Reagent bottle, reagent uniform mixing device and reagent uniform mixing method

A reagent bottle and reagent technology, applied in the field of medical devices, can solve problems such as reagent mixing and cross infection, and achieve the effects of avoiding cross infection, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

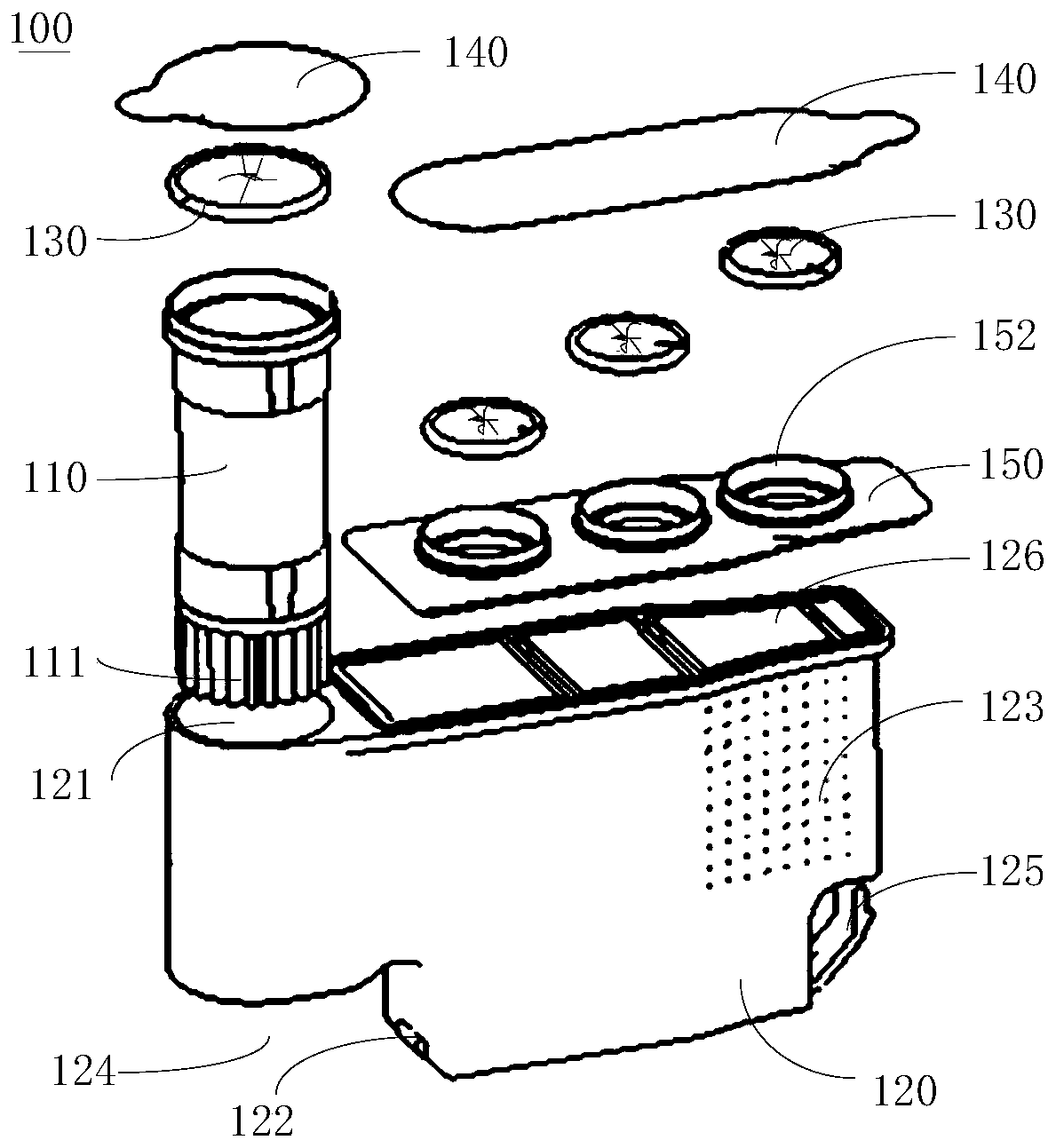

[0039] see figure 1 with figure 2 , a reagent mixing device, including a reagent bottle 100 and a driving device 200. The reagent bottle 100 includes a reagent bottle body 110 and a reagent bottle base 120 . The reagent mixing device can achieve the function of mixing reagents (such as solid phase reagents) and the like.

