Mechanical sealing device

A technology of mechanical sealing device and bellows, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of poor spring automatic compensation ability, long spring length, and poor axial recovery ability of spring, etc., to achieve extended service life , reduce torque and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

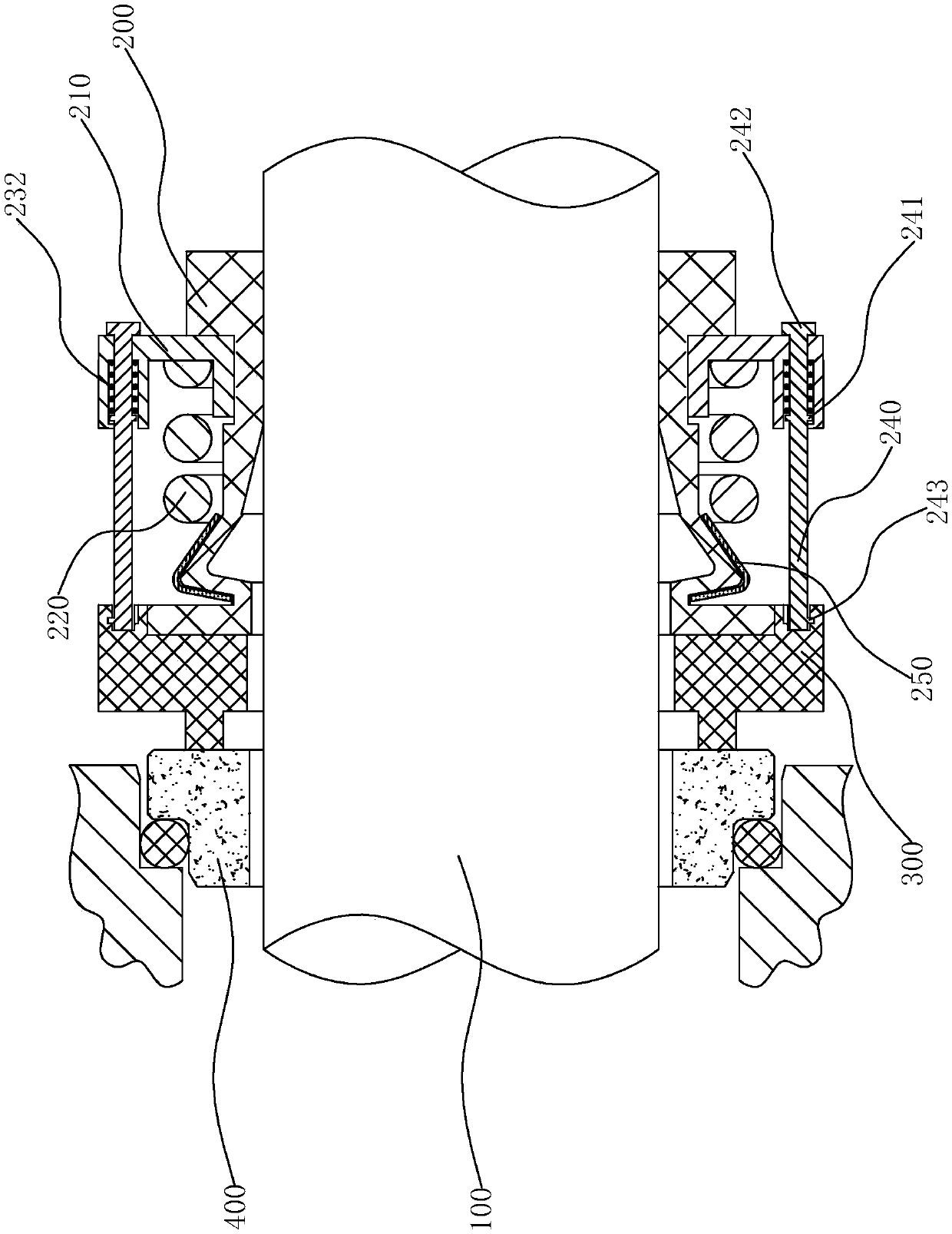

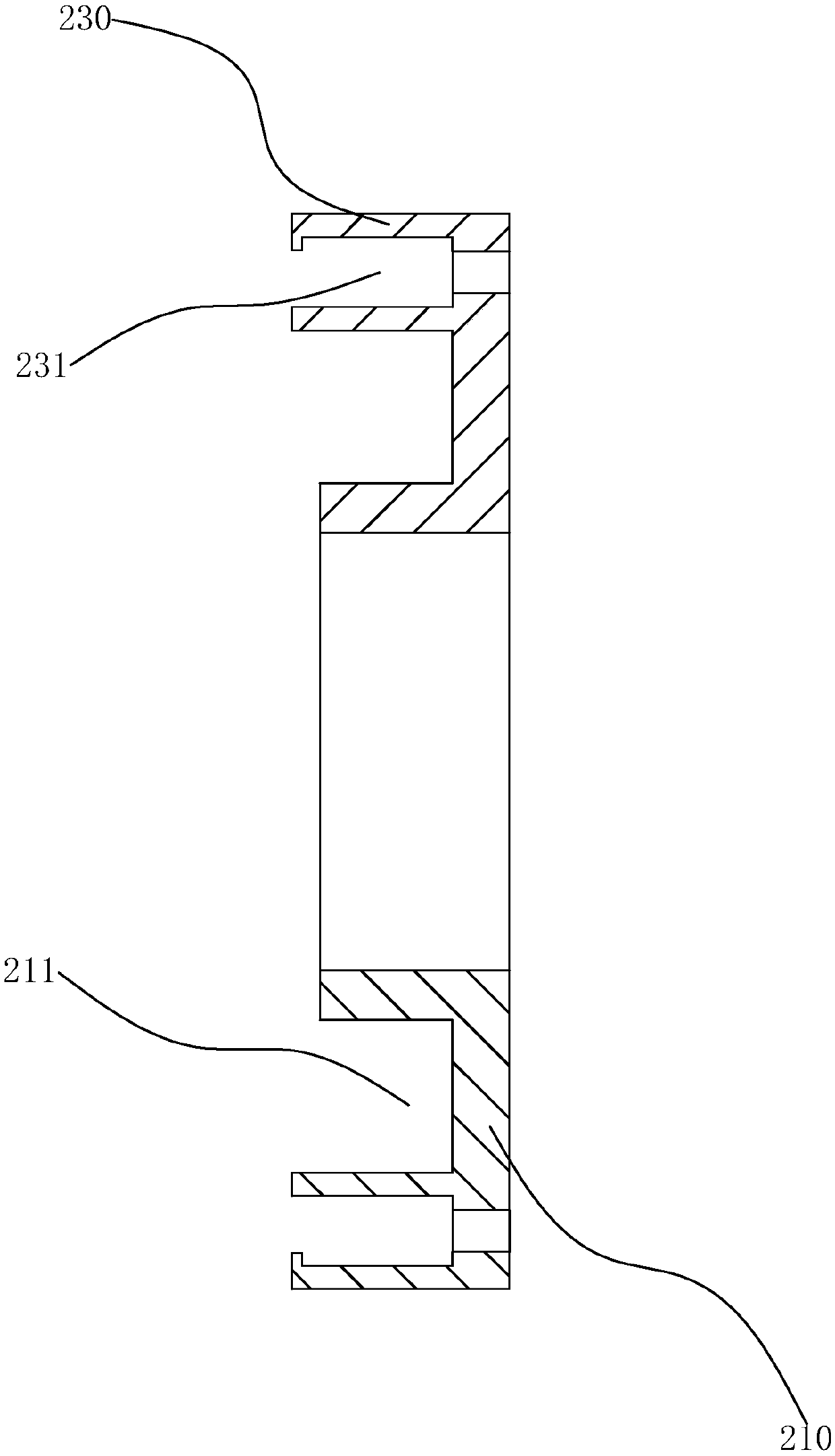

