Method for integrally connecting retaining plate to wall of vacuum-cleaner filter bag, and vacuum-cleaner filter bag

A technology for holding plates and filter bags, applied in vacuum cleaners, suction filters, applications, etc., can solve problems such as no longer available energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

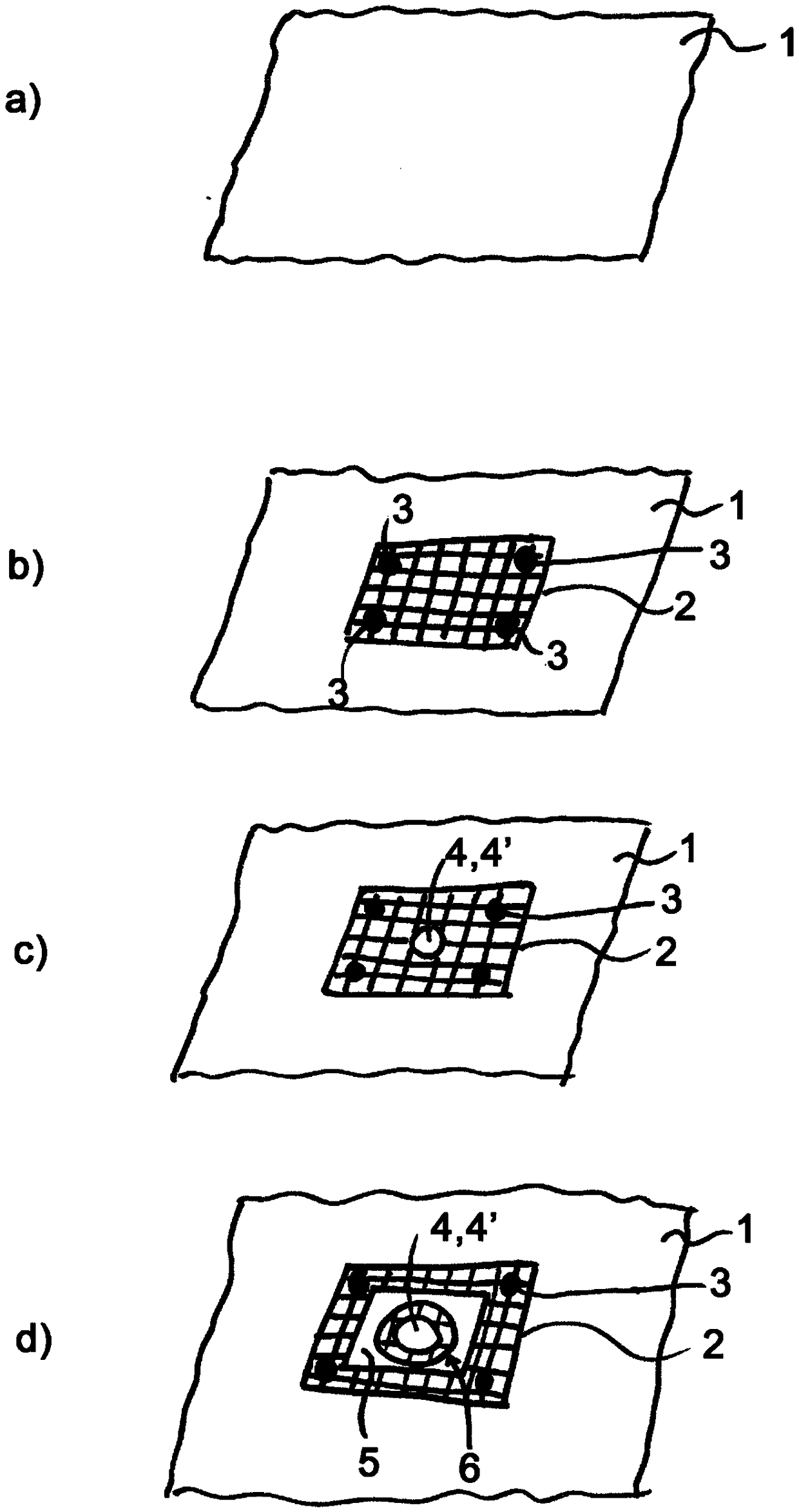

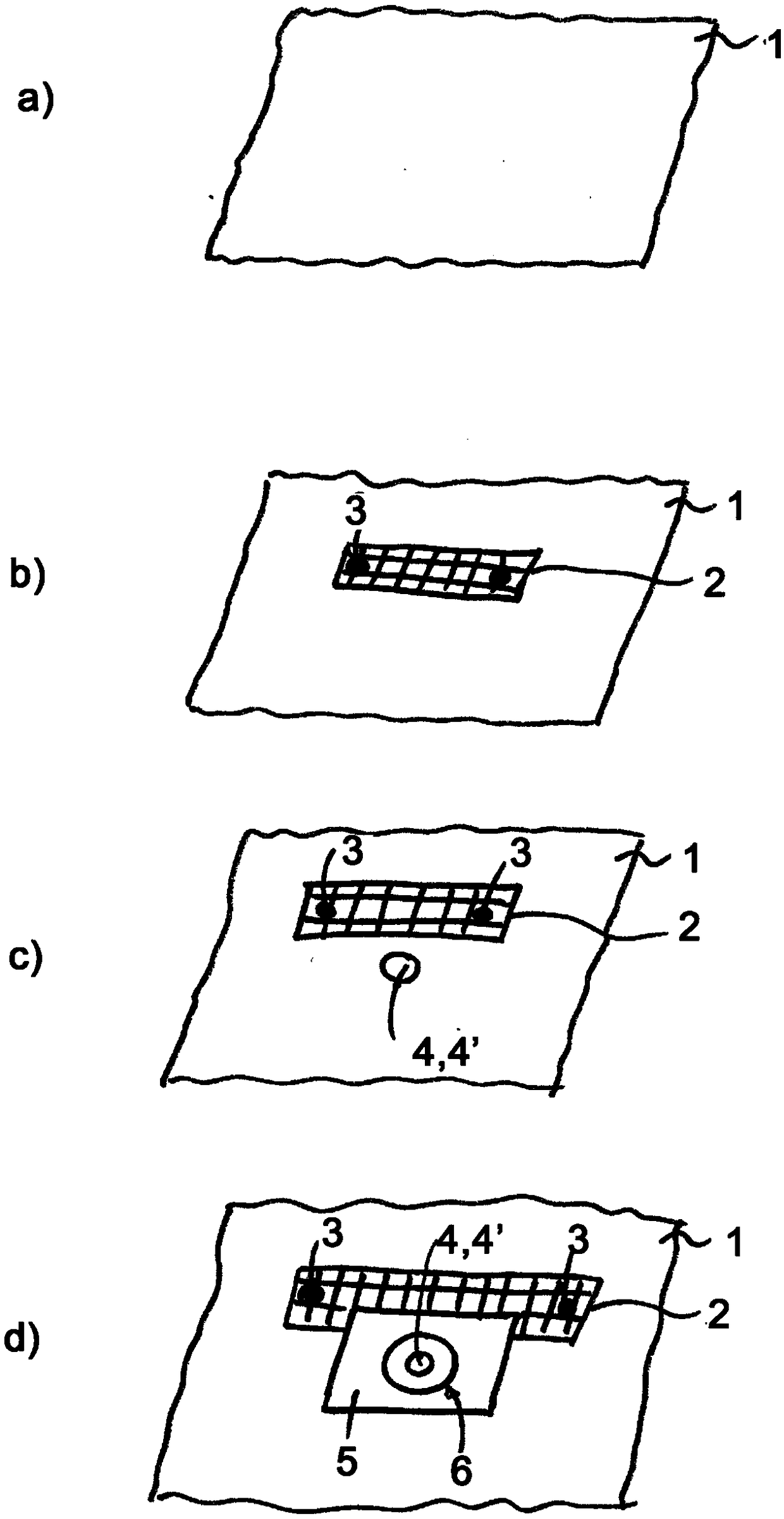

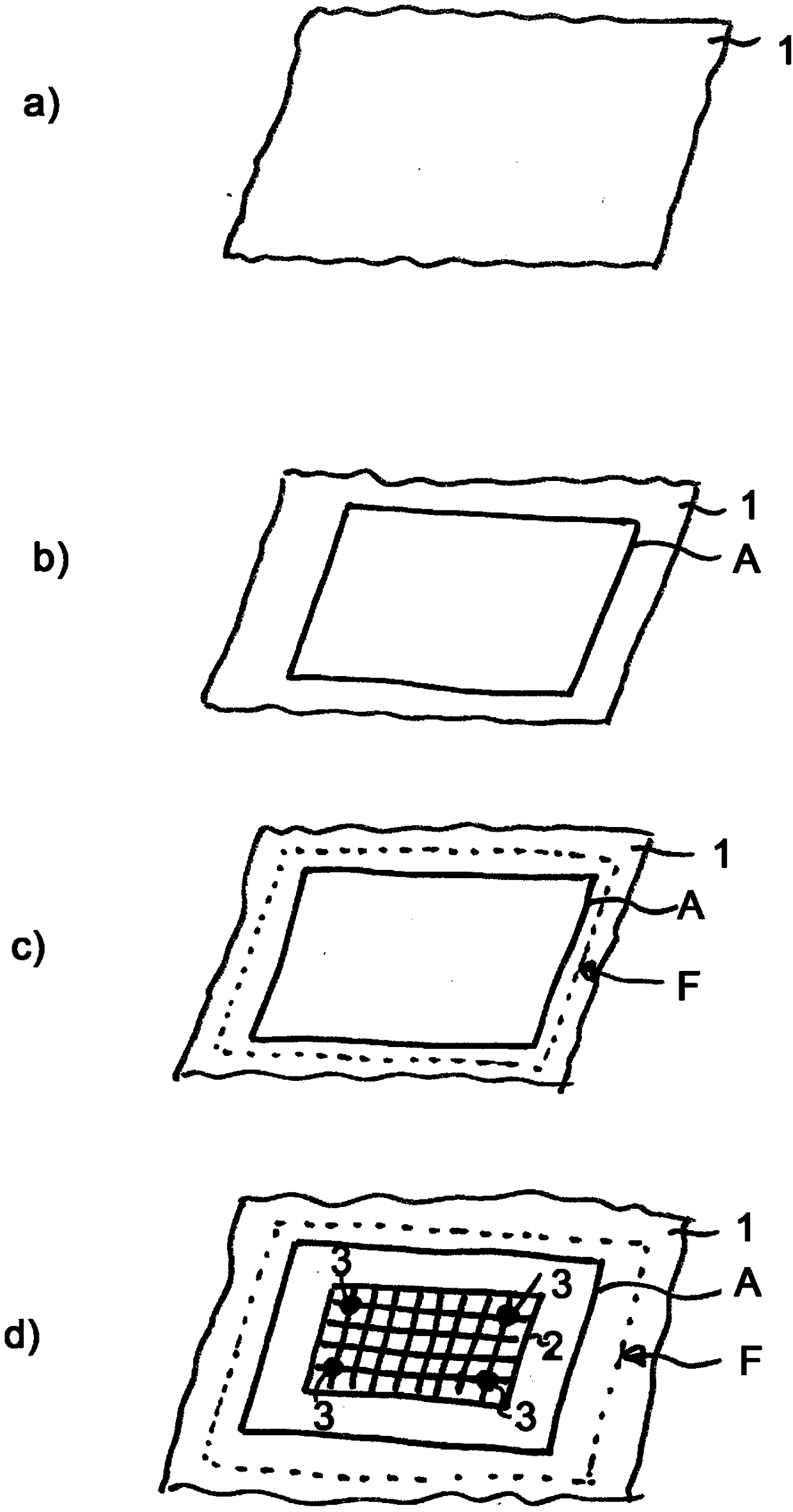

[0093] figure 1 A first method according to the invention for producing an inventive wall with inlet openings for a vacuum cleaner filter bag is shown. In the first step, the first step in figure 1 In a) it is shown that the wall 1 of the vacuum cleaner filter bag is provided. The wall can here be, for example, a non-woven material or a film. Likewise, laminates consisting of nonwoven materials or films are conceivable. The material may, for example, be supplied from a roll and unrolled continuously. exist figure 1 In a) (and in all subsequent figures) only a small detail of the material of the wall 1 of the vacuum cleaner filter bag is shown.

[0094] figure 1 b) shows the state after the textile material 2 has been applied to the side of the wall 1 of the vacuum cleaner filter bag by means of four separate individual welding points 3 . The remaining surface of the textile material 2 is loose here and is not connected to the wall of the filter bag. As an alternative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com