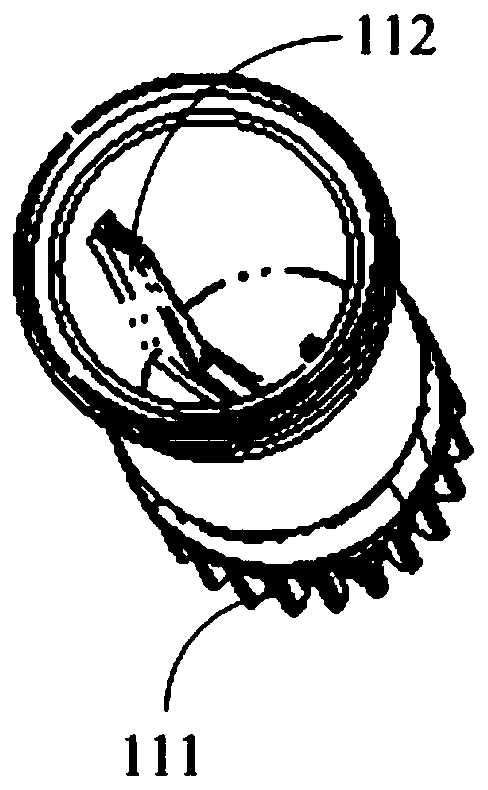

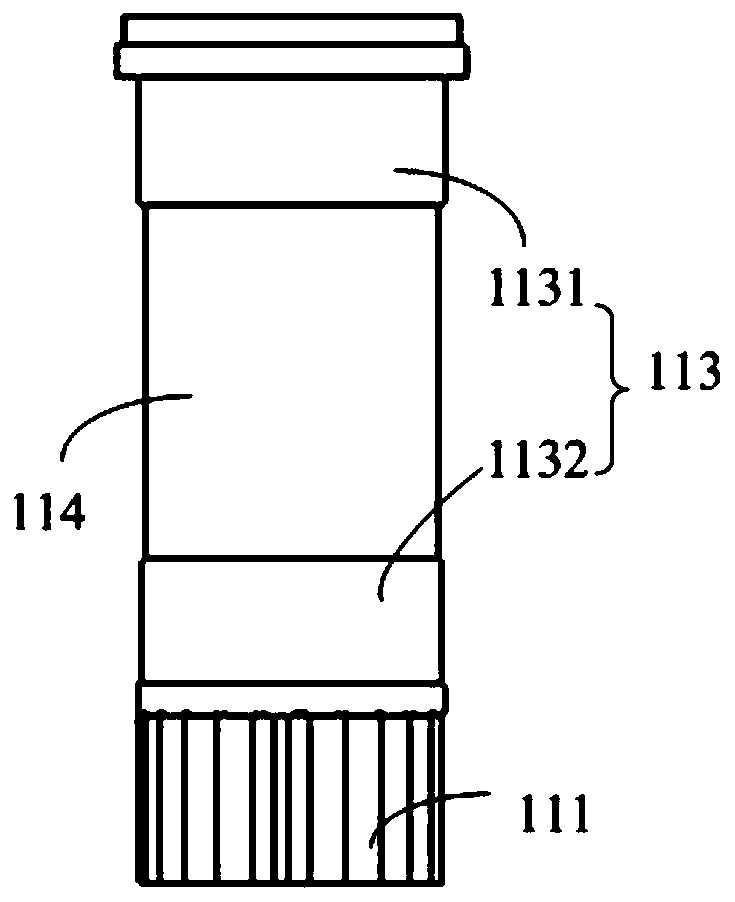

[0040] Specifically, see figure 2 with image 3 , the reagent bottle 100 includes a reagent bottle body 110 and a reagent bottle base 120 that can be installed on the mounting mechanism 210, the reagent bottle base 120 is used to load the reagent bottle body 110; the reagent bottle base 120 is provided with a The through hole 121 where the reagent bottle body 110 is inserted; the reagent bottle body 110 is provided with a transmission part, and the reagent bottle body 110 can be driven by the transmission part and the driving device 200 in the through hole 121 Rotate. The outer diameter of the opening end of the reagent bottle body 110 can be greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com