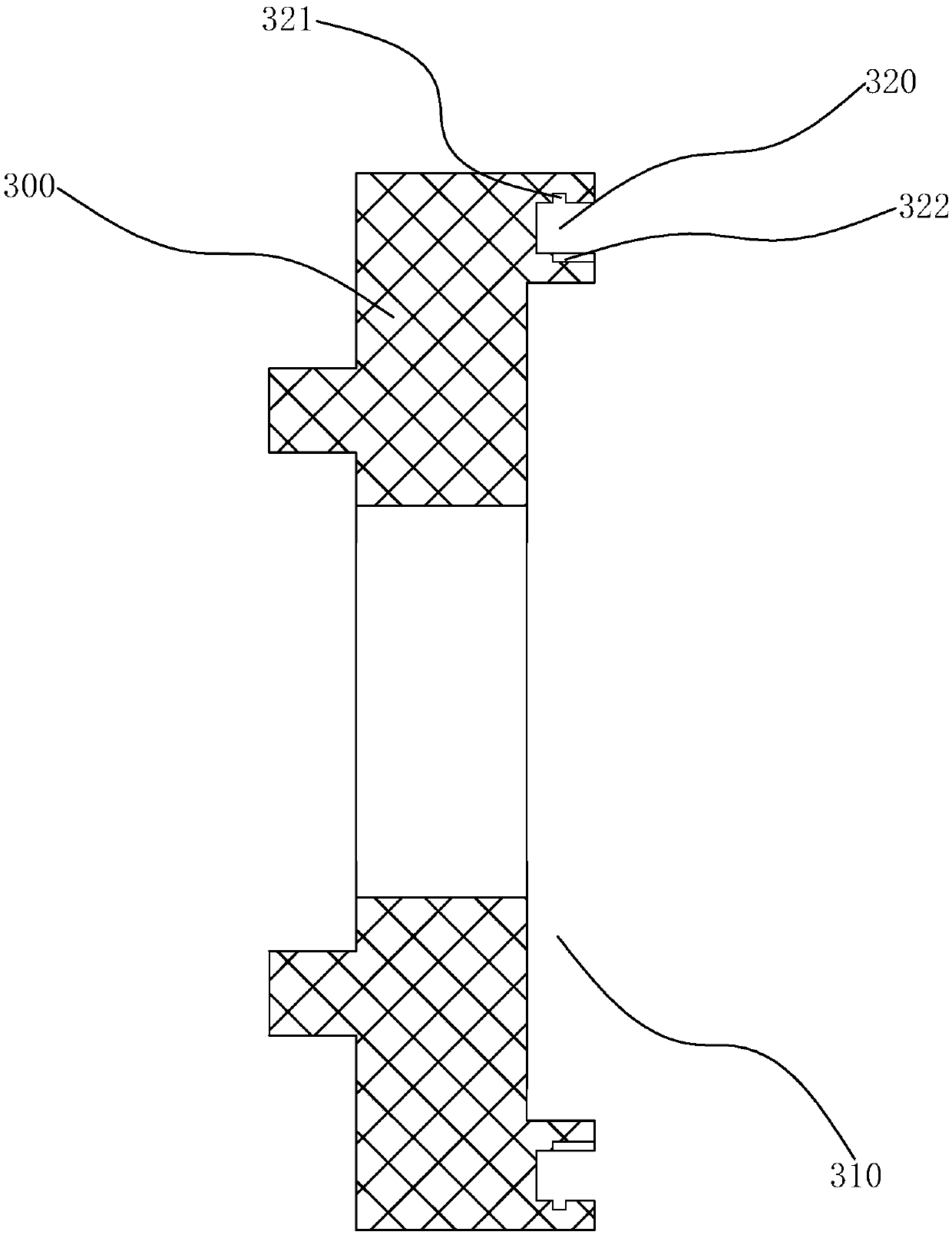

[0017] Such as figure 1 As shown, a mechanical sealing device of the present invention includes a rotating shaft 100 and a bellows 200 arranged on the rotating shaft 100, a moving ring 300, and a static ring 400. The rear end of the bellows 200 is attached to the front end of the moving ring 300. The rear end of the moving ring 300 is attached to the static ring 400 and rotates on the static ring 400. The bellows 200 is provided with a spring seat 210, and the spring seat 210 is axially provided with a first annular groove 211 and the first The spring 220 is located in the first annular groove 211, and two symmetrical guide cylinders 230 are axially arranged on the outer edge of the spring seat 210. The guide cylinder 230 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com