Novel MS sealant for fabricated concrete and preparation method thereof

A technology of MS sealant and concrete, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of large proportion of MS sealant, colloid thickness and positional deviation displacement, and low bonding strength of sealant. , to achieve the effect of excellent heat aging fixed elongation retention time, high tensile strength and maximum tensile force, and excellent tensile bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

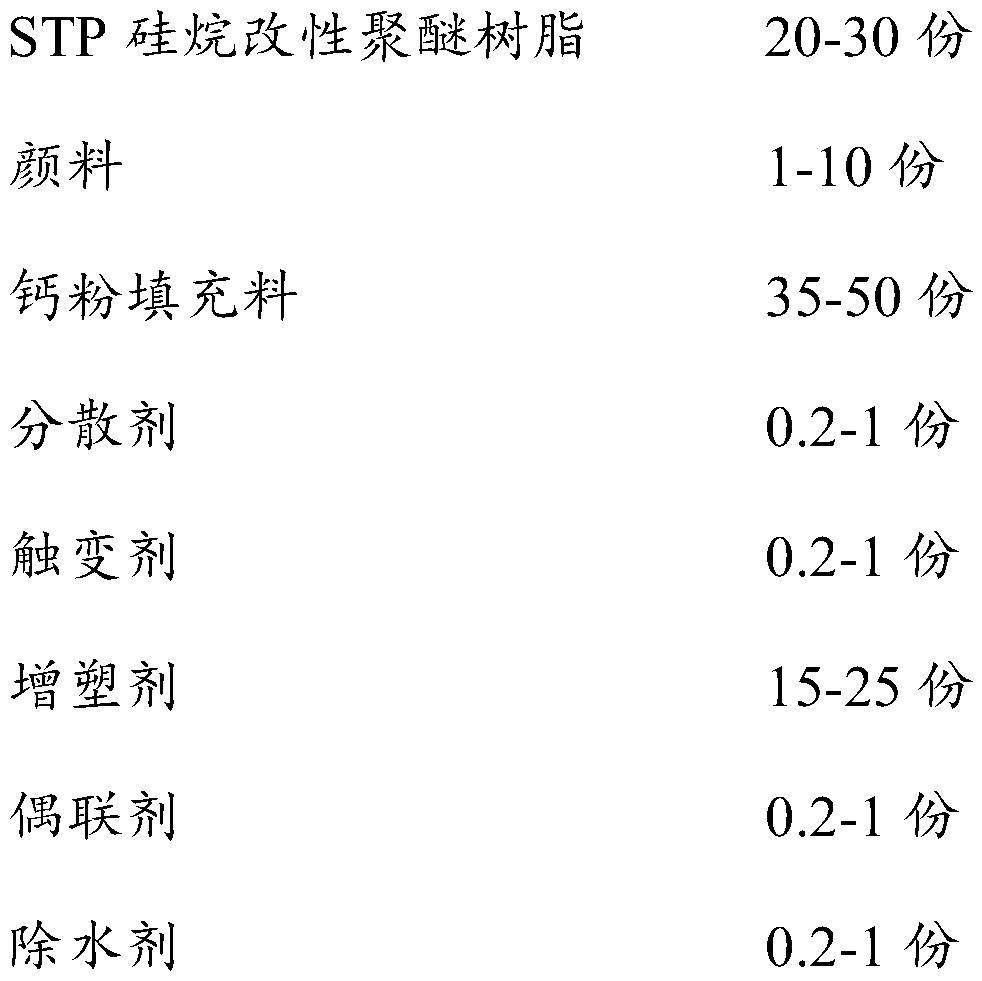

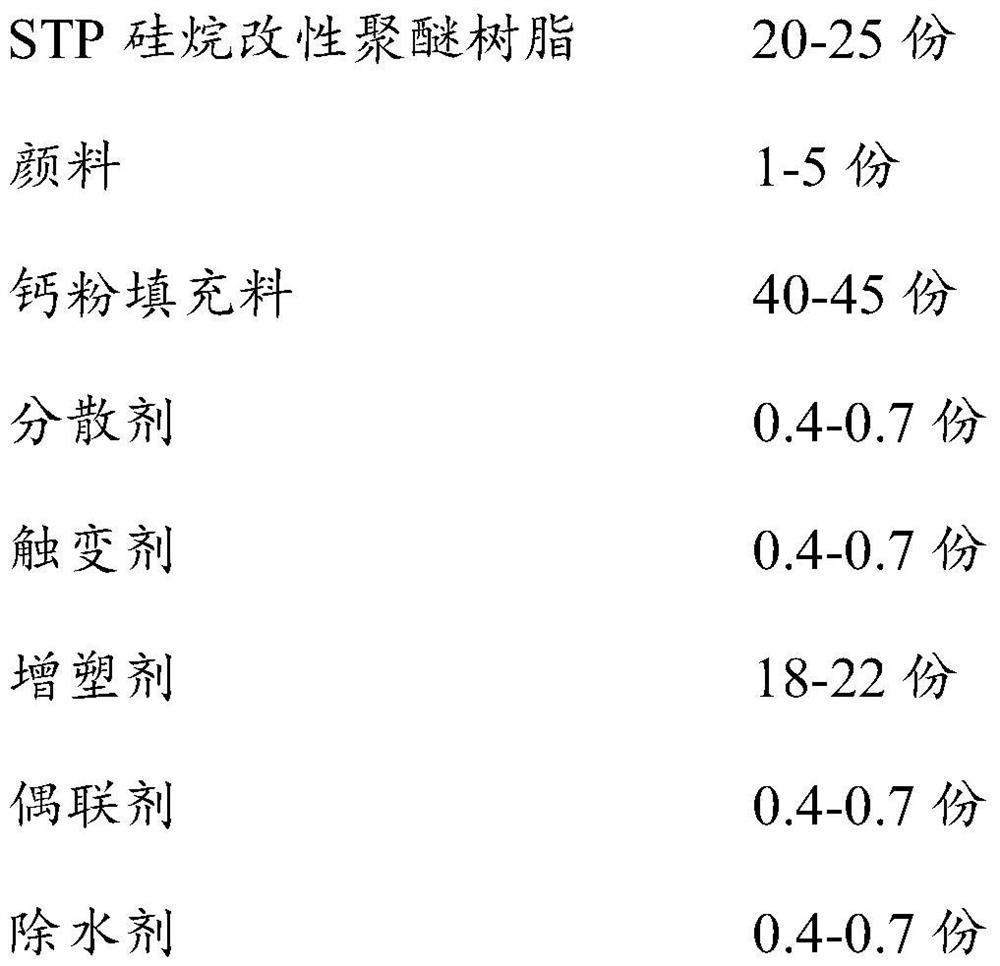

Method used

Image

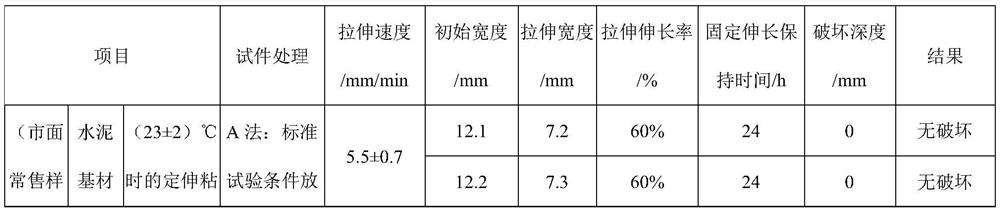

Examples

Embodiment 1

[0035] 25 parts of STP silane-modified polyether resin, 5 parts of pigment, 45 parts of calcium powder filler, 0.6 part of dispersant, 0.6 part of thixotropic agent, 22.6 parts of plasticizer, 0.6 part of coupling agent, and 0.6 part of water-removing agent.

[0036] Among them, the STP silane-modified polyether resin is selected from Jiangsu Ruiyang Antai New Material Technology Co., Ltd., and the product grade is 30000T.

[0037] Among them, the pigments include carbon black and titanium dioxide.

[0038] Among them, the calcium powder filler is selected from Guangxi Hezhou Kelong Powder Co., Ltd., including 800 mesh heavy calcium carbonate and 1300 mesh light calcium carbonate. The ratio of heavy calcium carbonate and light calcium carbonate is 1:1.

[0039] Among them, the dispersant is a polymer polyamide dispersant selected from Guangzhou Core New Material Technology Co., Ltd., the product brand is DISPER S35, and the molecular weight is 6500.

[0040] The preparation m...

Embodiment 2

[0057] The difference between this embodiment and embodiment 1 is:

