Carton conveying frame with transferring device

A technology for transfer devices and conveyor racks, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve problems such as insufficient automation, large manual labor, and no central transfer mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

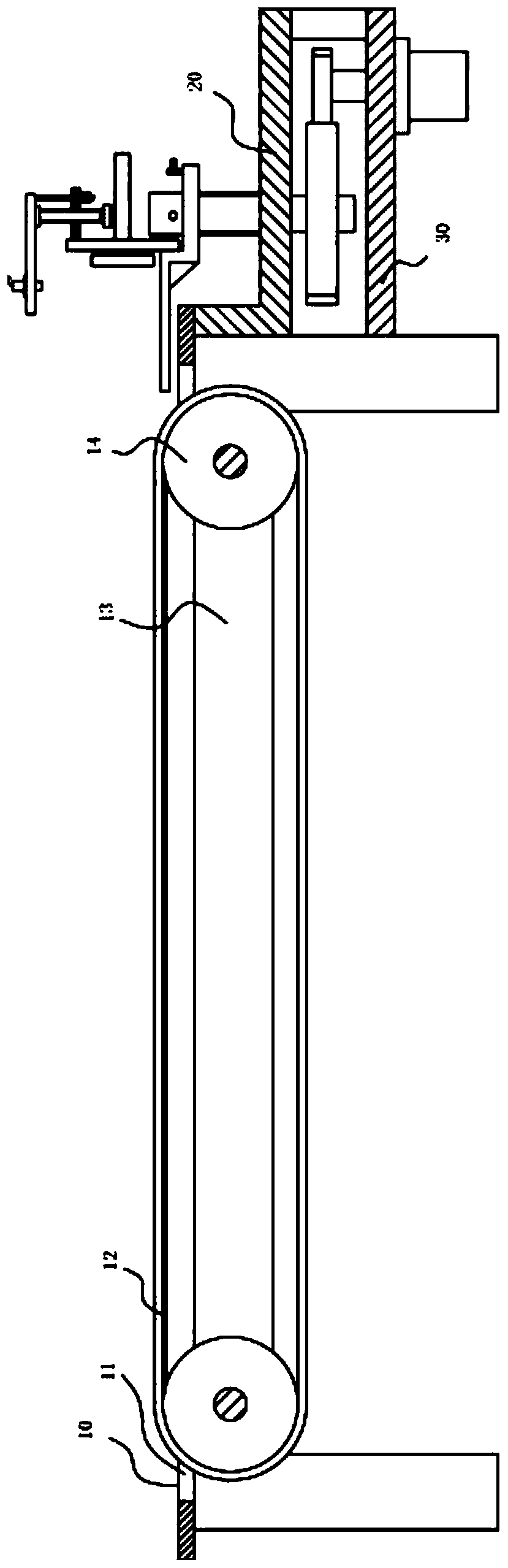

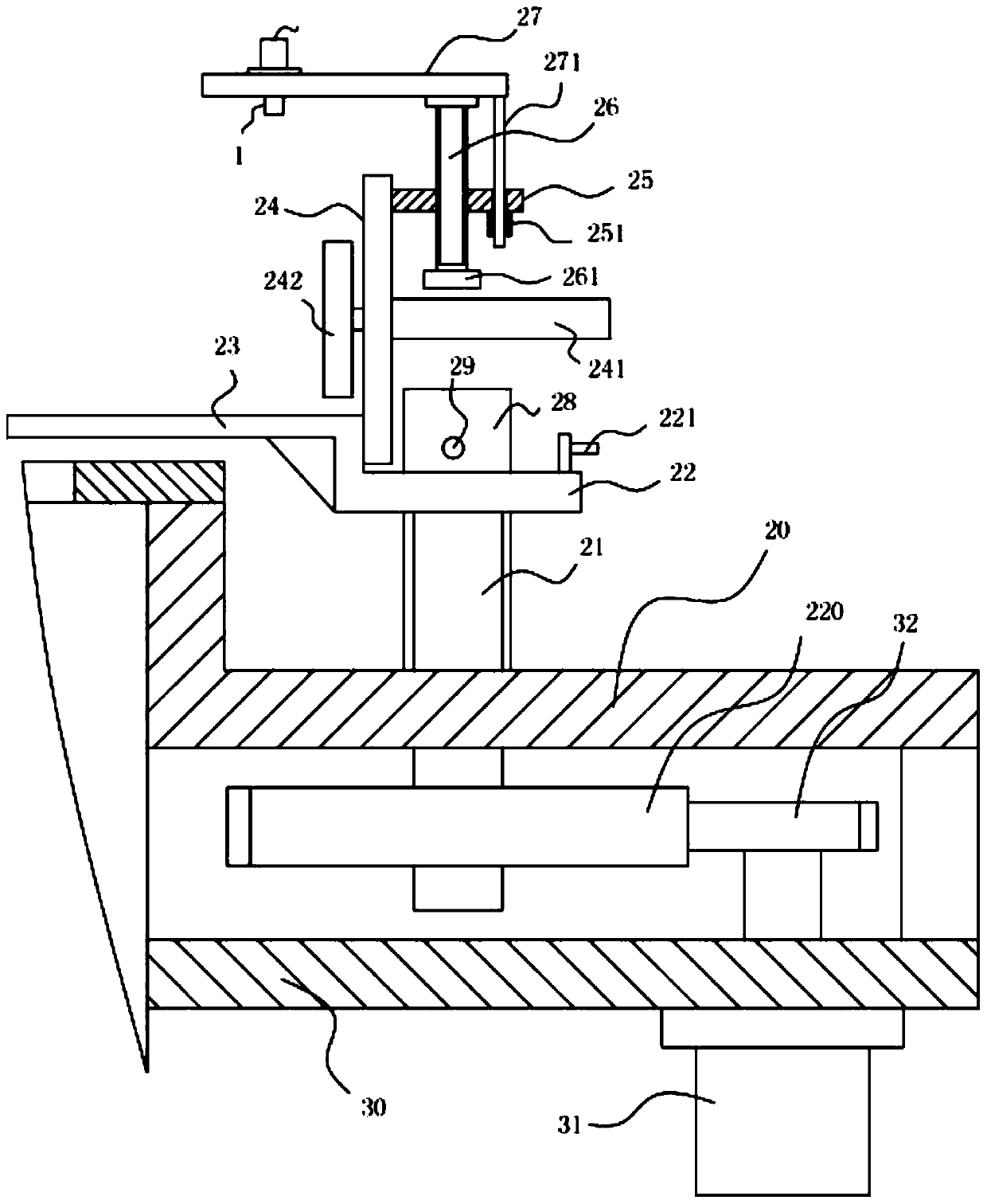

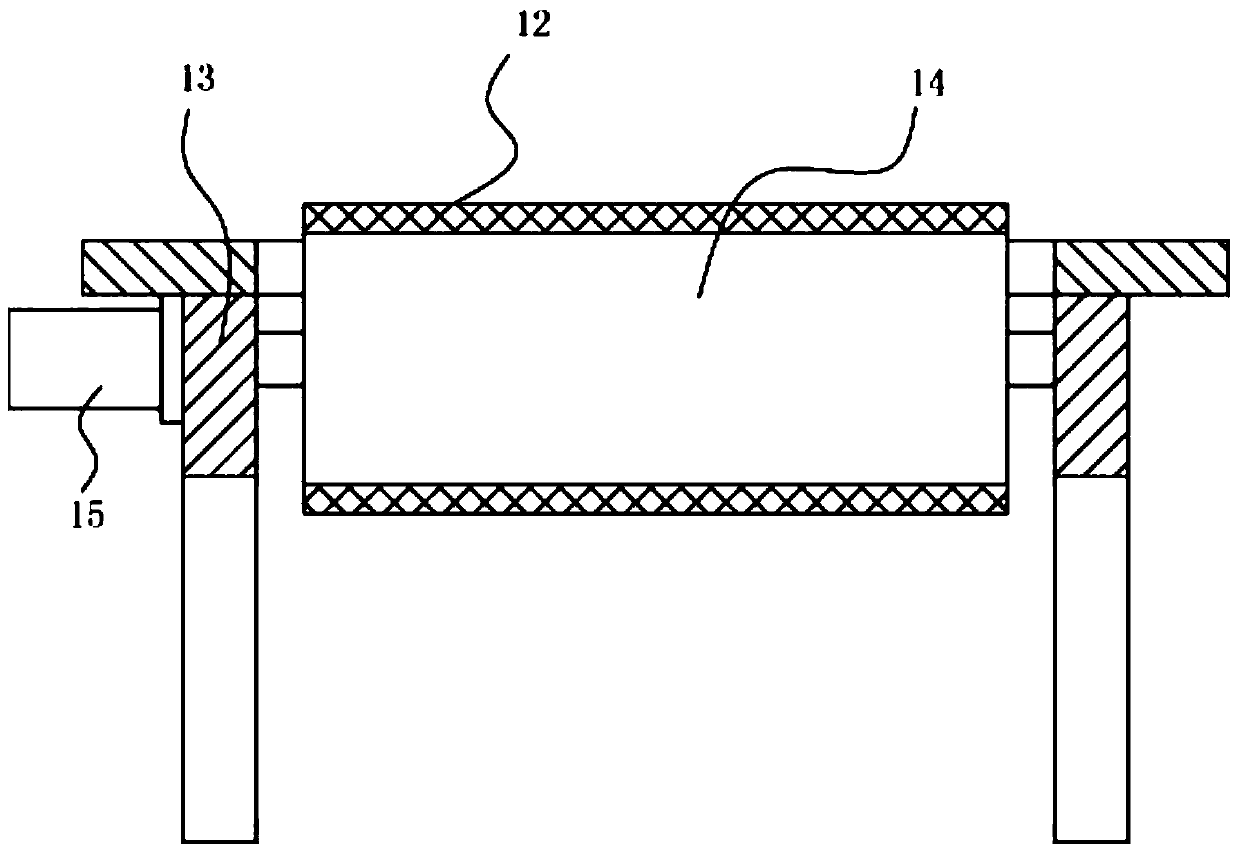

[0020] Example: see Figure 1 to Figure 3 As shown, a carton conveying rack with a transfer device includes a conveying rack 10. The middle of the top plate of the conveying rack 10 has a main conveying trough 11, the conveying belt 12 is in the conveying main trough 11, and the top plate of the conveying rack 10 An upper support frame 20 is fixed on the right bottom surface of the upper support frame 20. The middle of the top plate of the upper support frame 20 is hinged with a rotating main shaft 21 through a bearing. The top end of the rotating main shaft 21 extends from the top plate of the upper support frame 20 and is fixed with a rotating plate 22. The rotating plate 22 A bent splice plate 23 is formed at the left end of the bent splice plate 23, and the left part of the horizontal part of the bent splice plate 23 is above the right part of the top plate of the conveyor rack 10 and corresponds to the right end of the conveyor belt 12;

[0021] The bottom surface of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com