Mini-tiller shifting speed changing mechanism and mini-tiller comprising same

A speed change mechanism and micro-tiller technology, applied in the field of micro-tillers, can solve the problems of inability to operate normally for a long time, reduced power transmission reliability, and inability to meet agricultural production, etc., and achieve strong impact resistance, flexible speed control, and power. Low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

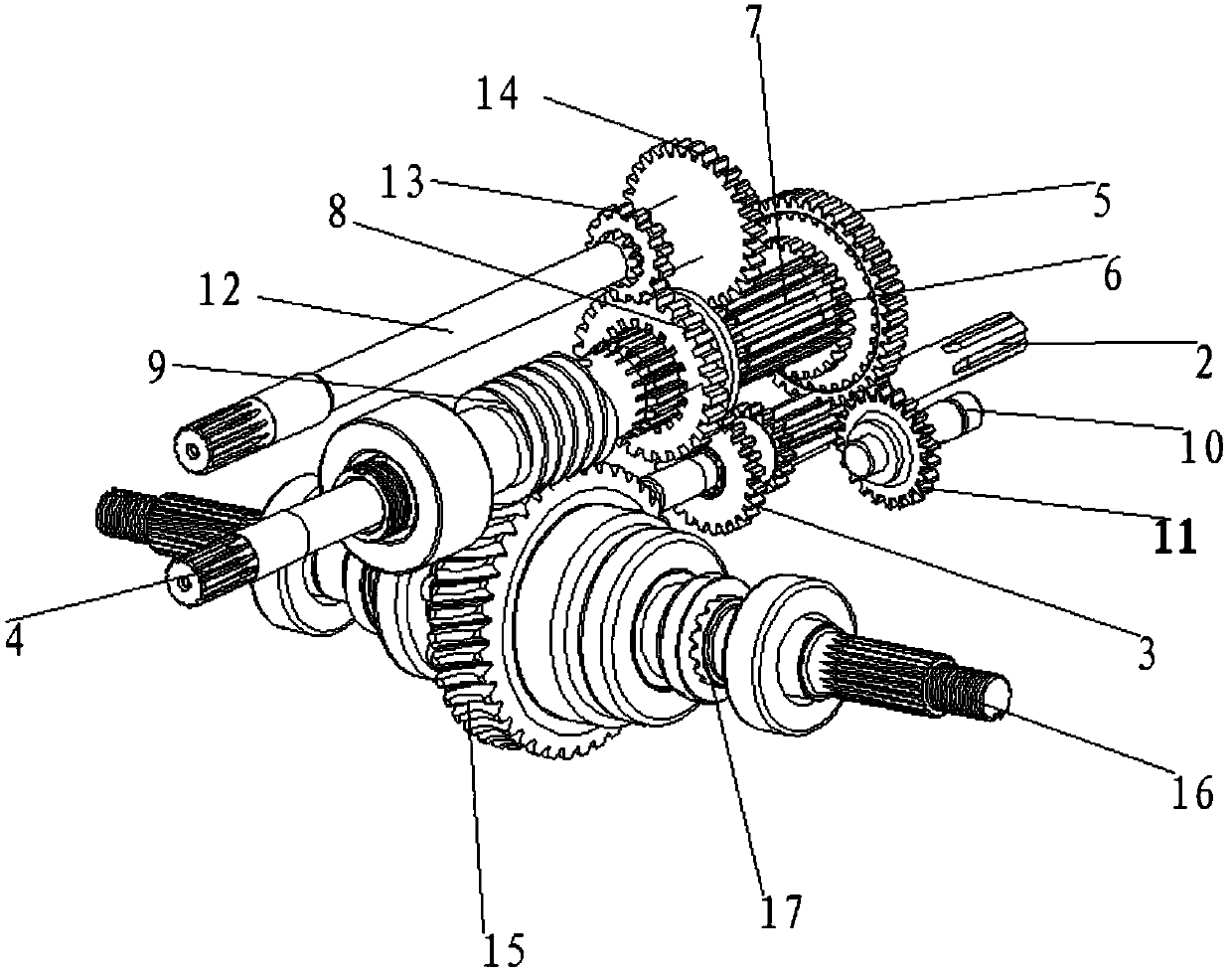

