A three-dimensional numerical simulation method for extrusion strengthen process of turbine disk hole

A three-dimensional numerical and simulation technology, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve problems such as unstable residual stress, high surface roughness, and small residual stress field depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

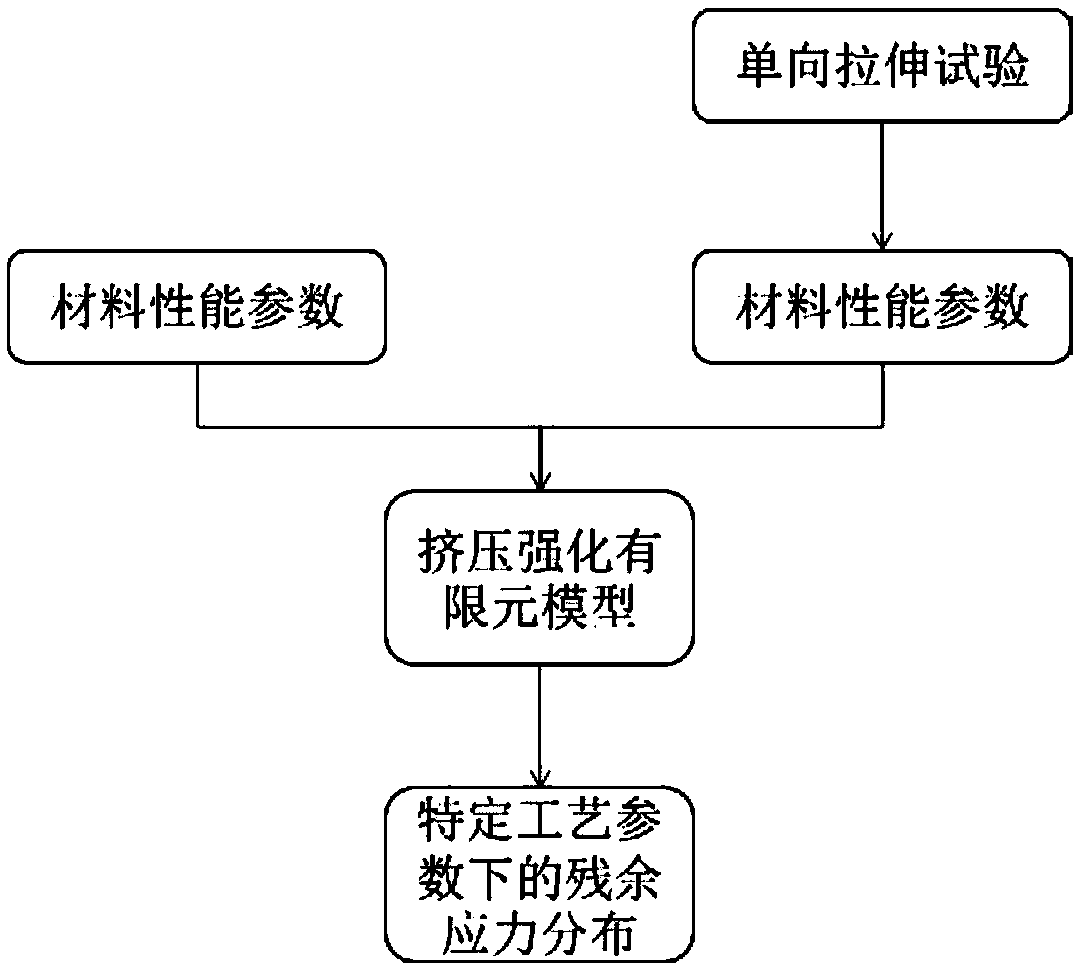

[0022] Such as figure 1 Shown, the present invention realizes steps as follows:

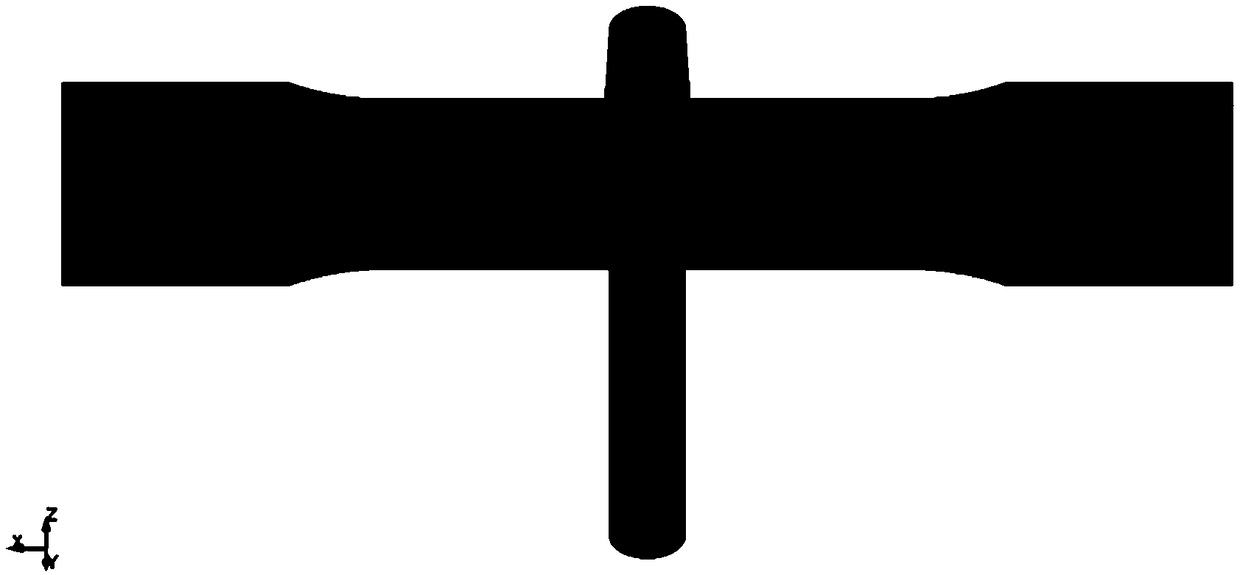

[0023] (1) Three-dimensional modeling of the extrusion strengthening process: first, carry out the three-dimensional model design of the mandrel and the central circular hole plate, and design the central circular hole plate and the mandrel with a certain amount of interference according to the real nickel-based superalloy turbine disk structure Dimensions and shapes, establish a three-dimensional model of the central circular hole plate and mandrel.

[0024] (2) Establish the finite element model of the hole extrusion strengthening process: obtain the material properties of the turbine disc structure through the material performance test or material data booklet selected by the turbine disc; complete the setting of material properties and parameters, and use a three-dimensional hexahedron element to divide The finite element mesh is used to refine the mesh in the contact area between the mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com