Adhesive, its preparation method and lithium ion secondary battery prepared thereby

A lithium-ion battery and adhesive technology, which is applied in the direction of adhesives, battery electrodes, adhesive types, etc., can solve problems such as insufficient adhesive force, water-based negative electrode sheet falling off, sticking rollers, etc., to promote mutual dissolution and sliding small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The preparation method of adhesive comprises the steps:

[0029] (1) Separately weigh oleic acid styrene-butadiene rubber and rosin styrene-butadiene rubber to carry out masticating separately, after oleic acid styrene-butadiene rubber and rosin styrene-butadiene rubber are in molten state, carry out mixing again, make it mix evenly;

[0030] (2) Add plasticizer diethylene glycol dibenzoate, large white oil, antioxidant 2,6-di-tert-butyl p-cresol and solvent naphtha 120 of weighing (seeing experimental examples 1-7 behind) , Stir at a temperature of 75-80°C for 5-6 hours to make it evenly mixed.

[0031] The preparation of negative electrode slurry: negative electrode slurry comprises graphite FSN-1, conductive agent SFG-6, tackiness agent, CMC (sodium carboxymethyl cellulose), water (H 2 O) as solvent, its preparation method comprises the steps:

[0032] The first step: Divide the solvent into two parts according to the ratio of 3:7, mix and stir with CMC respectivel...

experiment example 1

[0040] Adhesive ratio:

[0041] Oleic acid styrene butadiene rubber: rosin styrene butadiene rubber: plasticizer: white oil: antioxidant: solvent = 18: 14: 2.0: 1.5: 0.75: 100

[0042] Proportion of negative electrode slurry:

[0043] FSN-1 (graphite): SFG-6 (conductive agent): SBR: CMC: solvent = 100: 2.12: 4.23: 1.59: 94

[0044] According to the test results of negative electrode sheet and battery prepared by the method of above-mentioned embodiment:

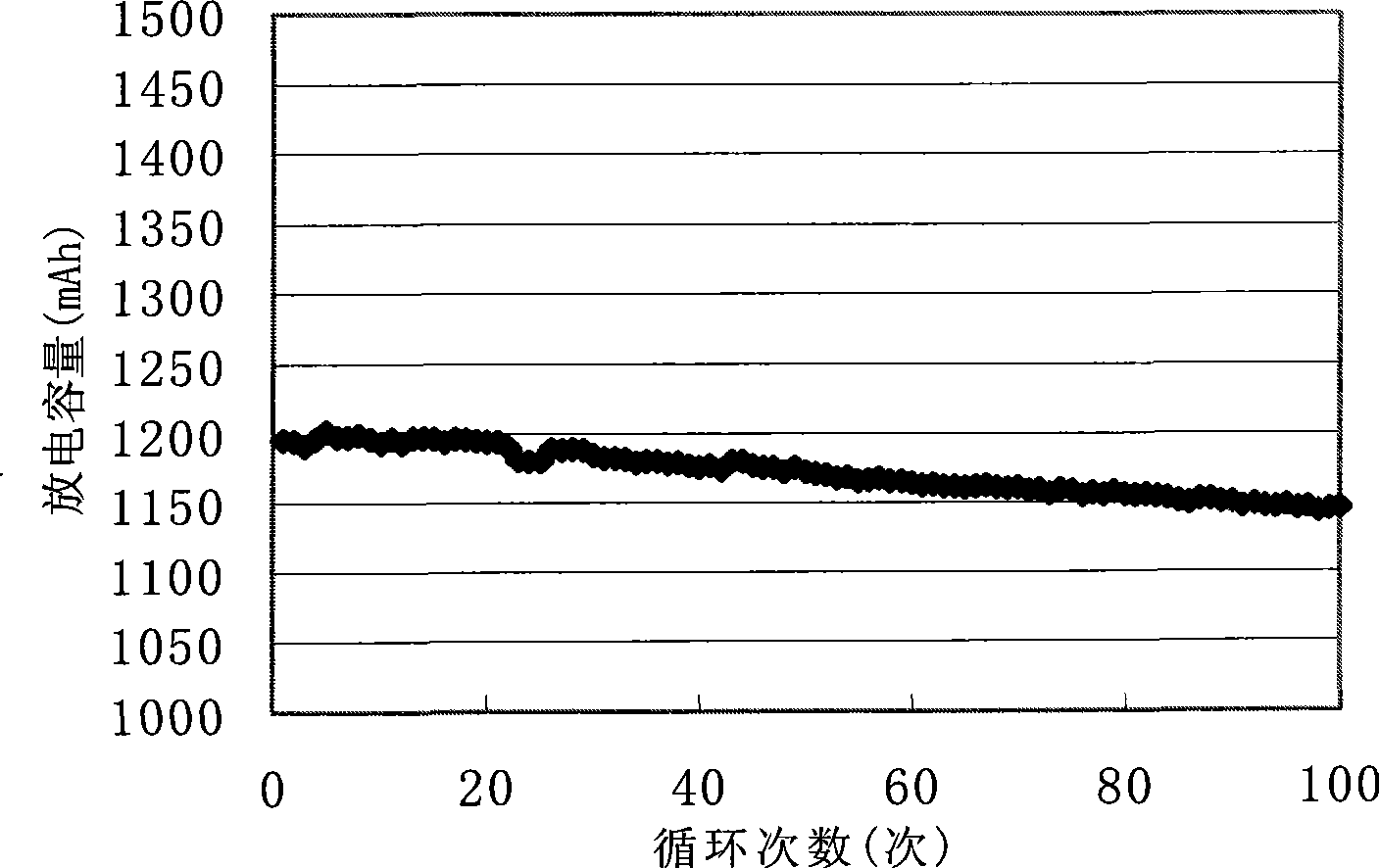

[0045] figure 1 It is the 1C cycle discharge capacity curve of the 18650 battery made in Experimental Example 1 of the present invention.

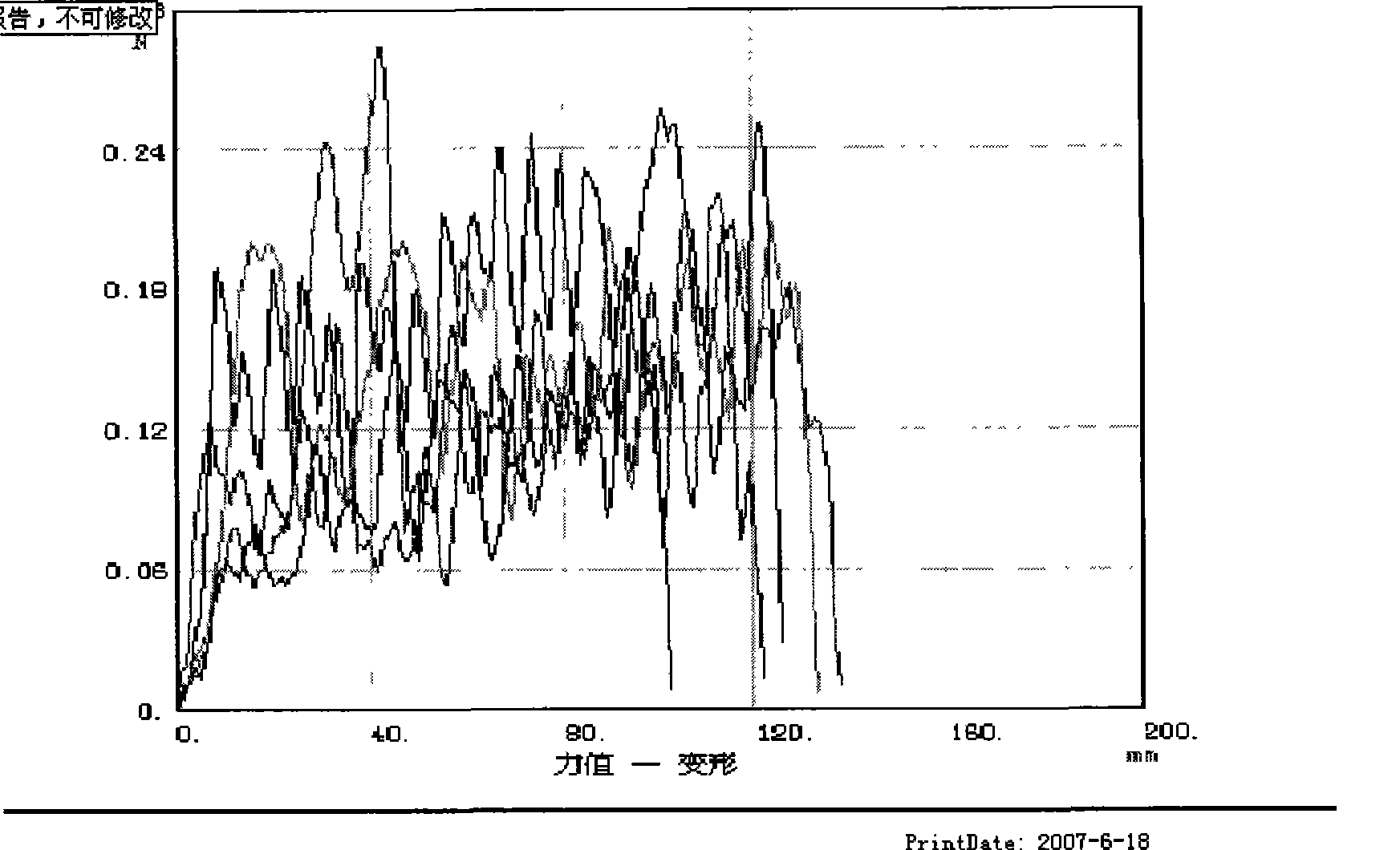

[0046] figure 2 Experimental Example 1 of the present invention is the tensile test curve of the negative pole sheet made in the present invention. In order to make the test more accurate, the tensile test curves of three sample batteries prepared by the above method are shown in the figure.

