a kind of in 2 the se 3 Organic solar cell as hole transport layer and preparation method thereof

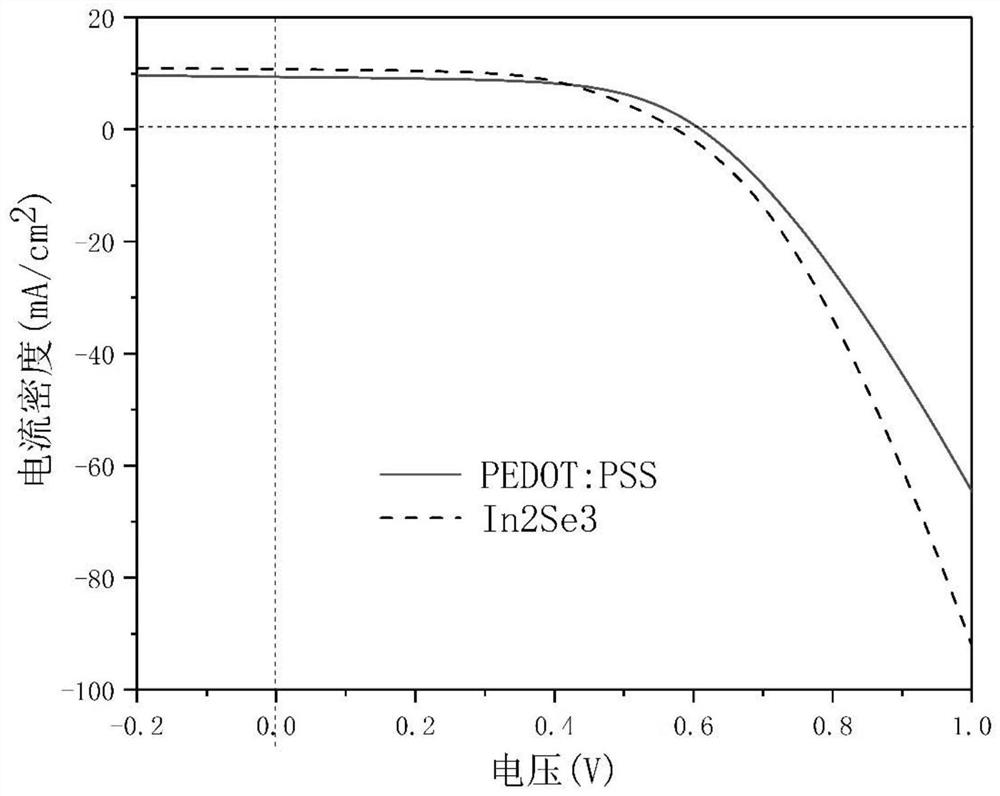

A hole transport layer and solar cell technology, applied in the field of solar cells, can solve the problems of device stability, limited charge transmission and collection, low light transmittance, etc., and achieve the effect of reducing sensitivity and improving charge transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, In 2 Se 3 The organic solar cell device structure as the hole transport layer is: ITO / In 2 Se 3 / P3HT:PCBM / Ca / Al.

