construction paving machine

A technology for construction engineering and paving machines, which can be used in construction, roads, roads, etc., and can solve problems such as lack of cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

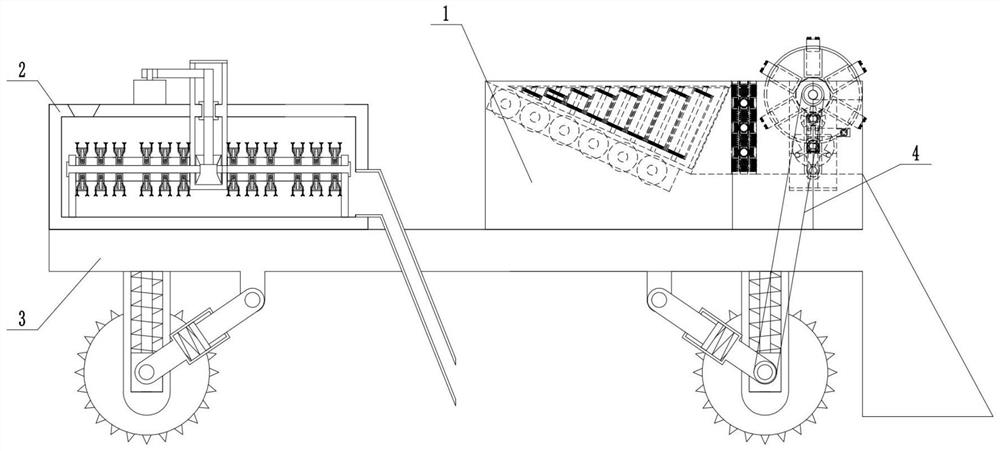

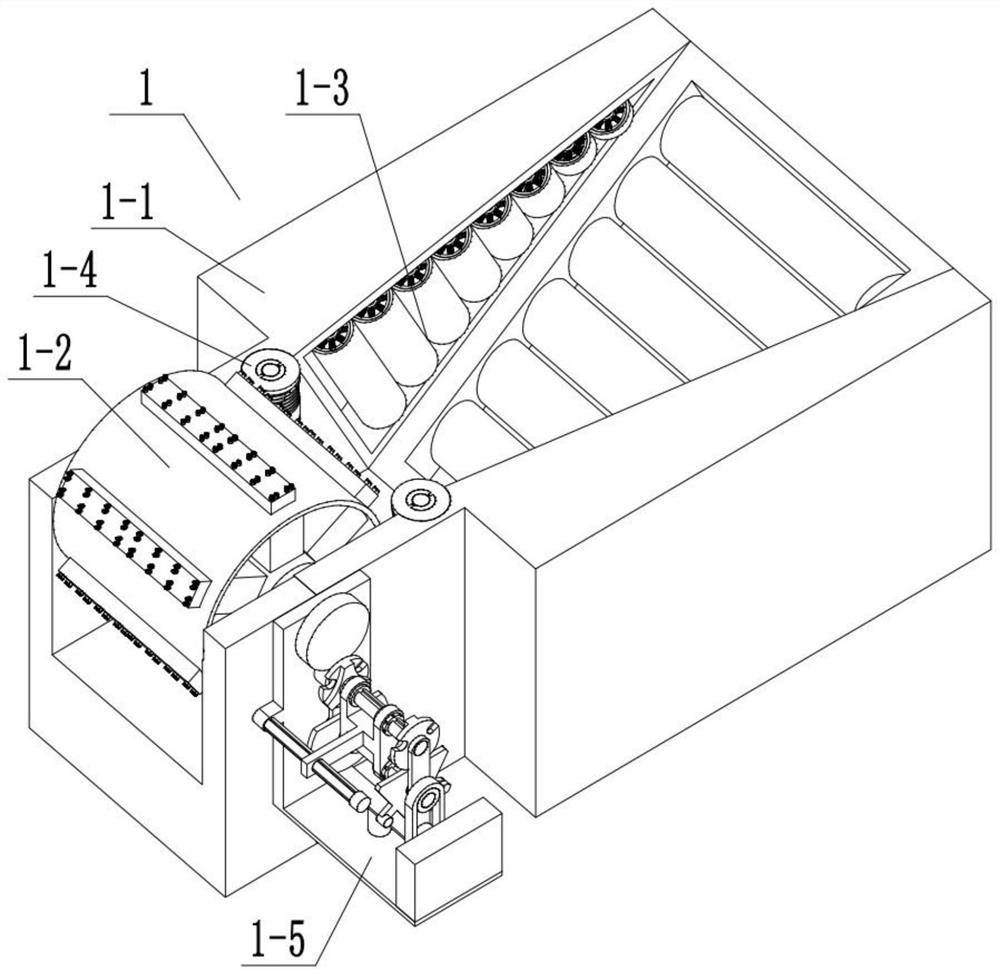

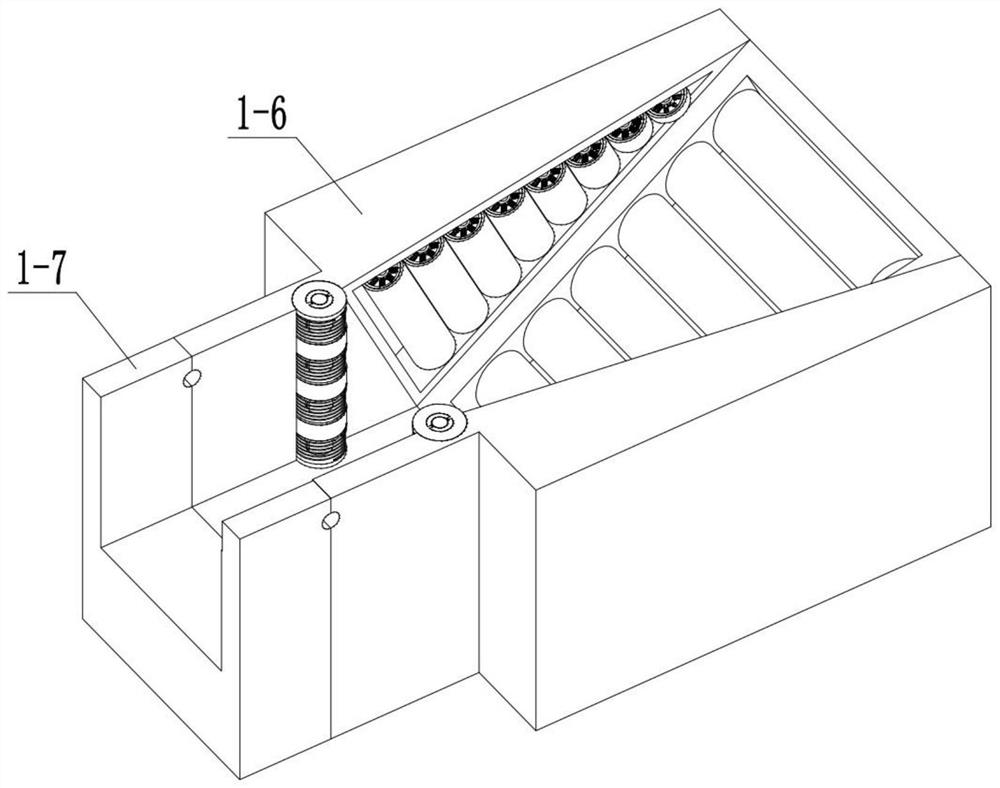

[0041] Combine below Figure 1-24 Description of this embodiment, a construction road paver, including a stone brick assembly 1, a cement mixing assembly 2, a mobile bracket 3 and a drive belt 4, the stone brick assembly 1 includes a stone brick support 1-1, a rolling Roller 1-2, driving roller assembly 1-3, driving roller assembly 1-4, spacing adjustment assembly 1-5, stone brick support body 1-6, connecting frame 1-7, two driving rotating columns 1- 8. Half hole one 1-9, half hole two 1-10, side wall hollow cavity 1-11, rotating column one 1-12, rotating column two 1-13, rotating column three 1-14, rotating column four 1- 15. Rotary column five 1-16, rotary column six 1-17, rotary column seven 1-18, rotary column eight 1-19, lower end roller one 1-20, lower end roller two 1-21, lower end roller three 1-22 , Lower end roller four 1-23, lower end roller five 1-24, lower end roller six 1-25, driving end cover 1-26, driving sleeve 1-27, driving rotating hole 1-28, multiple driv...

specific Embodiment approach 2

[0047] Combine below Figure 1-24 This embodiment will be described, and this embodiment will further describe the first embodiment, the first half hole 1-9 and the second half hole 1-10 form a circular rotary hole.

specific Embodiment approach 3

[0049] Combine below Figure 1-24 This embodiment will be described. This embodiment will further describe the first embodiment, the connecting push spring 2-22 is in a compressed state.

[0050] A kind of construction engineering paving machine of the present invention, its working principle is:

[0051] During use, the stone bricks for paving are placed on the inner end of the stone brick support 1-1, through the stone brick support 1-1 and the lower end roller one 1-20, the lower end roller two 1-21, the lower end roller three 1-22, the lower end roller The rotation connection of roller four 1-23, lower end roller five 1-24 and lower end roller six 1-25 moves from left to right along the inner wall of the stone brick support 1-1 under the action of the gravity of the paving stone brick, and at the same time Start drive motor 1-41. The drive motor 1-41 rotates and drives the transmission pulley 1-43 to rotate through the drive belt 1-42, and through the fixed connection be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com