Modularized six-freedom-degree precision inching mechanism based on flexible hinge

A flexible hinge, modular technology, applied in the parts, instruments and other directions of the instrument, can solve problems such as wear and tear, and achieve the effect of avoiding motion errors, compact mechanism, and increasing motion reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

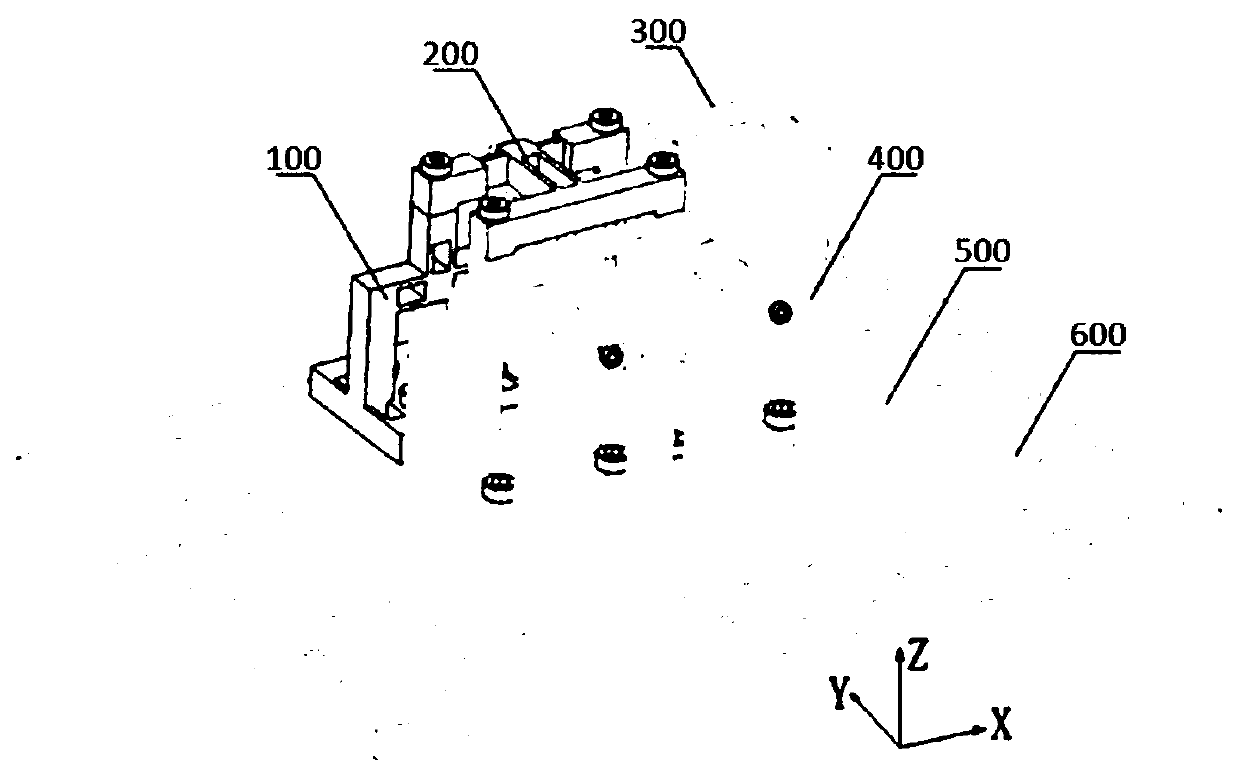

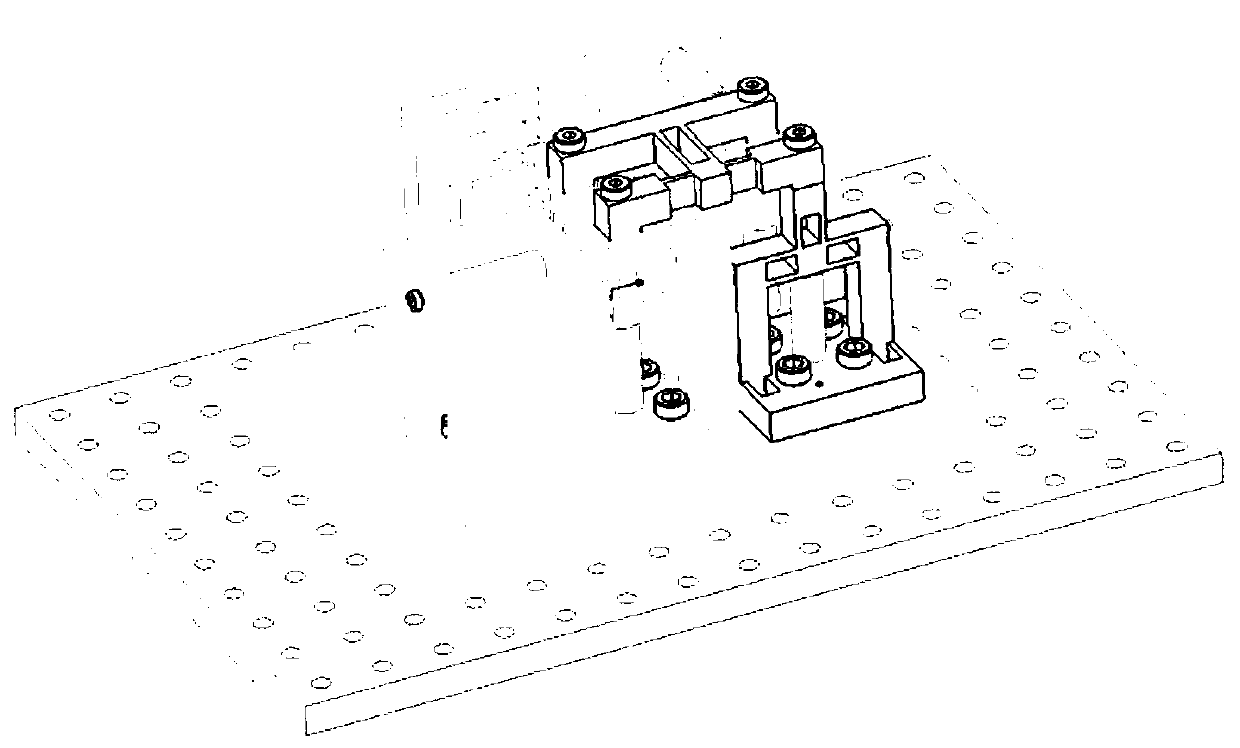

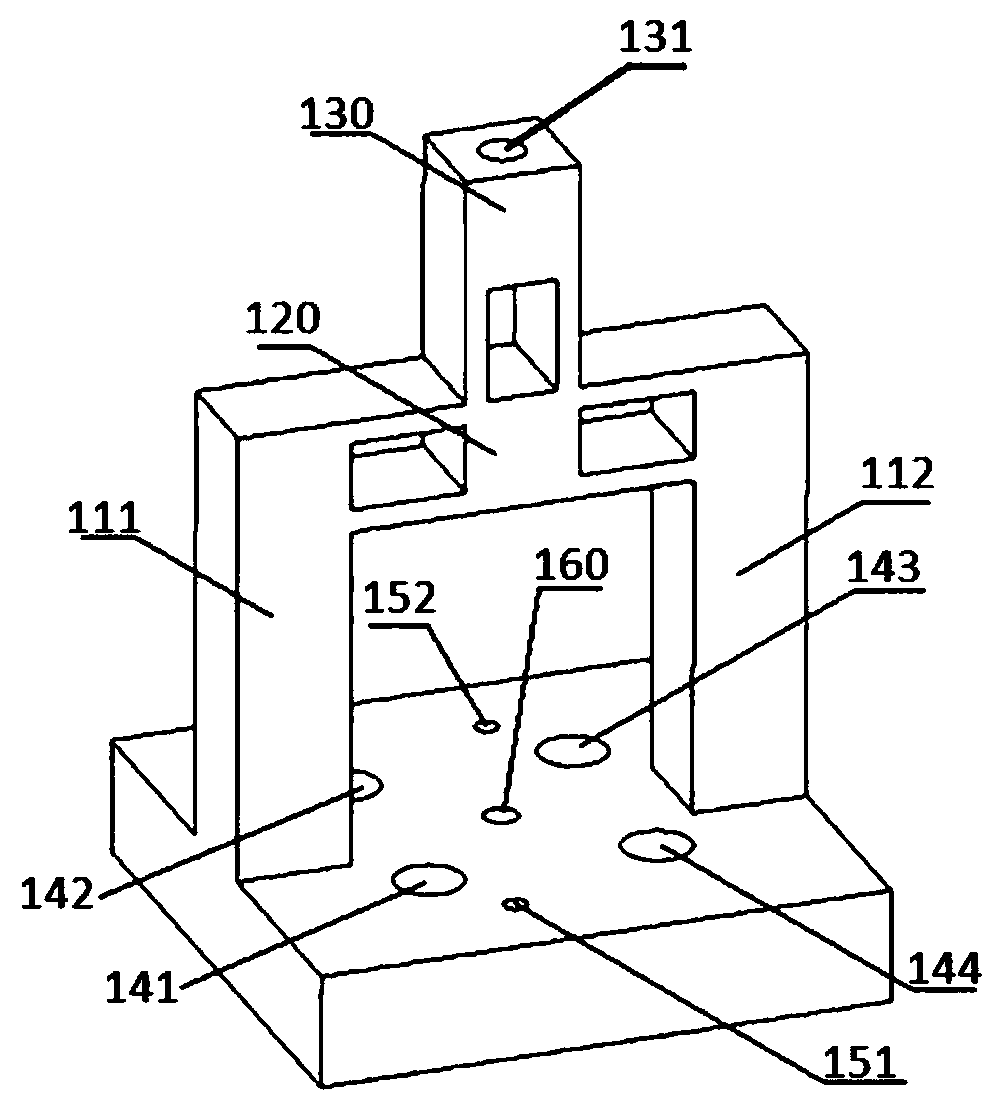

[0079] Such as figure 1 As shown, the present invention provides a modular six-degree-of-freedom precision micro-motion mechanism based on flexible hinges, and its main structure includes a first original drive block 100, an output frame 200, a second original drive block 300, and a third original drive block 400, fixed panel 500, installation panel 600; the fixed panel 500 is fixed and detachable installed on the installation panel 600; the first original drive block 100 is detachably installed on the fixed panel 500; wherein, the first original drive block 100 includes A plurality of first vertical support frames 111, 112, a first direct drive block 120 flexibly connected between the first vertical support frames 111, 112 and a first output block 130 flexibly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com