Support combination

A pair of support sleeve technology, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of long installation time, unstabilized vertical head nuts, and many brackets falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

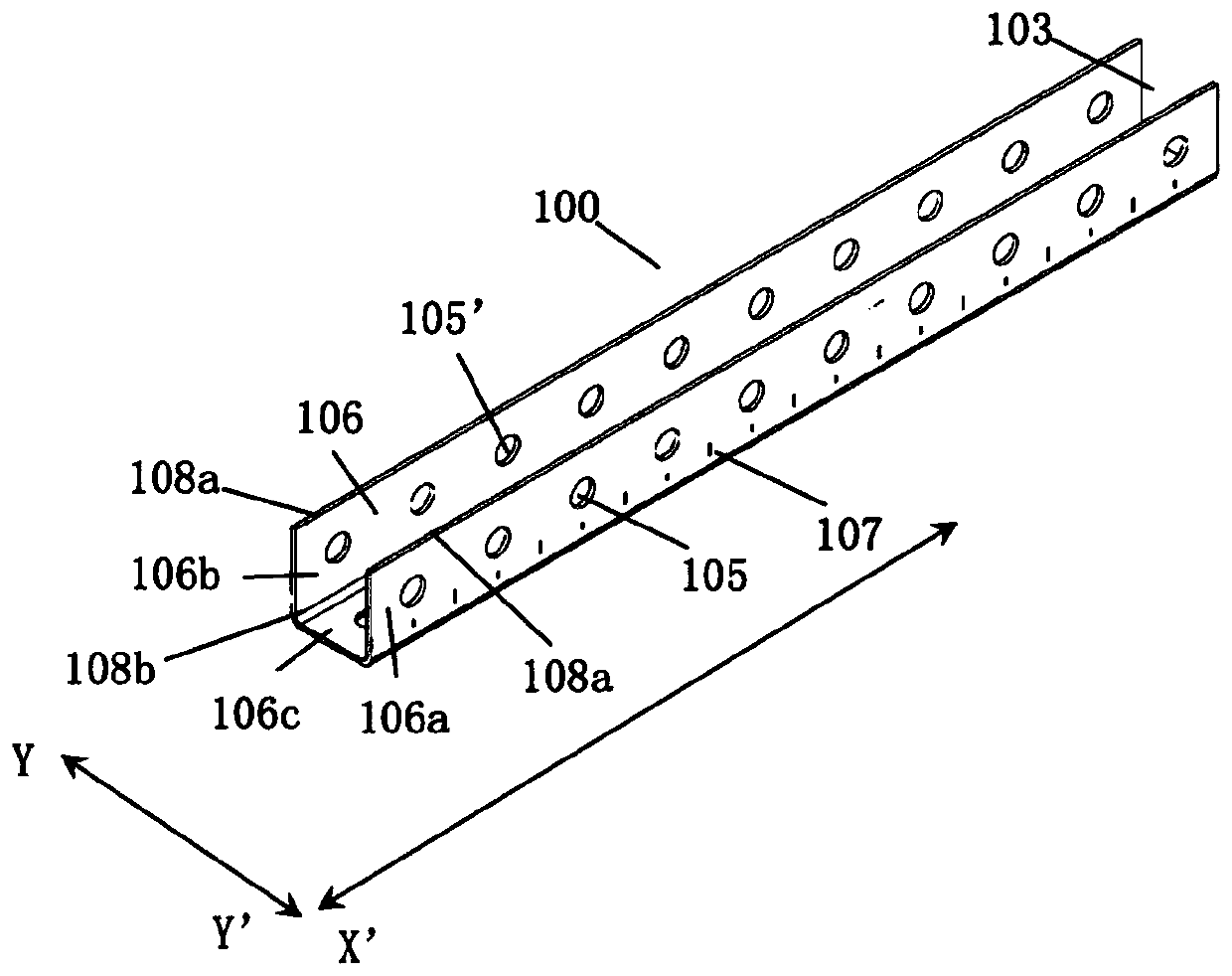

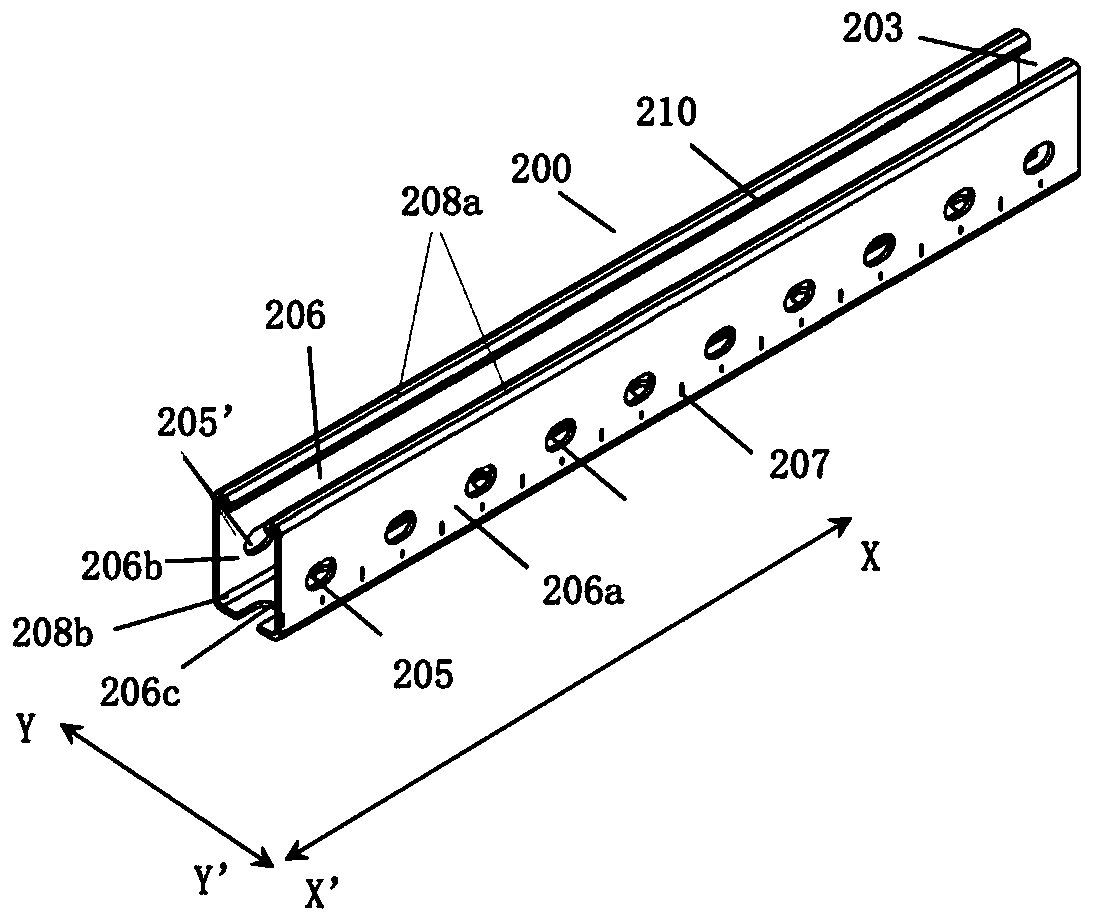

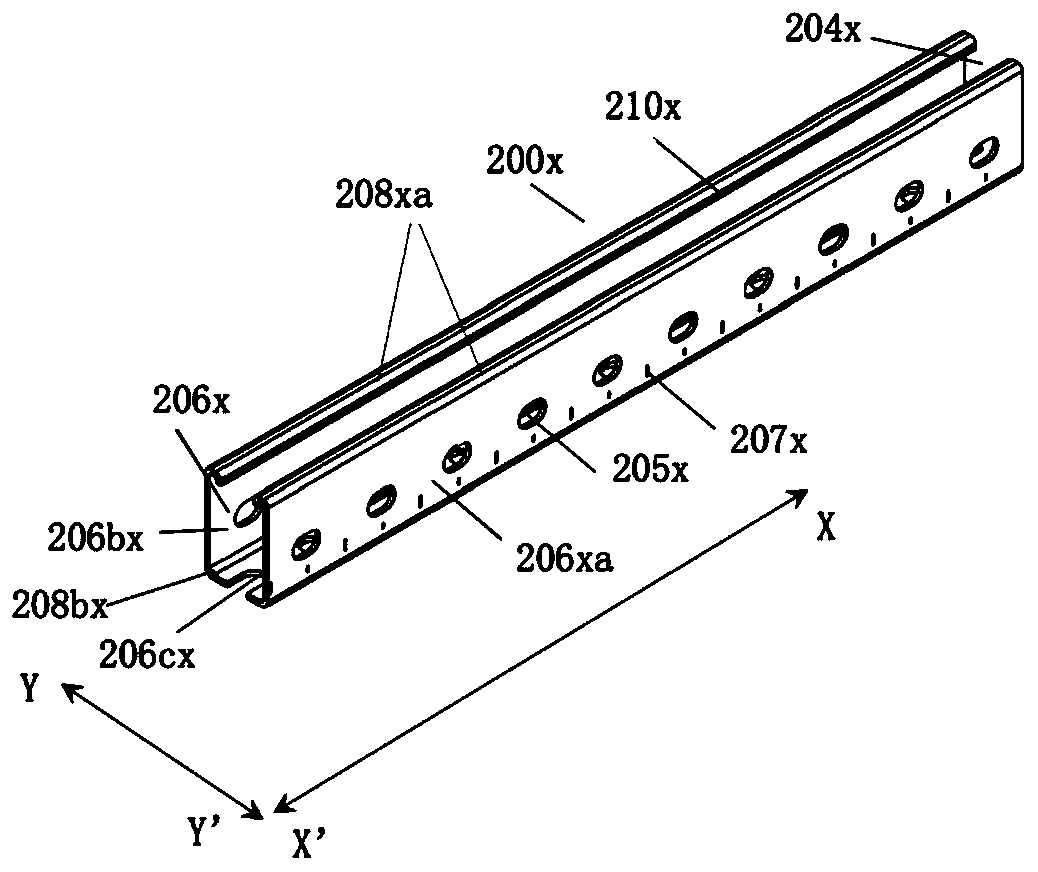

[0103] Embodiment 1 discloses a bracket combination, including a first guide rail (also referred to as a "vertical beam" in some embodiments) 100 and a second guide rail (also referred to as a "support beam" in some embodiments) ) 200, the first guide rail 100 adopts a U-shaped groove structure, including a first guide rail wall 106 and a first notch 103, and at least a pair of first installation holes 105 are provided on the first guide rail wall 106. The second guide rail 200 adopts a U-shaped groove structure, including a second guide rail wall 206 and a second notch 203, and the second guide rail wall 206 is provided with at least one pair of second mounting holes (in some embodiments, it may also be referred to as "support beam screw holes") 205 . In this