Peristaltic pump head

A peristaltic pump and pump head technology, applied in the field of pump components, can solve the problems of manual removal of the pressure tube card, laborious disassembly and assembly, low work efficiency, etc., and achieve faster and more labor-saving disassembly and assembly, wide applicability, and labor-saving disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

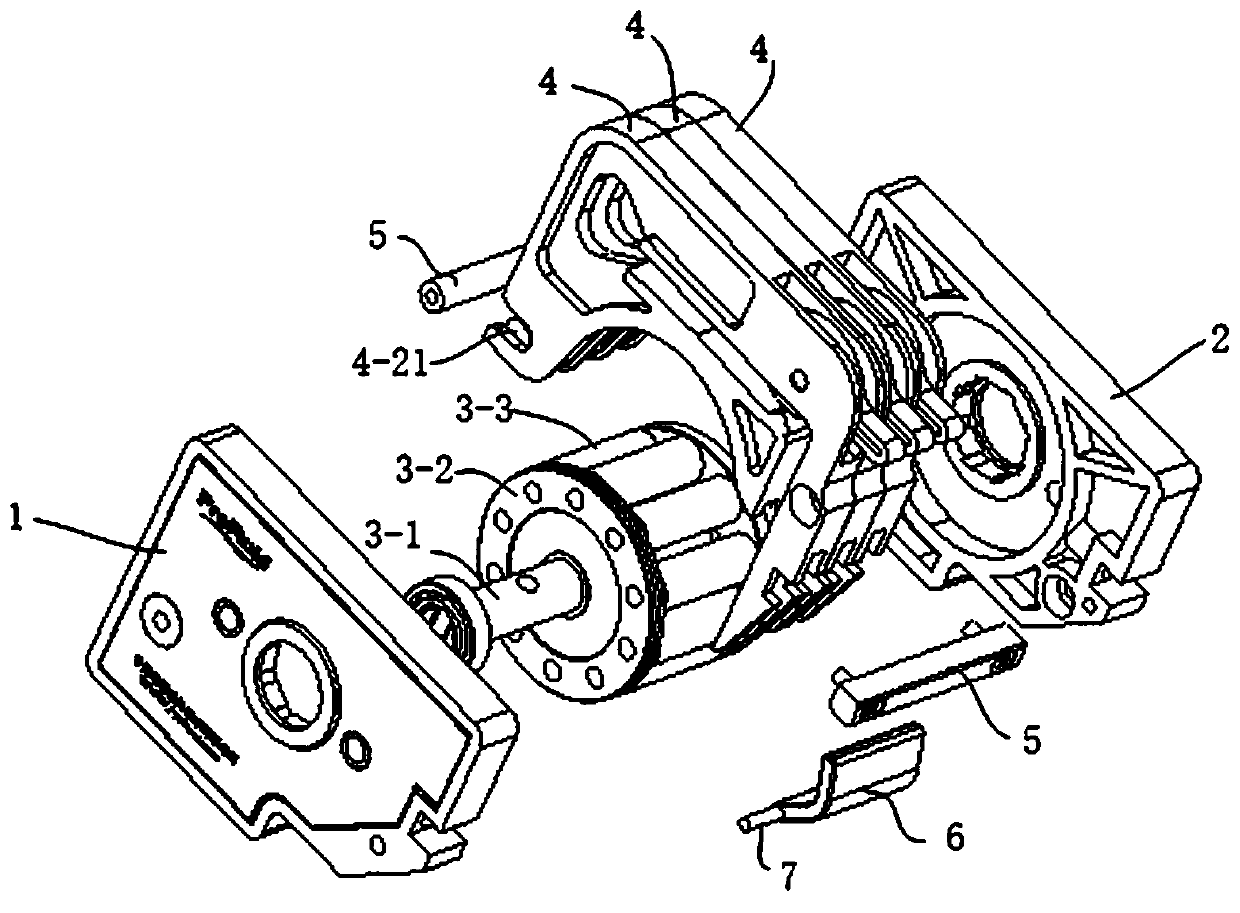

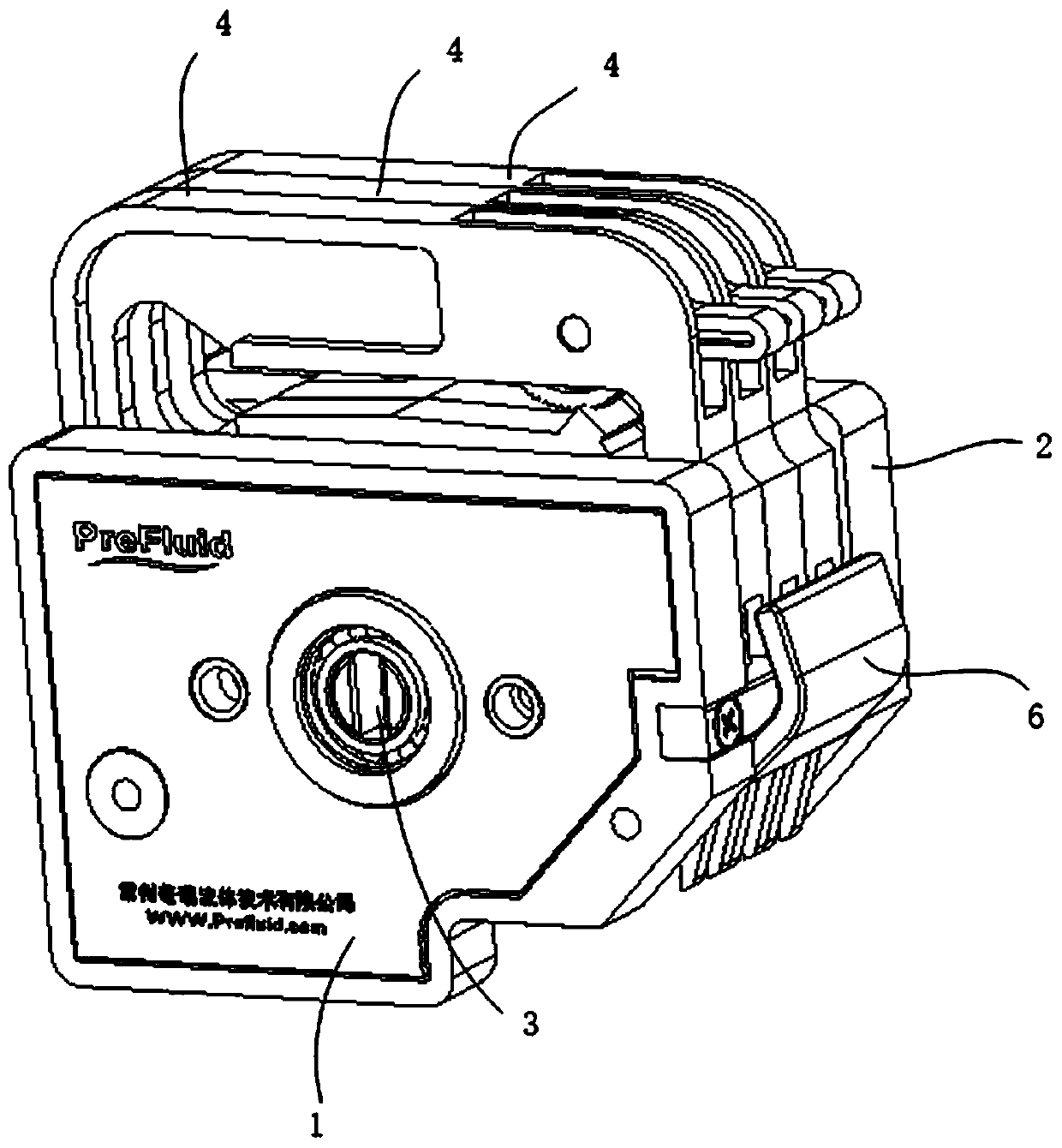

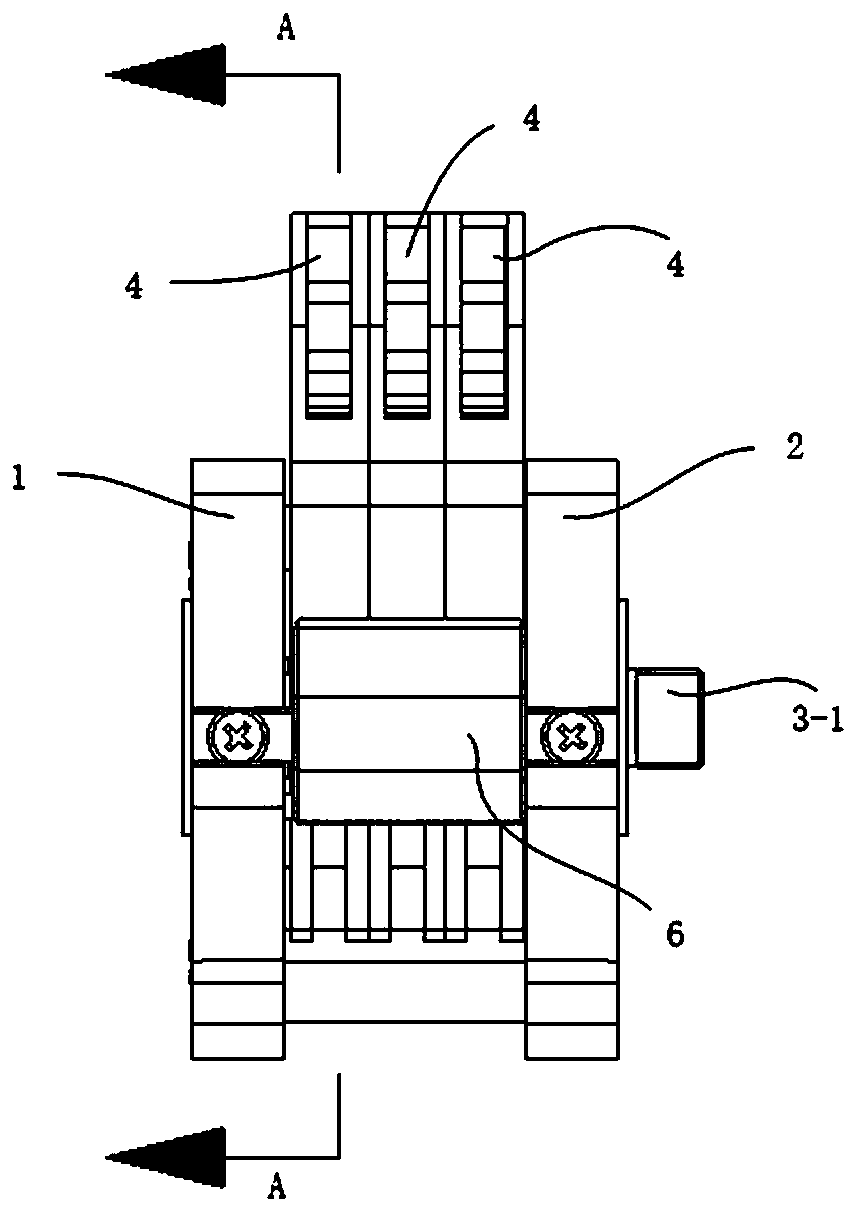

[0035] Example 1, such as Figure 1-Figure 3 As shown, a peristaltic pump head includes a front baffle 1, a rear baffle 2 and a roller assembly 3, the front and rear ends of the roller assembly 3 are respectively rotatably connected to the front baffle 1 and the rear baffle 2, and the roller assembly 3 includes The rotating shaft 3-1 and the roller group sleeved on the rotating shaft 3-1, the roller group includes a roller bracket 3-2 and a roller 3-3, and the roller bracket 3-2 is arranged in a circular array with the rotating shaft 3-1 as the center There are a plurality of mandrels 3-4, and each mandrel 3-4 is sleeved with a roller 3-3. There are three