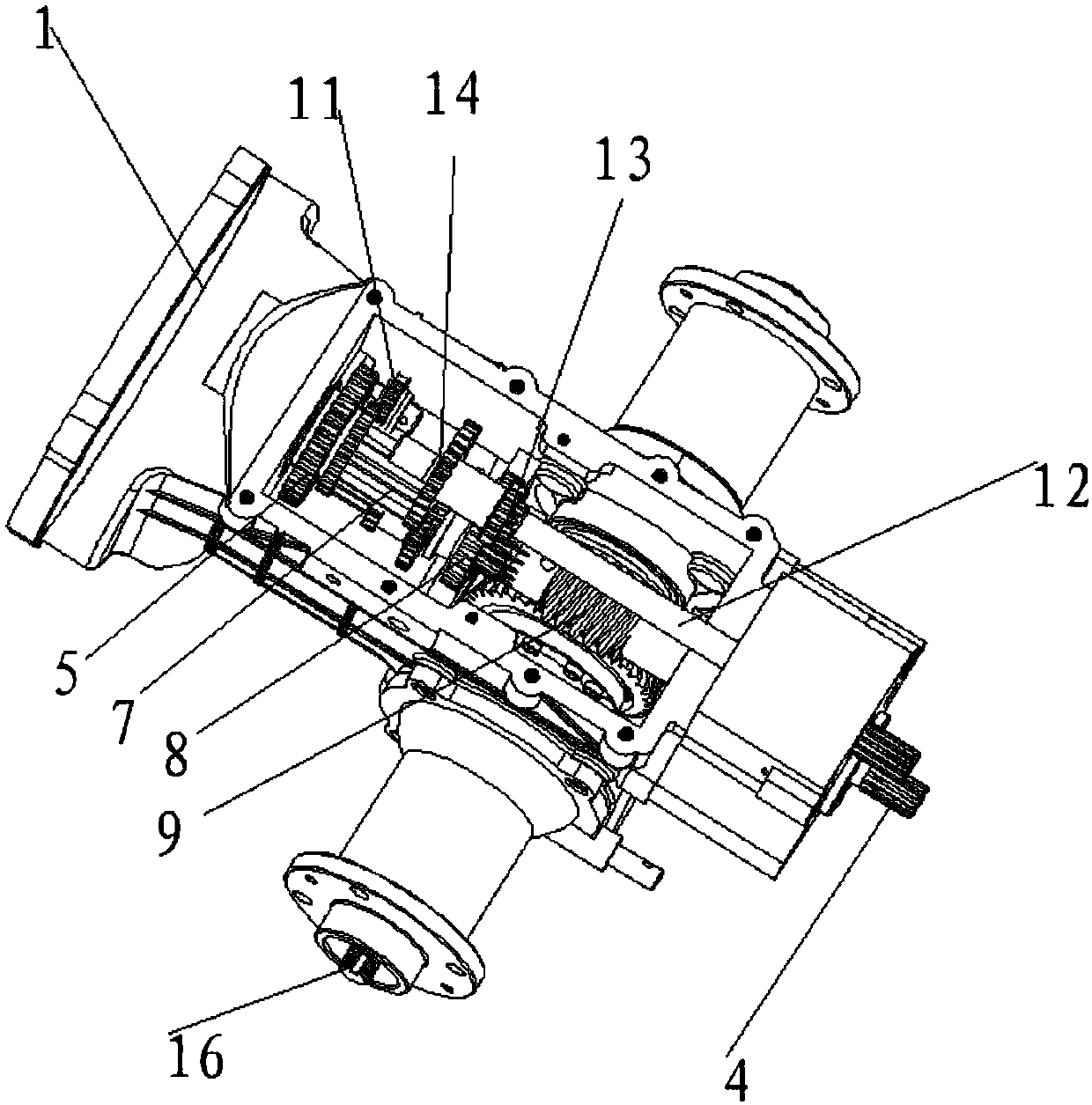

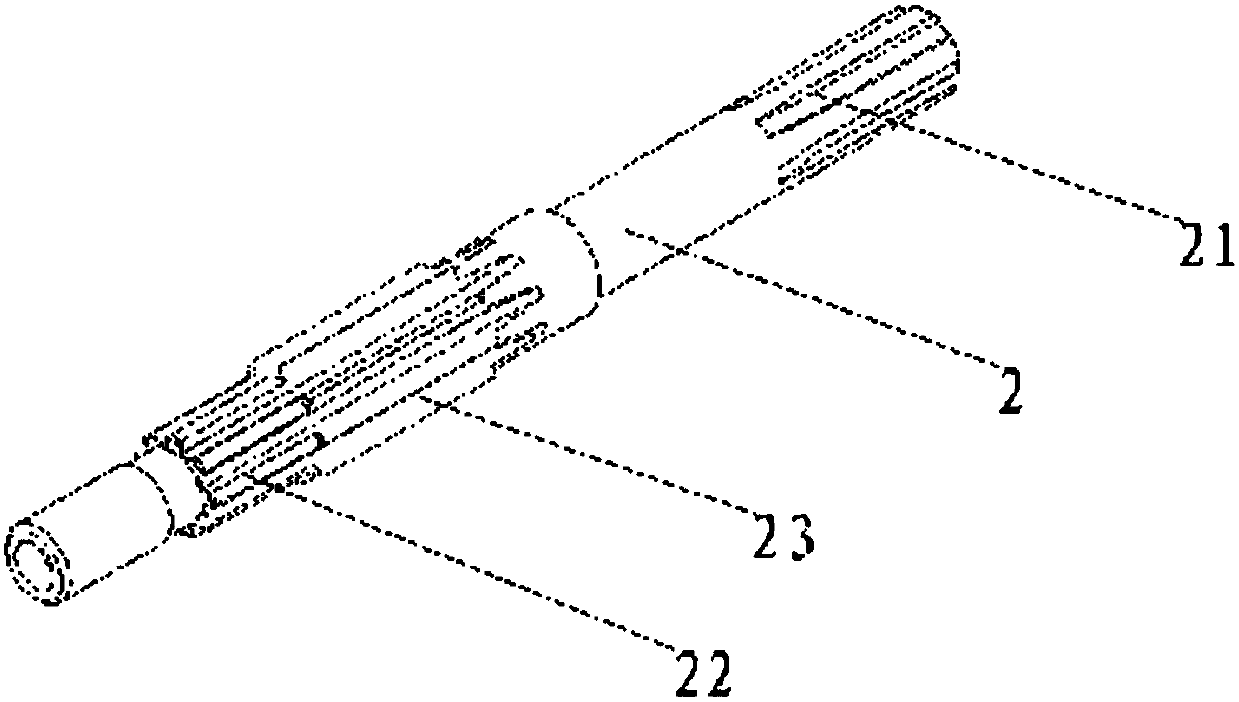

[0022] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of structural assembly of the present invention, image 3 It is a schematic diagram of the main shaft structure, as shown in the figure: the gear shifting mechanism of the tiller in this embodiment includes a casing 1, a main shaft assembly, a gear shifting assembly and a reverse gear assembly. Of course, the casing in this embodiment is also provided with There is a shift fork, and it is provided with a driving device for driving the shift fork, which is used to adjust the positions of the worm meshing teeth, countershaft shift teeth and shift double teeth, which belongs to the prior art and will not be repeated here. repeat;

[0023] The main shaft assembly includes a main shaft double tooth 3 for fixing the power input main shaft 2 and the outer casing to the main shaft 2;

[0024] The shifting transmission assembly includes a layshaft 4 and synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com