A four-blade rotary wing and rotary wing aircraft and control method

A technology of rotating wings and blades, which is applied in the field of heavy-duty rotary-wing aircraft, can solve problems such as sharp increase in power consumption, increase in longitudinal distance of aircraft, increase the load capacity and maximum take-off weight of rotary-wing aircraft, and achieve The effect of increasing power consumption and increasing the maximum pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

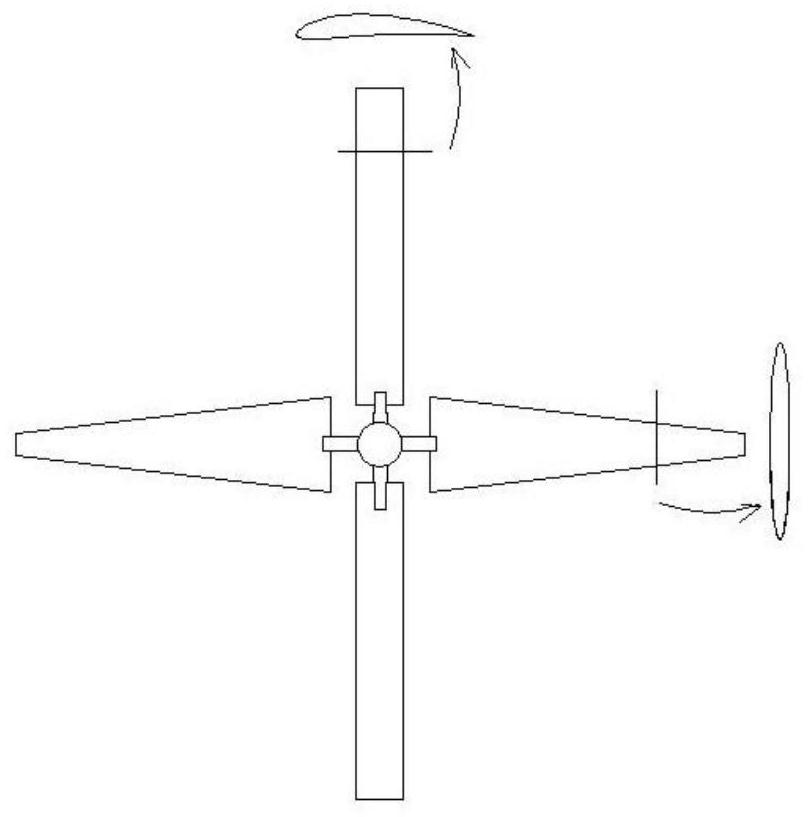

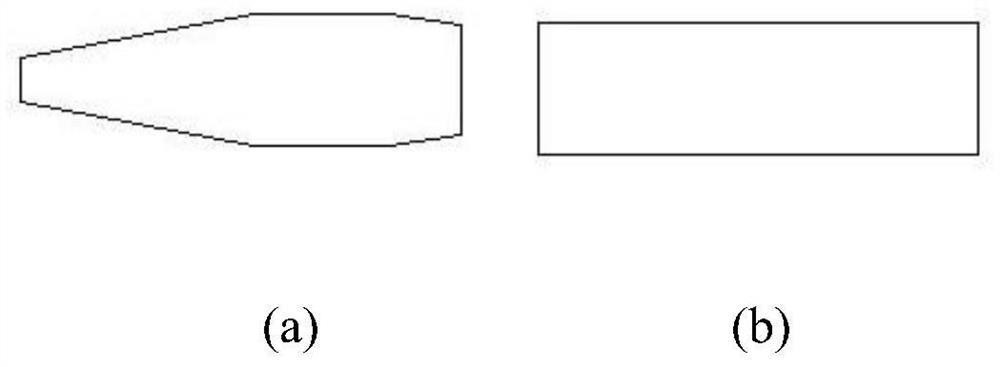

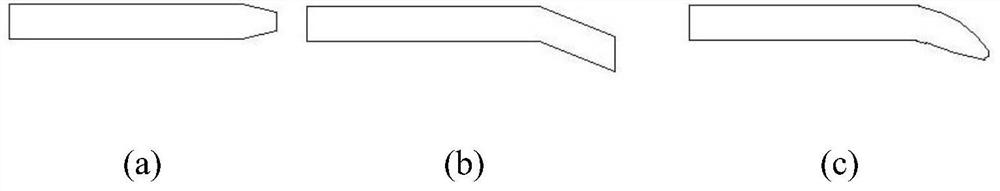

[0048] first as figure 1 As shown, a four-blade rotary wing is proposed in this embodiment, which is mainly composed of two sets of blades of different configurations, that is, a "main and auxiliary blade" comprising a pair of main blades and a pair of auxiliary blades. "System composition. Among them, the main blade is designed to meet the requirements of both fixed-wing mode and helicopter mode. The profile of the blade adopts a symmetrical airfoil design at the front and rear edges, such as an elliptical airfoil. etc., such as figure 2 shown. The other pair of auxiliary blades are completely designed to meet the flight requirements of the helicopter mode. The high-performance rotor design can be used with a high aspect ratio. The blade section adopts a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com