Automatic identification method for plate edges

A technology of automatic identification and sheet material, which is applied in the direction of cooperative operation devices, instruments, computer parts, etc., can solve the problem of inability to realize one-time identification of sheet material identity and processing edge information, etc., to improve the speed of coding or pasting, control Cost, labor reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

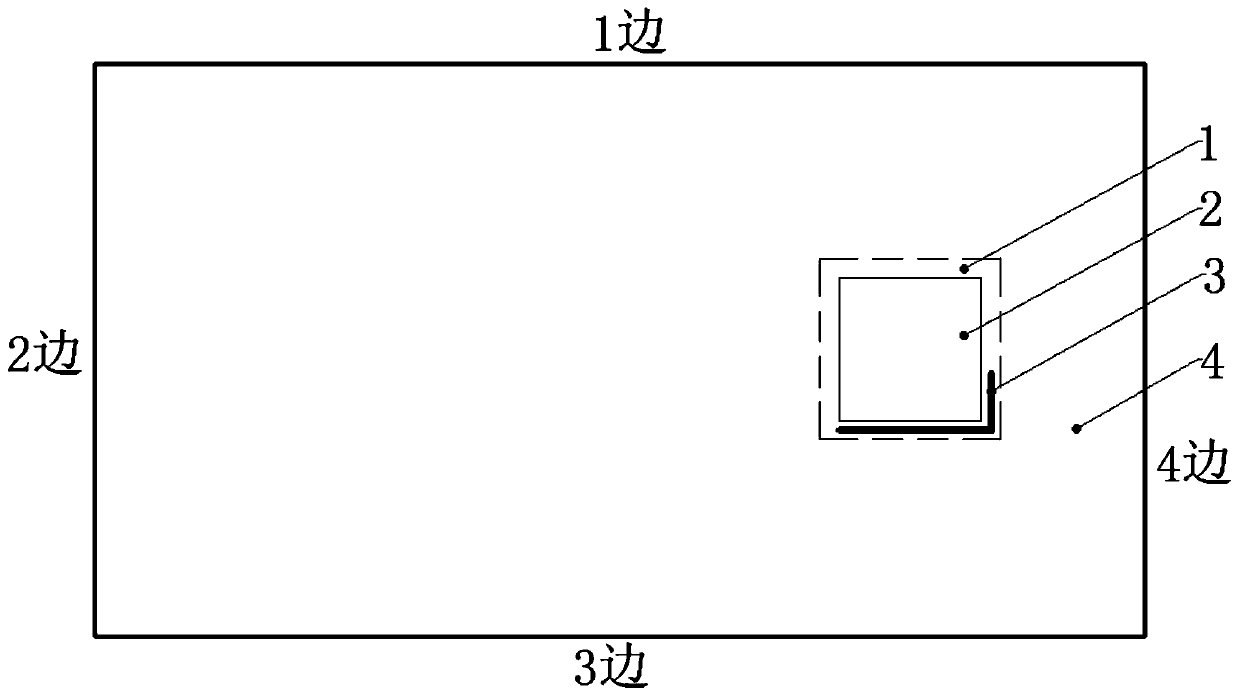

[0024] like figure 1 shown.

[0025] A method for automatic identification of plate edges, which comprises the following steps:

[0026] First, define the feature edge of the plate;

[0027] Secondly, define a feature code for the feature side of the plate; the feature code is a pattern or line that matches the adjacent long and short sides of the plate or is consistent with the direction of the plate to be processed;

[0028] Third, spray or paste the identification code (including standard information codes such as two-dimensional codes and barcodes, etc., this embodiment uses the two-dimensional code as an example) while spraying or pasting the identification code on the edge of the identification code To reduce the production preparation time of inkjet or sticky code;

[0029] Fourth, use the camera to obtain the identification code information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com