High-rise building mechanical demolition method based on numerical simulation

A technology for numerical simulation and structures, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of high construction cost, high labor cost, long dismantling time, etc., achieve high speed, low cost, and solve blindness construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

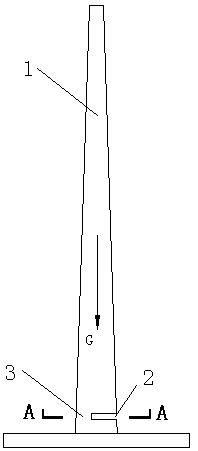

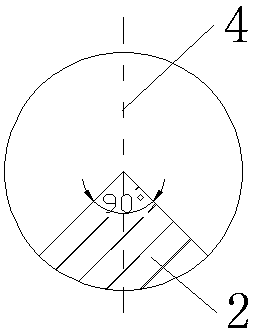

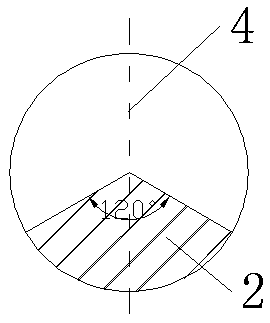

[0051] Such as Figure 7 and 8 As shown, the reinforced concrete chimney of a certain factory needs to be demolished. The height is 45m, the bottom diameter is 4.35m, the top diameter is 1.6m, and the wall thickness is 0.48m. The chimney needs to be demolished due to the renovation of the factory area. In order to ensure safety, we adopted a numerical simulation-based mechanical demolition method for tall structures to remove chimneys. First of all, we measured the strength of the reinforced concrete chimney on site, and the tensile strength of the concrete was about 35MPa and the tensile strength was 5MPa. The chimney is structurally sound with no serious weathering. Through data query, the density of the reinforced concrete chimney is 2500Kg / m3, and the elastic modulus E is 35Gpa. The above data are used as the basic data for numerical simulation. Secondly, the gap treatment length simulation design is carried out. Due to the relatively large rigidity of the chimney, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com