Fastening system

A technology for fastening and tightening elements, applied in the direction of quick-acting fasteners, detachable fasteners with friction clamping, connecting members, etc., can solve the problems of cost, undesired release of clamping protrusions, and work. , to achieve the effect of improving the maximum pull-out force and reliable confinement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

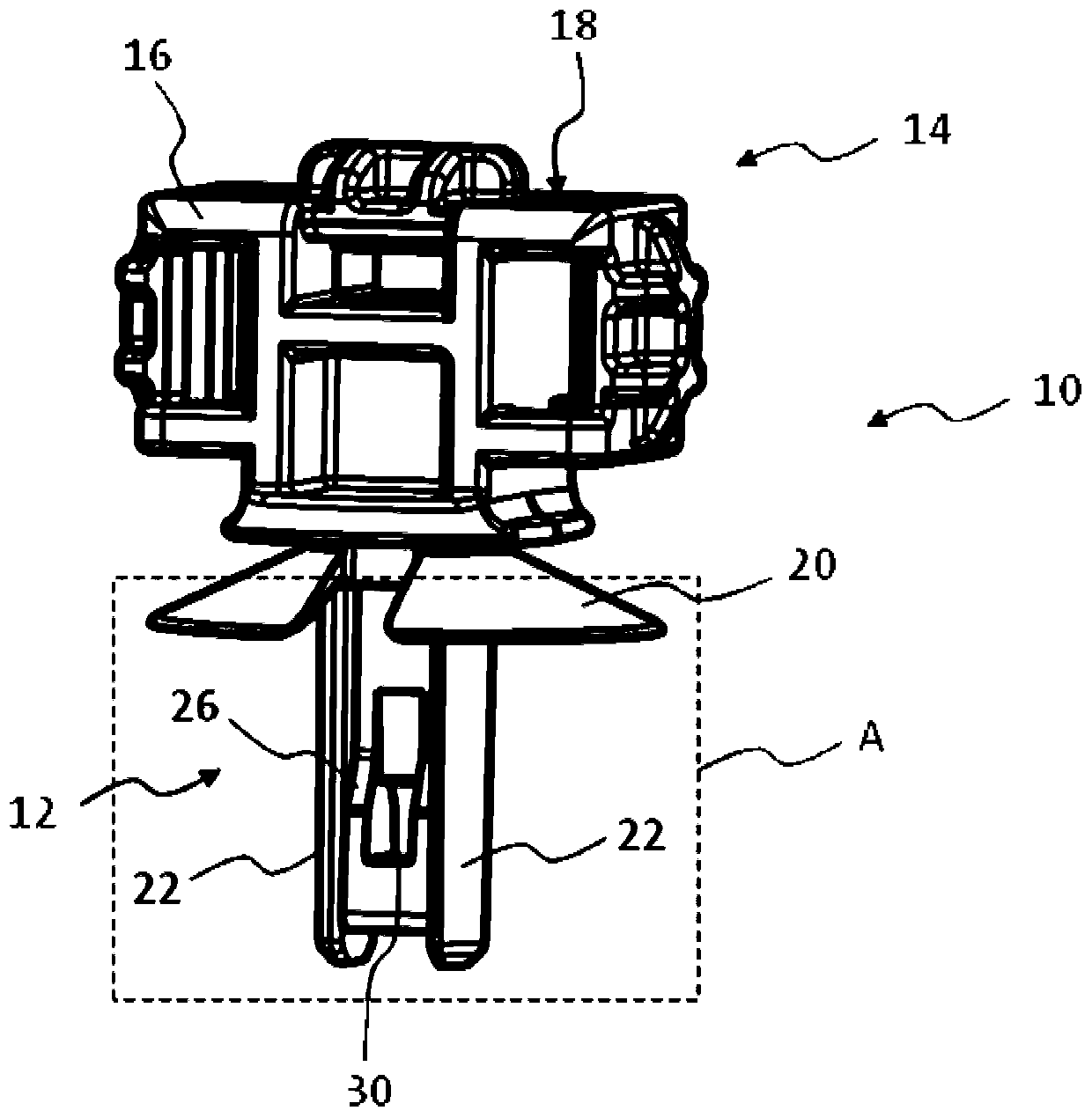

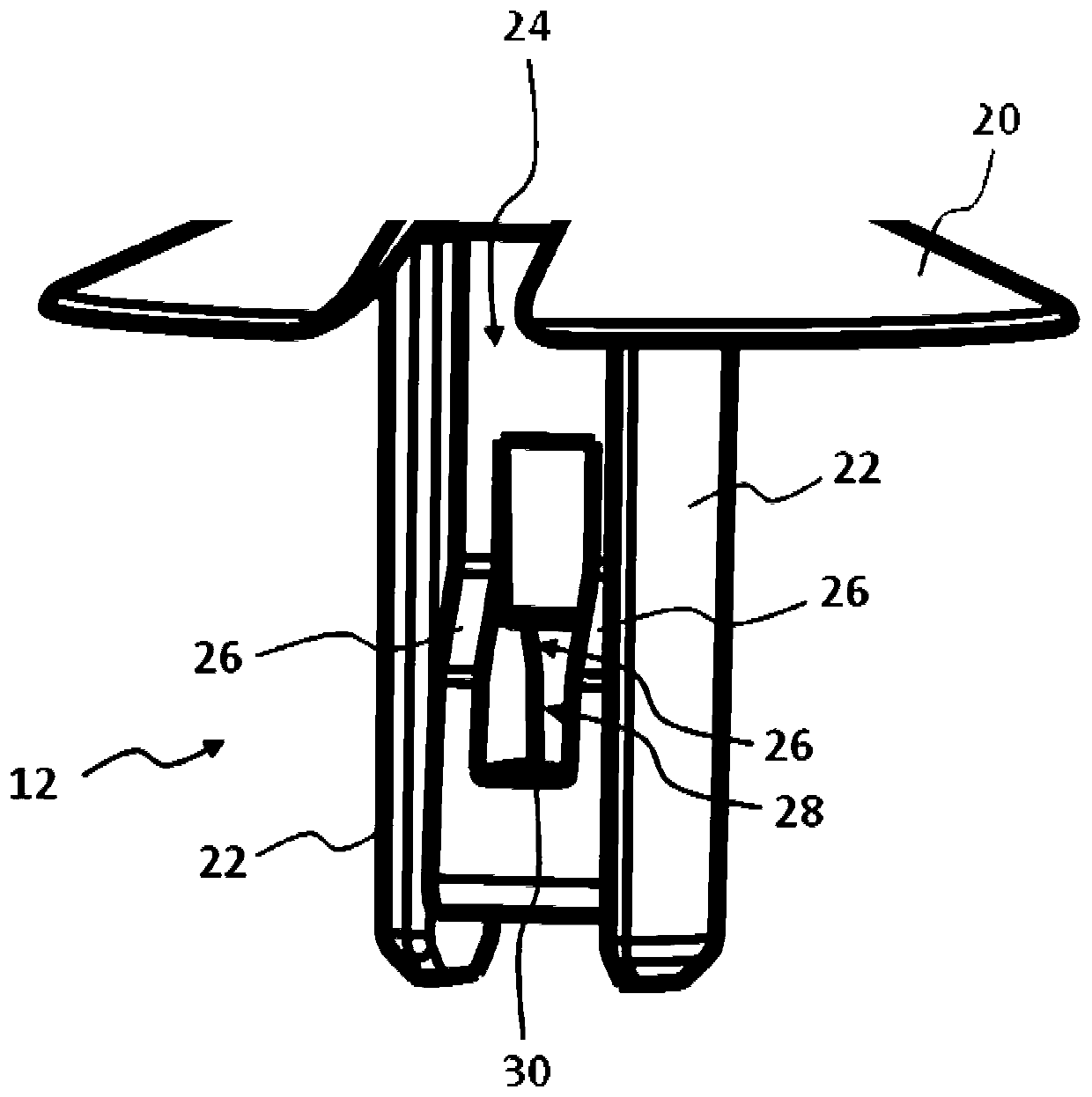

[0038] exist figure 1 and 2 The fastening element 10 shown in has an elongated guide 12 and a head 14 . The head 14 has a holder 16 on which an object, such as a wire harness, can be held. For this purpose, the holding part 16 has, in a manner known per se, a plurality of through-openings 