A Multi-working Mode Aircraft Spare Compass Calibrator

A working mode, calibrator technology, used in compass, instrument, surveying and navigation, etc., can solve the problems of long startup and calibration time, large damage to calibration equipment, high frequency of repeated operation, and achieve fast detection speed and calibration time. Short, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The multi-working mode aircraft standby compass calibrator provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

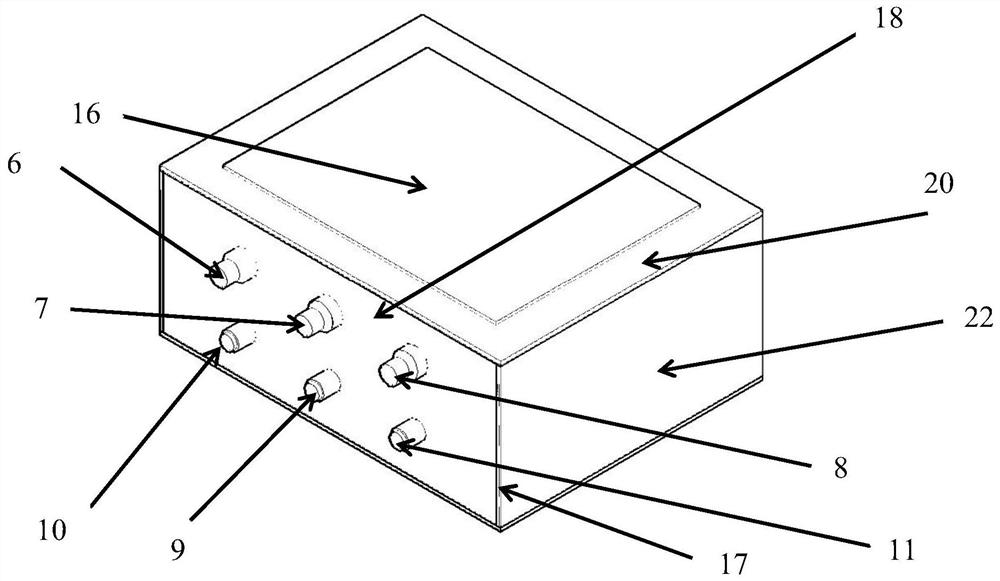

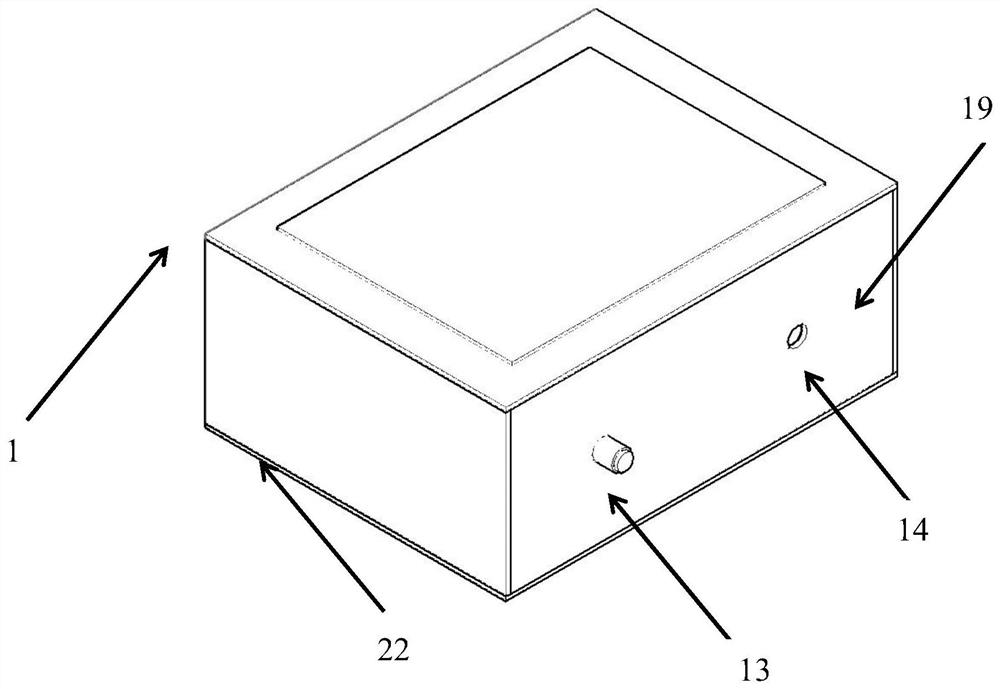

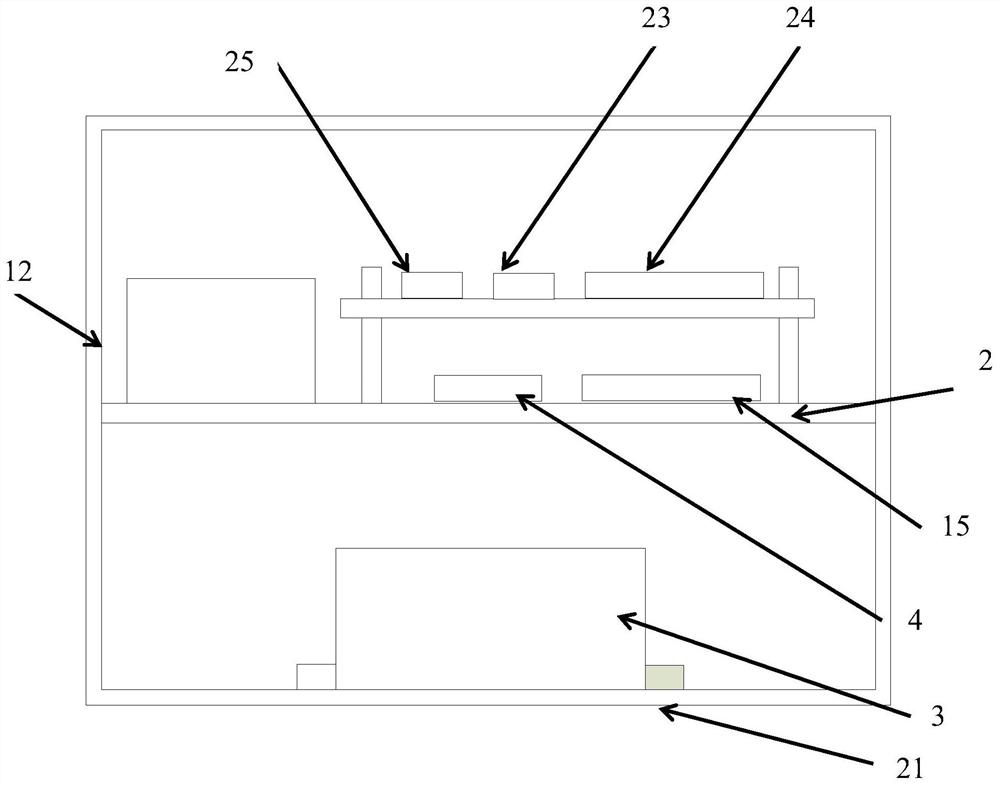

[0019] Such as Figure 1-Figure 4 As shown, the multi-working mode aircraft standby compass calibrator provided by the present invention includes: a housing 1 and a partition 2 installed on the housing 1, a magnetic sensor 3, a horizontal angle sensor 4, a processor module 5, and a compass rotation knob 6. Observation window rotation knob 7, magnetic heading cursor rotation knob 8, observation window lock button 9, horizontal angle sensor orientation button 10, reset switch 11, rechargeable battery 12, power switch 13, charging interface 14, Raspberry Pi module 15 and Electronic display 16; wherein, partition plate 2 is horizontally arranged in the inside of casing 1, thereby casing 1 is divided into upper and lower two spaces; Processor module 5 is respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com