[0058] 23 parts of STP silane-modified polyether resin, 10 parts of pigment, 45 parts of calcium powder filler, 0.3 part of dispersant, 0.7 part of thixotropic agent, 20 parts of plasticizer, 0.5 part of coupling agent, and 0.5 part of water remover.

[0059] The dispersant is a high-molecular polyamide dispersant, selected from Guangzhou Core New Material Technology Co., Ltd., the product brand is DISPER S9500, and the molecular weight is 15,000.

[0060] The thixotropic agent is a powdered polyamide thixotropic agent selected from Guangzhou Core New Material Technology Co., Ltd., and the product brand is PAMID D520.

[0061] The plasticizer is dioctyl phthalate.

[0062] The preparation method of this example differs from Example 1 in that: in step (2), adjust the co-rotating disc and the gear disc to disperse and stir at 10 Hz; Continue to stir and disperse for 1 hour under the same conditions; in step (...

Embodiment 3

[0064] The difference between this embodiment and embodiment 1 is:

[0065] 30 parts of STP silane-modified polyether resin, 1 part of pigment, 50 parts of calcium powder filler, 1 part of dispersant, 1 part of thixotropic agent, 25 parts of plasticizer, 1 part of coupling agent, and 1 part of water remover.

[0066] The dispersant is a polymer polyamide dispersant, selected from Guangzhou Core New Material Technology Co., Ltd., the product brand is DISPER S9300, and the molecular weight is 16000.

[0067] The thixotropic agent is a powdered polyamide thixotropic agent selected from Guangzhou Core New Material Technology Co., Ltd., and the product brand is PAMID D580.

[0068] The preparation method of this example differs from Example 1 in that: in step (2), adjust the co-rotating disc and the gear disc to disperse and stir at 20 Hz; Continue to stir and disperse for 2 hours under the same conditions; in step (4), adjust the revolving disk and gear disk to 20Hz, turn on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com