18 through which the cable harness to be held can be drawn. Furthermore, the head 14 has an elastic bearing 20 . Guide part 12 (its longitudinal axis is in figure 1 and 2 Extending in the vertical direction) can be along the insertion direction (in the figure 1 and figure 2 vertically from top to bottom) into the receiving part of the carrier member. In the inserted state into the receptacle, the bearing 20 is supported on the upper side of the carrier part. In the present example, the fastening element 10 is constructed in one piece and is made of plastic. The fastening element 10 can be produced, for example, in a plastic injection molding process.

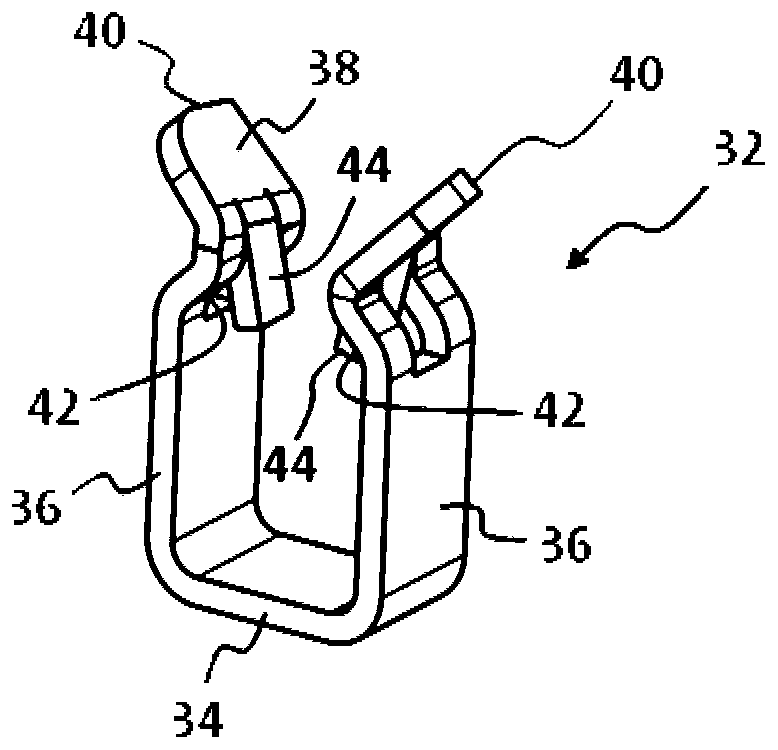

[0039] The design scheme of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com