Self-positioning resistance repairing fixture

A self-positioning and resistance repairing technology, applied in resistors, resistance manufacturing, liquid/fluid solid measurement, etc., can solve the problems of path deviation, high product scrap rate, large positioning error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

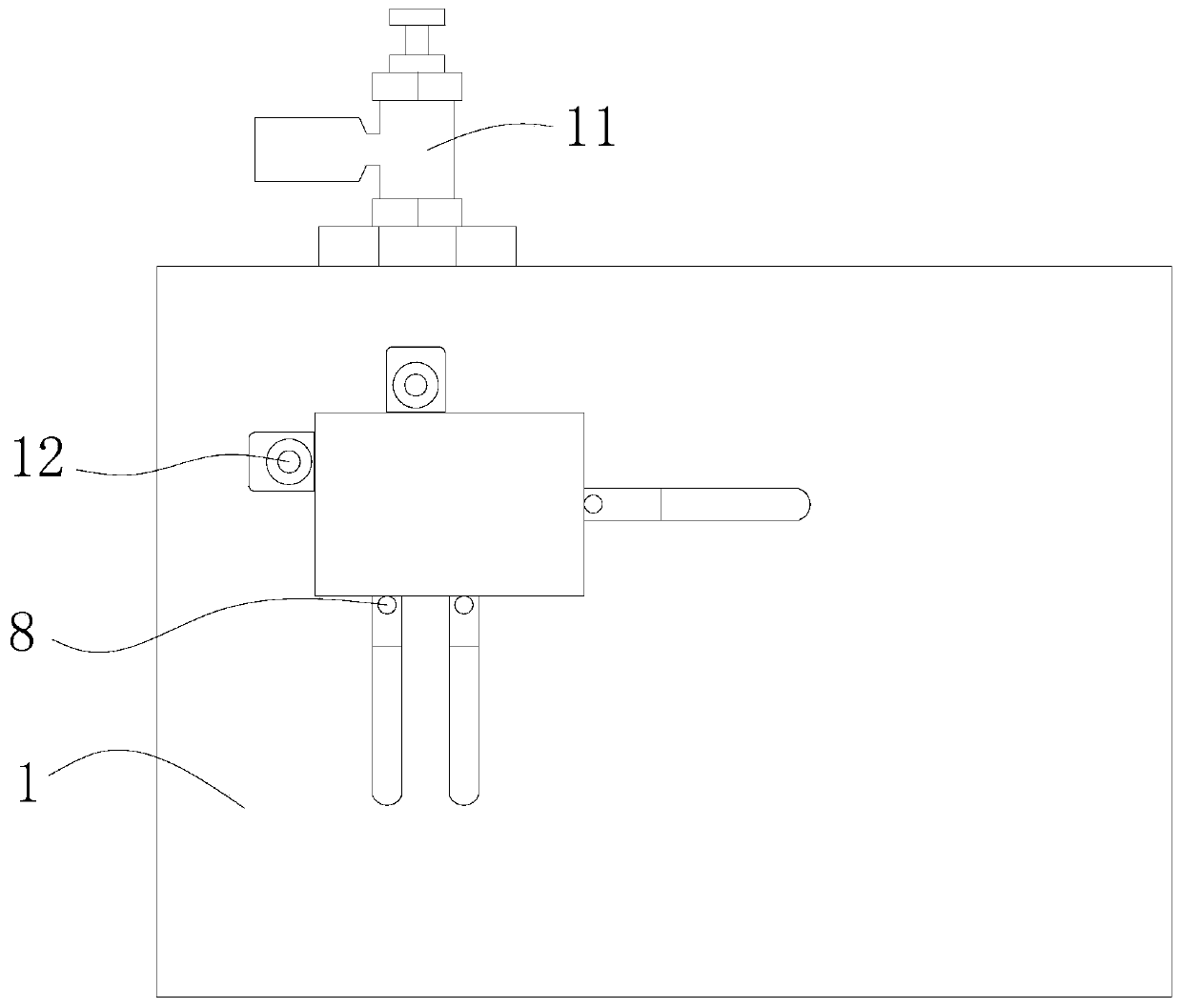

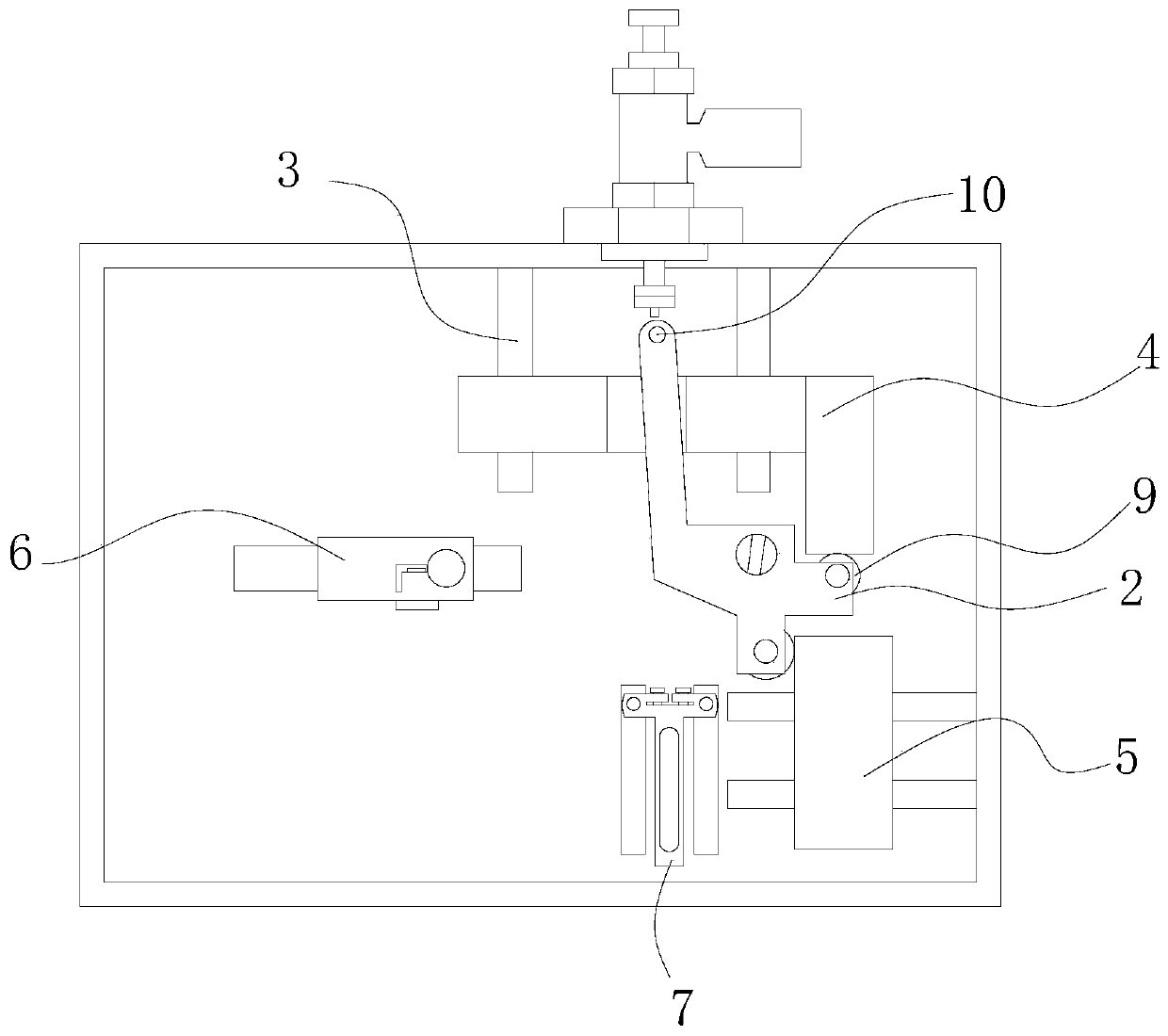

[0018] see Figure 1-2 , a self-positioning resistance repair fixture,.

[0019] When in use, place the chip that needs to be retrogradely repaired in the area surrounded by the limiting column and the second rotating shaft. After the chip is placed, after the first correction, when the chip is repositioned, slide the second After a fixed block 6 or the second fixed block 7 supports the chip, at this time, as the first fixed block 6 or the second fixed block 7 transmits the force to the second rotating shaft 12 through the chip when the chip is pushed, the second rotating shaft 12 moves under the condition of force, and drives the first moving block 4 or the second moving block 5 to move on the slide bar 3 through the second rotating shaft 12. As the first moving block 4 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com