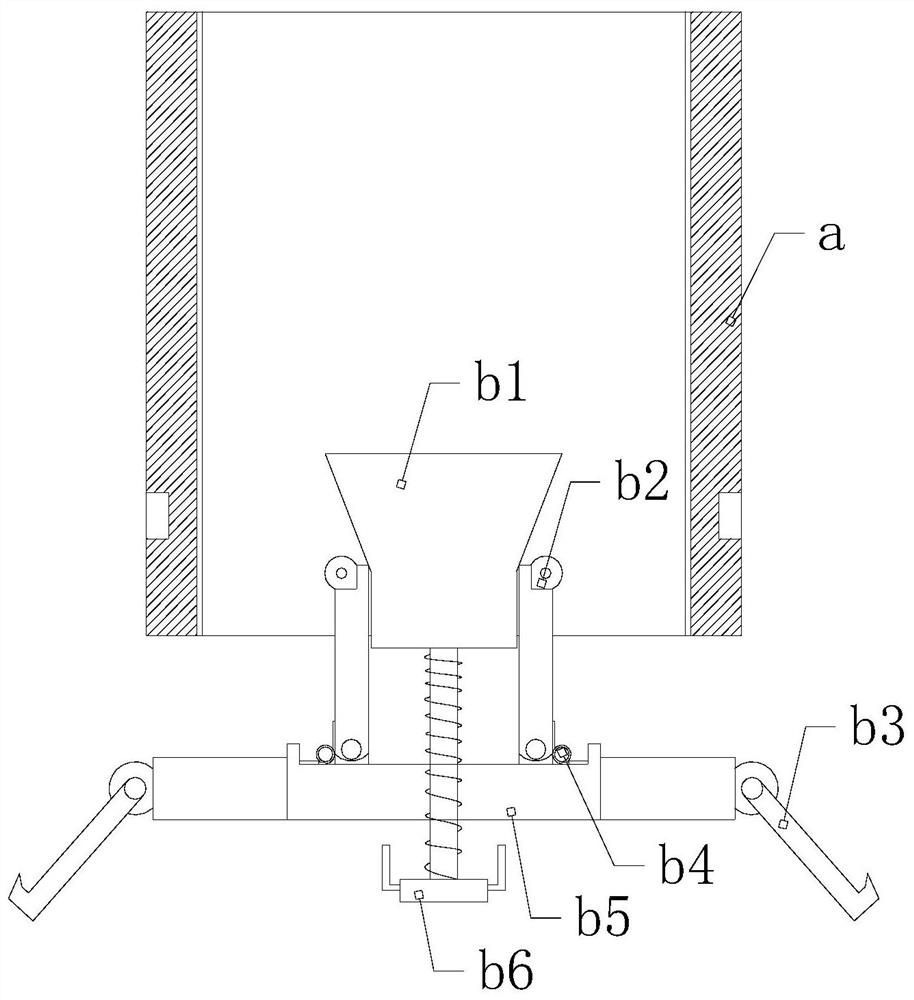

[0025] The clamping structure 2 is mainly composed of an outer jacket a, an outer expanded inner jacket b, a fixed base c, and a connecting sleeve d. The bottom of the outer jacket a is fixed on the top surface of the fixed base c through the connecting sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com