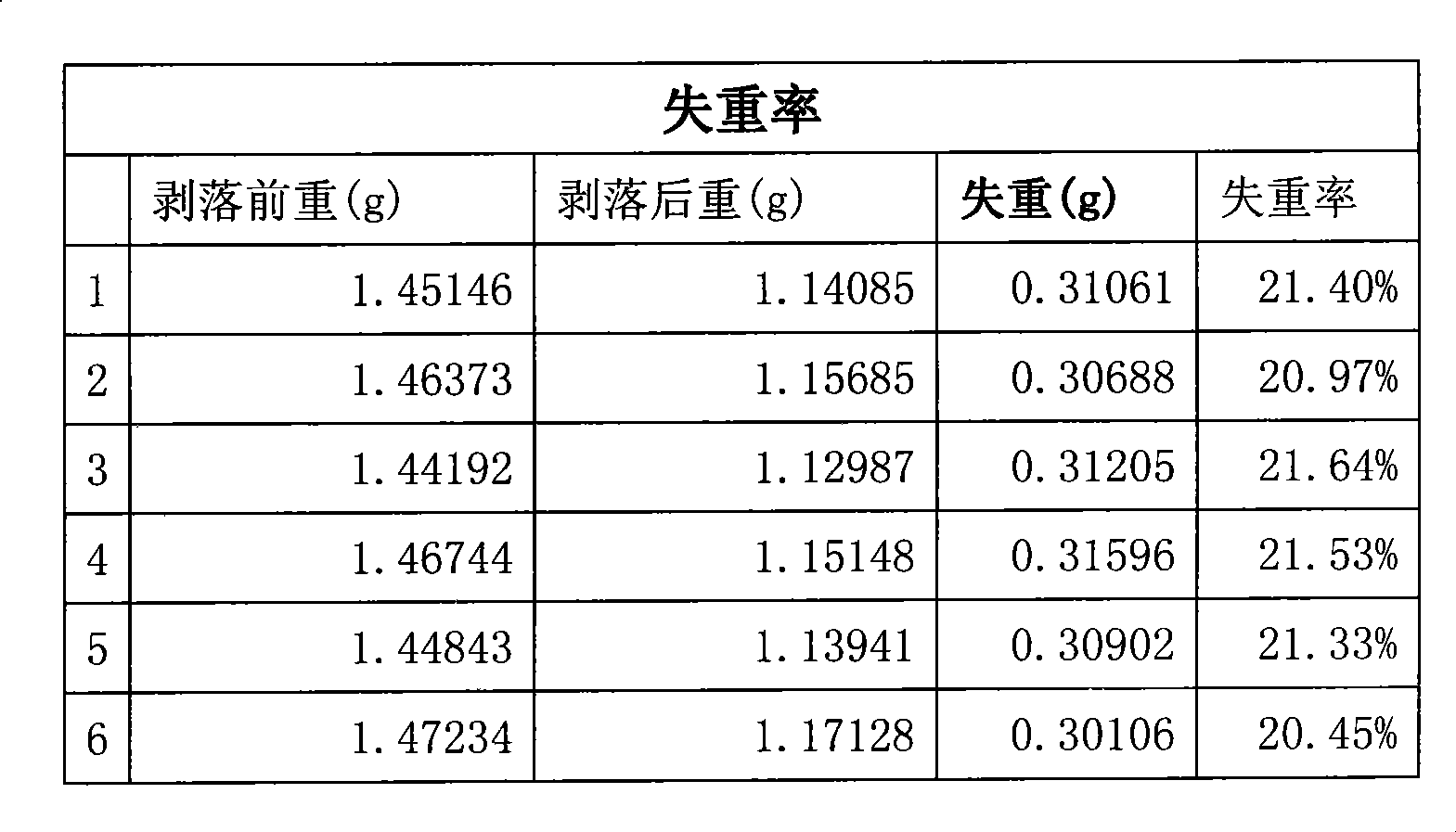

[0047] image 3 It is the weight loss rate data of the negative electrode sheet made in ...

experiment example 2

[0049] Adhesive ratio:

[0050] Oleic acid styrene butadiene rubber: rosin styrene butadiene rubber: plasticizer: white oil: antioxidant: solvent = 16: 12: 1.9: 1.4: 0.65: 95

[0051] Proportion of negative electrode slurry:

[0052] FSN-1 (graphite): SFG-6 (conductive agent): SBR (adhesive): CMC: solvent = 99:2:4:1:92

[0053] The test results of the negative electrode sheet and the battery prepared according to the method of the above embodiment: the capacity retention rate after 100 cycles was 96.78%, the maximum pulling force in the pulling test was 0.393 Newton, and the weight loss rate of the electrode sheet was 20.14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com