embodiment, the width of the first notch 103 (ie figure 1 , the opening size of the first notch 103 along the Y-Y' direction) is greater than the width of the second rail (ie figure 1 , the size of the second guide rai...

Embodiment 2

[0132] See Figure 4. The difference between this embodiment and Embodiment 1 is that the bracket assembly further includes a base 400 . The base 400 includes at least one base fixing part 402 and at least one base rail connecting part 404 . The base 400 may be fixed on a surface (eg, wall, ground, steel structure) by the at least one base fixing member 402 . The base 400 can be fixedly connected to the first guide rail 100 through the at least one base guide rail connector 404 .

[0133] In some embodiments, the base rail connector 404 includes a plurality of base side walls 406, the base side walls 406 are provided with base mounting holes 405, and the plurality of base side walls 406 are connected to the first rail wall. 106 is fixedly connected by penetrating bolts 101 passing through the base installation hole 405 and the first installation hole 105 .

[0134] In some embodiments, the base fixture 402 employs one or more flat plates 402 a , 402 b vertically connected to...

Embodiment 3

[0141]The difference between this example and Example 1 is that the bracket combination further includes a fall prevention connector (also referred to as a "right-angle connector" in some embodiments) 500, including a first guide rail connection area 500a and a second guide rail Connection area 500b. The first guide rail connection area 500 a can be placed in the first notch 103 and fixedly connected with the first guide rail 100 . The second guide rail connection area 500 b can be placed in the second notch 203 and fixedly connected with the second guide rail 200 .

[0142] In some embodiments, the anti-fall connector 500 includes two parallel first anti-fall fixing plate 501 , second anti-fall fixing plate 502 and anti-fall connecting plate 503 . The anti-fall connecting plate 503 is vertically arranged between the first anti-fall fixing plate 501 and the second anti-fall fixing plate 502, and connects the first anti-fall fixing plate 501 and the second anti-fall fixing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com