pressure tube cards 4 between the front baffle 1 and the rear baffle 2. The pressure tube cards 4 include a fixed part 4-2 and a pressure tube part 4-1. The elastic hose is located between the pressure tube part 4-1 and the roller. Between 3-3, fixed side arms are arranged on both sides of the fixed part 4-2, which is a door...

Embodiment 2

[0038] Embodiment 2, on the basis of Embodiment 1, the side of the fixed side arm in contact with the wrench 6 is an inclined plane, and the inclined plane gradually inclines to the inner side of the fixed part 4-2 from top to bottom; when the fixed side arm is clamped When on the support column 5, the upper surface of one end of the wrench 6 is pressed into contact with the inclined plane, and the other end of the wrench 6 is against the support column 5 (such as Figure 4 As shown), that is, the wrench 6 is set on the top to prevent the wrench 6 from occupying the connection space of the protruding elastic hose; when the wrench 6 is rotated downward, the fixed side arm is separated from the support column 5, and the end of the wrench 6 close to the fixed side arm The upper part is a raised arc-shaped structure, and the upper surface of the end of the wrench 6 is a plane, and the distance from the outer edge of the raised arc-shaped structure to the wrench pin 7 is greater tha...

Embodiment 3

[0039] Example 3, such as Image 6 with Figure 7 As shown, on the basis of Embodiment 1 or Embodiment 2, the pressure tube card 4 also includes a ratchet 4-3, and the outer ring of the ratchet 4-3 is provided with a ratchet 4-31; the ratchet 4-31 of the ratchet 4-3 Usually one-way teeth (such as Figure 9 Shown in the enlarged area), it is more labor-saving to turn the ratchet 4-3 when pressing the pressing tube part 4-1. The ratchet 4-3 is movably connected with the fixed part 4-2, one end of the pressure tube part 4-1 is a fixed end, and the other end is a movable end, the fixed end is fixed with the fixed part 4-2, and the movable end is connected with the ratchet 4 -31 fit, the pressure tube part 4-1 is located inside the fixed part 4-2, and the lower surface of the pressure tube part 4-1 is a concave arc-shaped surface, corresponding to the arc-shaped upper surface structure of the roller assembly 3 . The ratchet 4-3 is located above the pressing tube part 4-1, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com