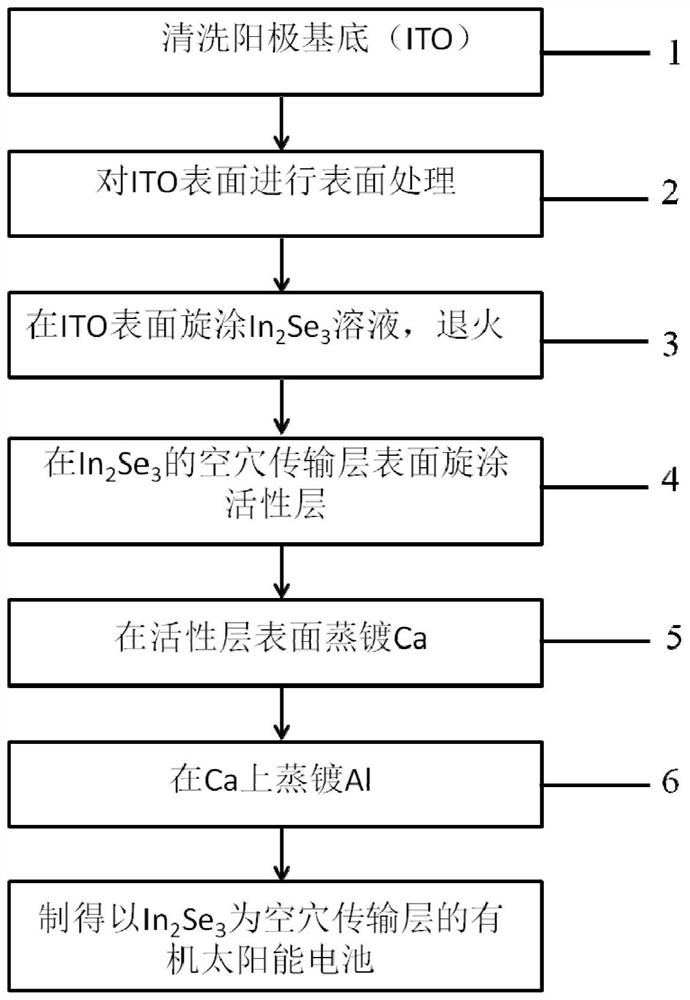

[0038]above with In 2 Se 3 The preparation process of the organic solar cell for the hole transport layer is as follows:

[0039] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol for 20 minutes in sequence; then dry in a vacuum oven at 80°C;

[0040] Step 2, carry out 13 minutes of plasma surface treatment on the surface of the anode substrate (ITO) of described cleaning and drying, this treatment method utilizes the strong oxidizing property that generates ozone under microwave to clean residual organic matter etc. on ITO surface, can make ITO surface oxygen simultaneously Increased vacancies improve the work function of the ITO surface;

[0041] Step 3. Spin-coat In on the ITO surface treated in step 2 2 Se 3 solution; the In 2 Se 3 The solution preparation process is as f...

Embodiment 2

[0050] In this embodiment 2, In 2 Se 3 The organic solar cell device structure as the hole transport layer is: ITO / In 2 Se 3 / P3HT:PCBM / Ca / Al.

[0051] above with In 2 Se 3 The preparation process of the organic solar cell for the hole transport layer is as follows:

[0052] Step 1. Use detergent, deionized water, acetone, absolute ethanol, and isopropanol to ultrasonically clean for 15 minutes in sequence; this time, dry in a vacuum oven at 80°C;

[0053] Step 2, carry out 15 minutes of plasma surface treatment on the surface of the anode substrate (ITO) that has been cleaned and dried. This treatment method utilizes the strong oxidative property of generating ozone under the microwave to clean the residual organic matter on the ITO surface, etc., and simultaneously can make the ITO surface oxygen Increased vacancies improve the work function of the ITO surface;

[0054] Step 3. Spin-coat In on the ITO surface treated in step 2 2 Se 3 solution; the In 2 Se 3 The so...

Embodiment 3

[0060] In this embodiment 3, In 2 Se 3 The organic solar cell device structure as the hole transport layer is: ITO / In 2 Se 3 / P3HT:PCBM / Ca / Al.

[0061] above with In 2 Se 3 The preparation process of the organic solar cell for the hole transport layer is as follows:

[0062] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol for 17.5 minutes in sequence; this time, dry in a vacuum oven at 85°C;

[0063] Step 2, carry out 14 minutes of plasma surface treatment on the surface of the anode substrate (ITO) of described cleaning and drying, this treatment method utilizes the strong oxidizing property that generates ozone under the microwave to clean the residual organic matter etc. on the ITO surface, and simultaneously can make the ITO surface oxygen Increased vacancies improve the work function of the ITO surface;

[0064] Step 3. Spin-coat In on the ITO surface treated in step 2 2 Se 3 solution; the In 2 Se 3 The so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com