The Method of Grinding Tapered Roller by Self-positioning Device with Buffer on Spherical Surface Grinding Machine

A tapered roller, self-positioning technology, applied in the field of bearing grinding, can solve the problems of large grinding efficiency with end face circular runout fluctuation, large curvature dispersion of the spherical base surface, and non-continuous adjustment of the curvature radius of the spherical base surface. Grinding accuracy and grinding efficiency, reducing the effect of large curvature dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

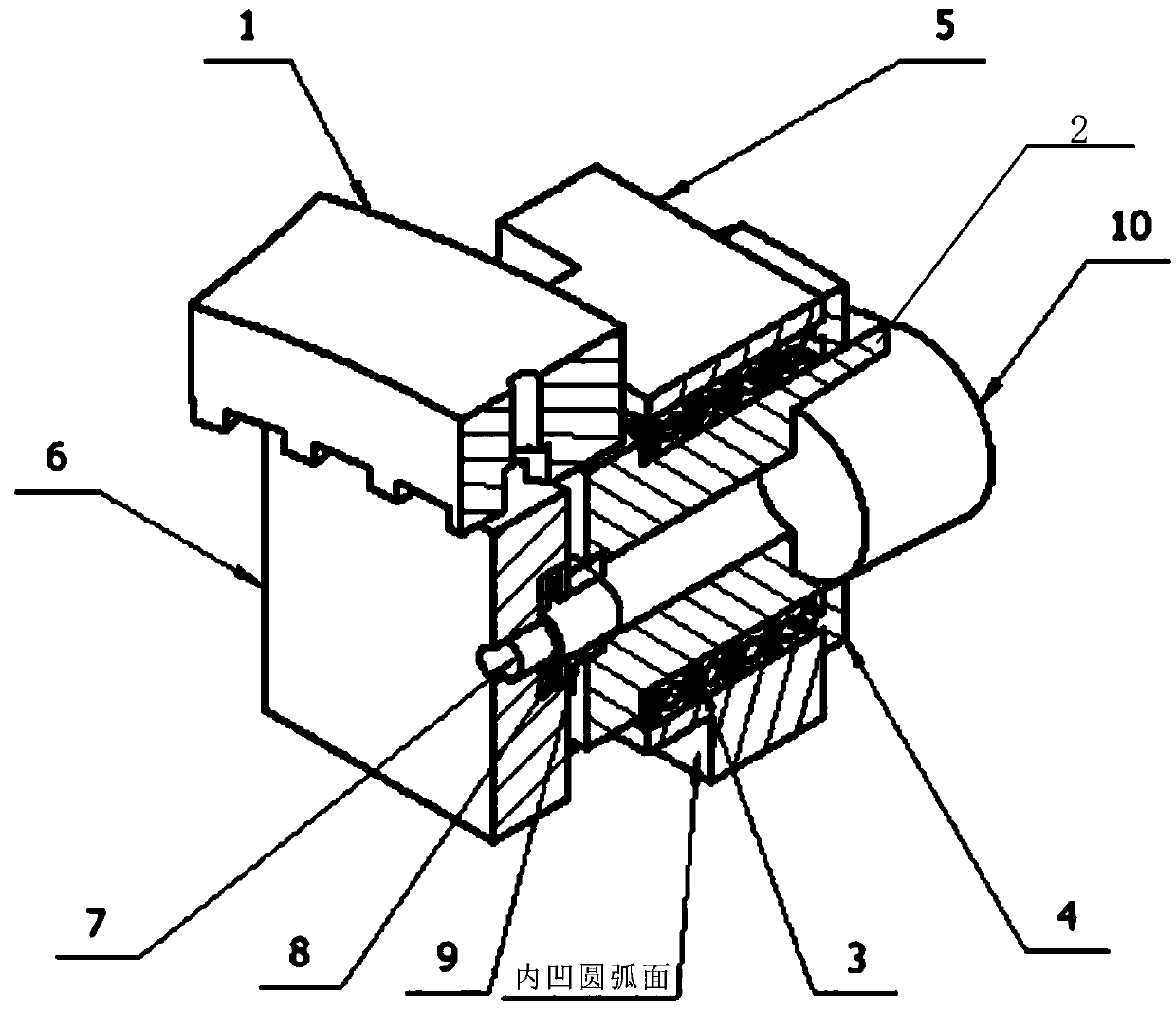

[0018] The invention relates to a method for grinding tapered rollers by a spherical surface grinder with a self-positioning device with a buffer. The method uses a set of self-positioning devices with a buffer. There are technical problems such as the radius of curvature of the ball base surface cannot be adjusted continuously, the curvature of the ball base surface has large dispersion, the end face circle runout fluctuates greatly, and the grinding efficiency is low.

[0019] Generally speaking, the spherical surface grinding machine is equipped with a workpiece rotary table, and the workpiece rotary table is connected with a lower rotary table.

[0020] combine figure 1 , the self-positioning device with buffer includes a gear plate 1, a gear shaft 2, a rolling bearing 3, an outer gland 4, a housing 5, a back seat 6, a positioning shaft 7, a thrust bearing 8 and a buffer bushing 9, and the buffer For the structural connection method of the self-positioning device, please ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com