Final state network optimizing method for double-arm mechanical hand synchronous repeated motion planning

A technology of repetitive motion and network optimization, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of repetitive motion that cannot be applied to solve periodic motions, and the difficulty of predicting the motion trajectory of dual-arm manipulators. Achieve and improve the effect of convergence accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

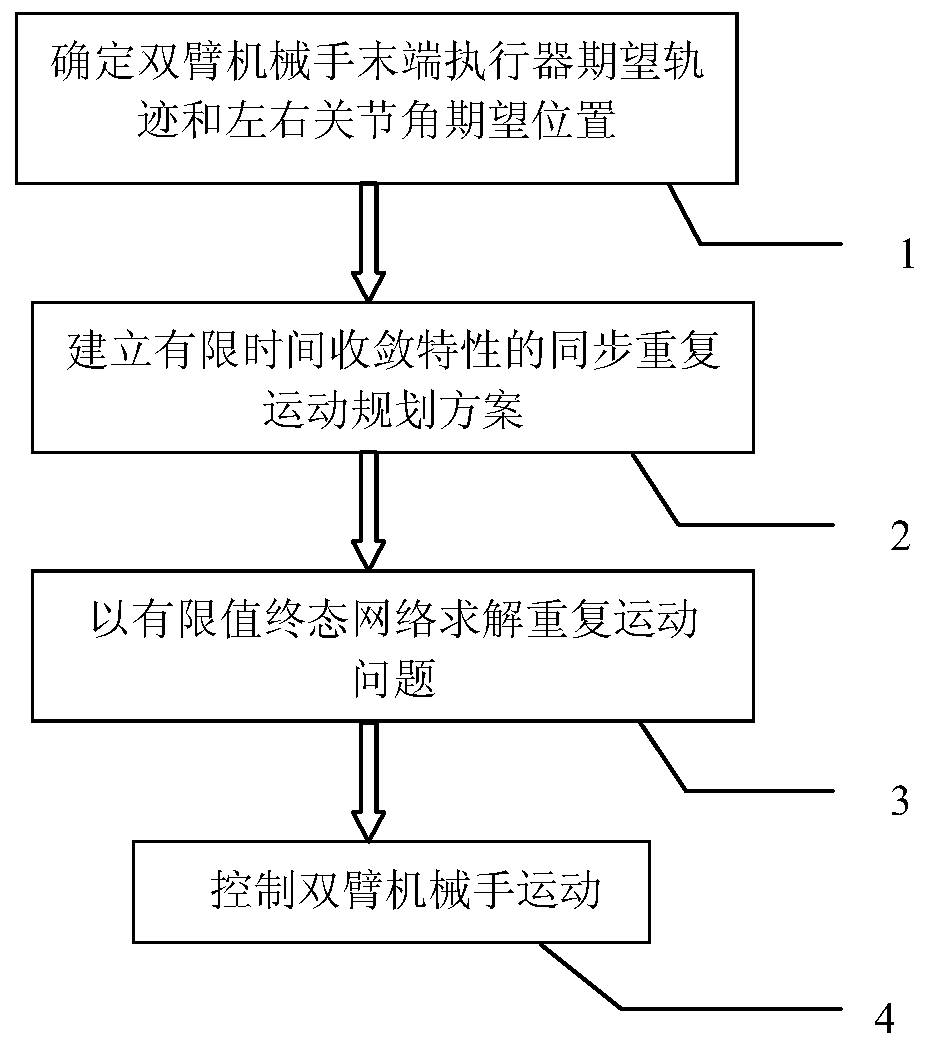

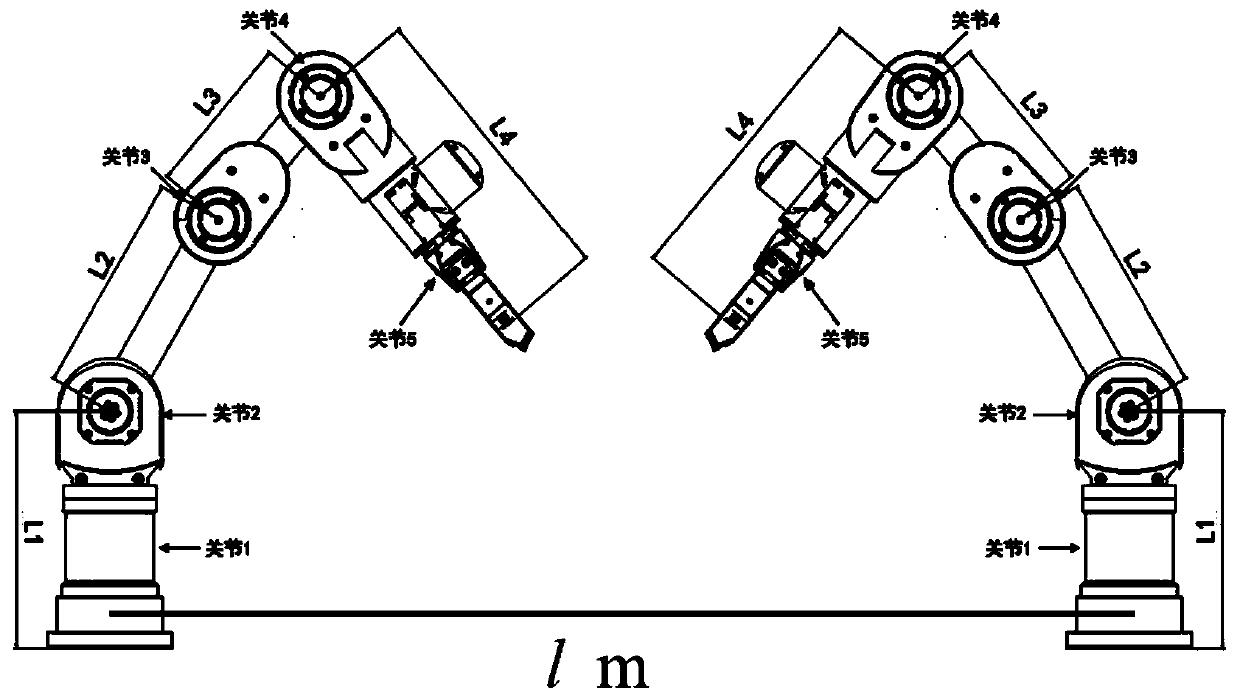

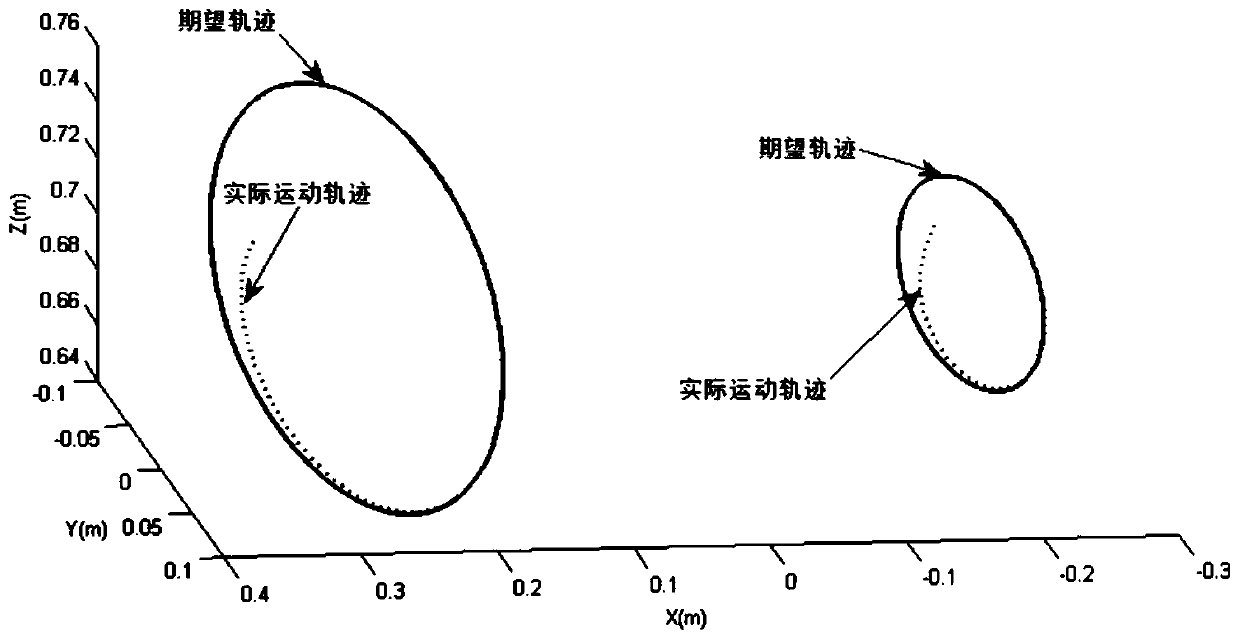

[0042] refer to Figure 1 to Figure 6, a final state network optimization method for dual-arm manipulator synchronous repetitive motion planning, which consists of the following four steps: 1. Determine the expected target trajectory and the expected return angle of each joint of the left and right end effectors of the dual-arm manipulator respectively. 2. Establish a Quadratic programming scheme for dual-arm manipulator with finite-time convergence characteristics for synchronous repetitive motion 3. Solve the quadratic programming problem with a finite-valued final state network to obtain the angular trajectories of the left and right kinematic joints. 4. Drive the motor to run with the result obtained from the solution, so that the robot arm can complete the trajectory task.

[0043] The first step is to determine the desired trajectory

[0044] Set the angles of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com