Assembled large-span ultra-high performance concrete (UHPC) box girder combined node and connection method thereof

A concrete box girder, ultra-high-performance technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of restricting the application and development of prefabricated bridges, high transportation costs of large prefabricated components, and unsatisfactory seismic performance at joints To achieve the effect of ensuring the stability of the project, shortening the construction time and excellent mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

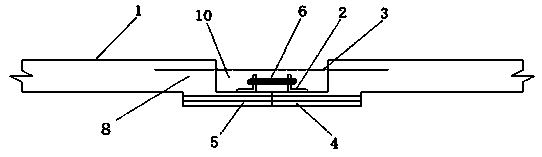

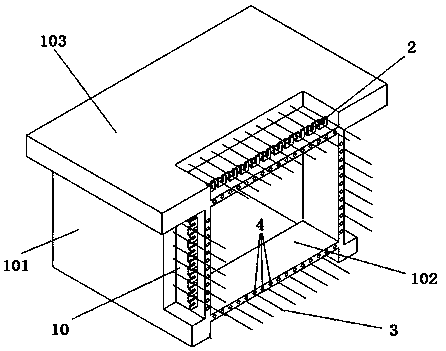

[0030] See attached figure 1 , attached figure 2 And attached Figure 4 , the assembled long-span concrete box girder combined node of the present invention includes a box girder main body 1 and a prestressed tie rod 5; the butt joint of the box girder main body 1 is set as a zigzag joint 8, and the second butt joint surface 802 of the zigzag joint 8 is pre-embedded The outstretched steel bar 3, the first butt joint surface 801 of the zigzag joint 8 to the pre-embedded prestressed tie rod through hole 4 behind the zigzag joint 8, the main body of the box girder 1 passes through the pre-embedded outstretched steel bar 3, the prestressed tie rod through hole 4 and its The corresponding prestressed tie rods 5 are connected, and the joints are filled with concrete grouting material.

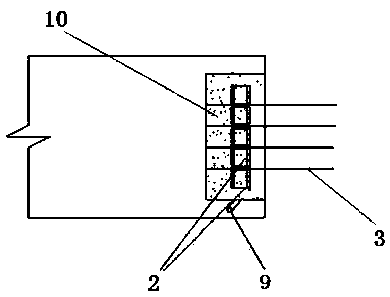

[0031] As a further improvement, the present invention also includes a steel anchor block connection system, (see attached Figure 5 ) includes an L-shaped steel anchor block 2 and a pre-tighteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com