Method for detecting curved edge sub-pixels in laser tailor-welding image of to-be-welded piece

A technology of laser tailor welding and detection method, applied in the field of visual inspection, can solve the problems such as robustness to be improved, easily affected by noise, etc., and achieve the effect of stable and fast calculation process and simple selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

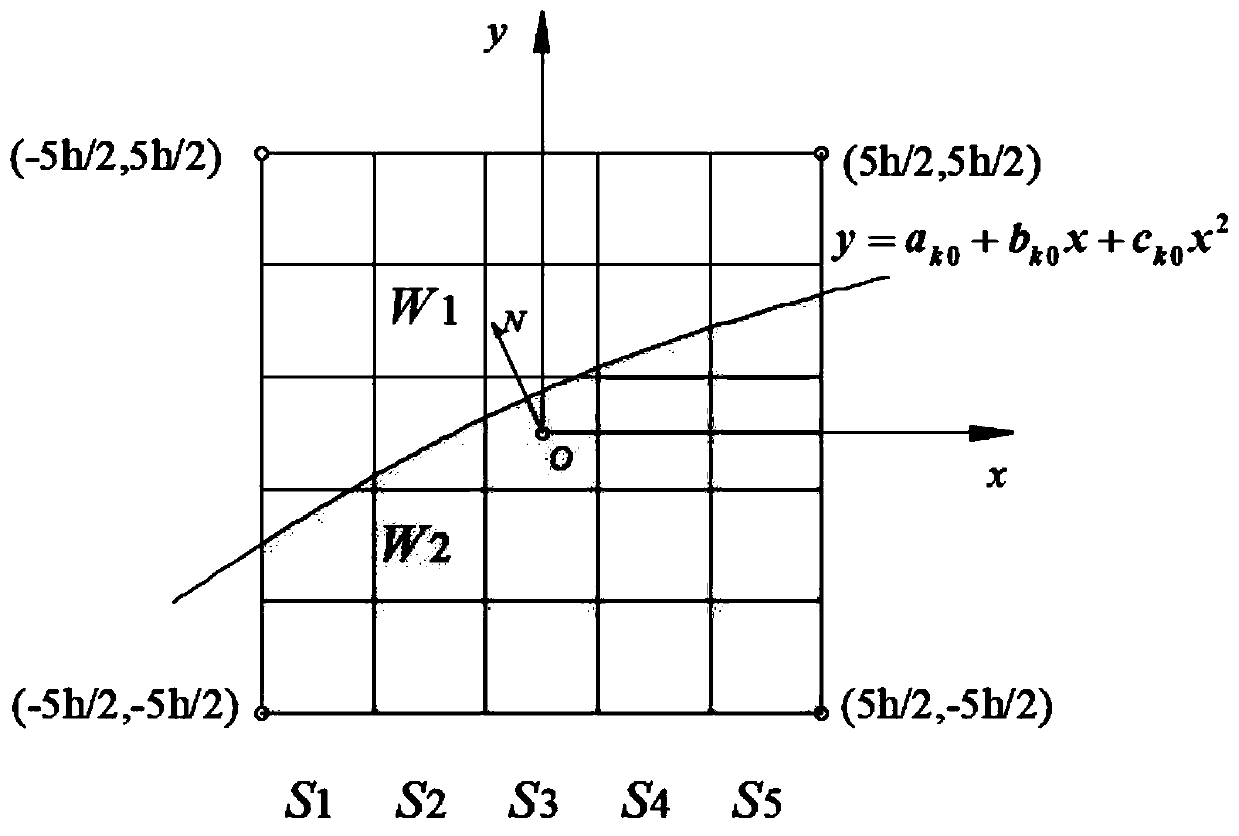

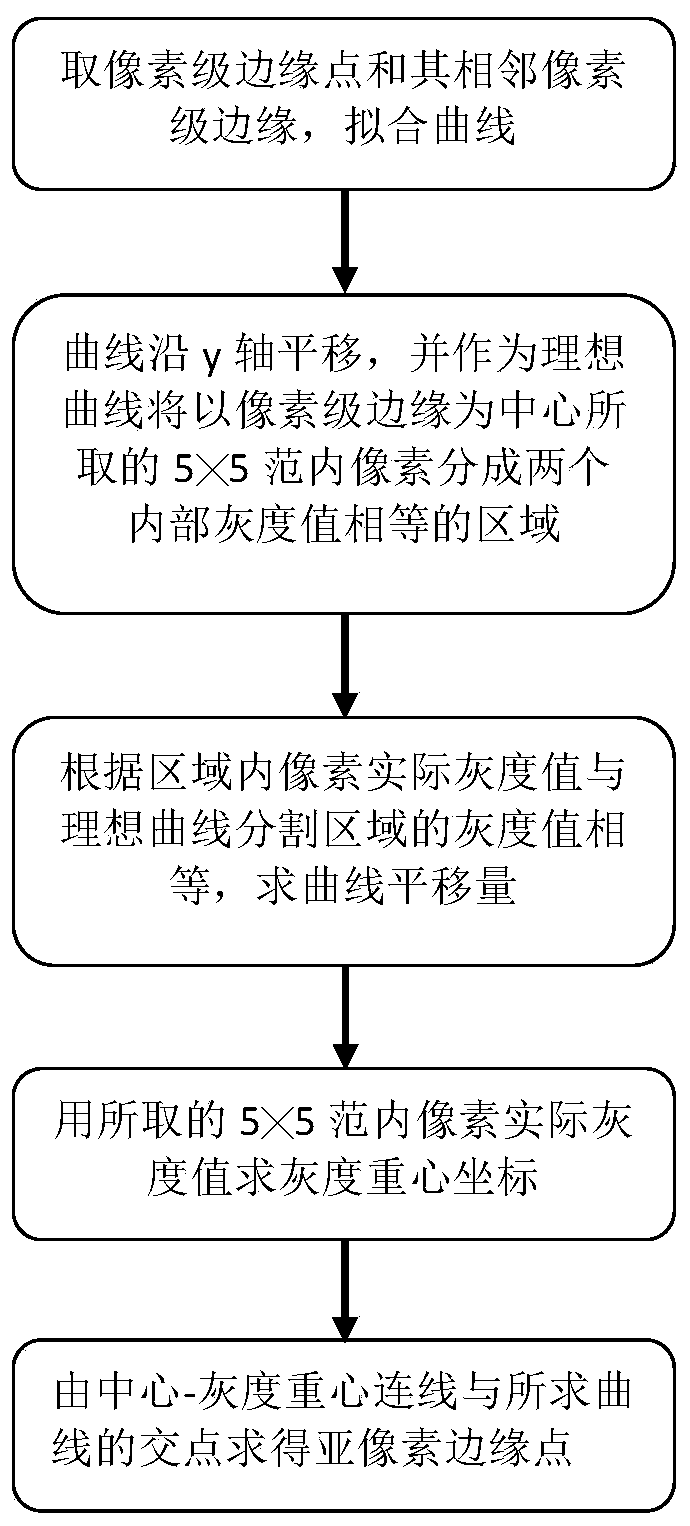

[0038] This embodiment provides a sub-pixel detection method of a curve edge in an image of a laser tailor welding to-be-welded piece. The welding head used in this method is installed on the numerical control machine tool. The industrial CCD camera is installed on the welding head and moves synchronously with the welding head. Using the Sobel edge detection algorithm to obtain the pixel-level edge points (i k ,j k ), k=1,2,...n (n is the number of pixel-level edge points). Take pixel-level edge points (i k ,j k ), the specific steps to find the corresponding sub-pixel edge point are as follows:

[0039] The first step is to fit the curve with pixel-level edge points

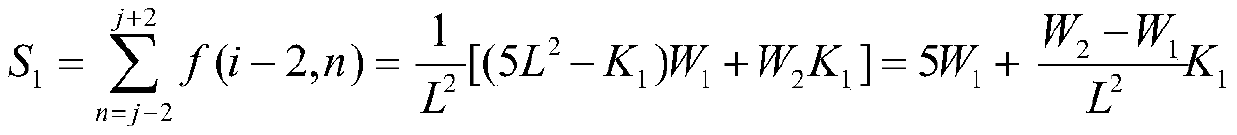

[0040] Pixel-level edge points (i k ,j k ) is the coordinate origin O, and a coordinate system is established with the horizontal direction as the x-axis and the vertical direction as the y-axis. Take another 4 adjacent pixel-level edge points and fit the quadratic curve l k , its expression is y=a k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com