Steel pipe for steel plate and line pipe and manufacturing method thereof

A manufacturing method and technology for steel plates, which can be applied to manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as uncontrollable bubble size, uncompressed bubbles, and insufficient suppression of HIC, and achieve excellent resistance to hydrogen-induced cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

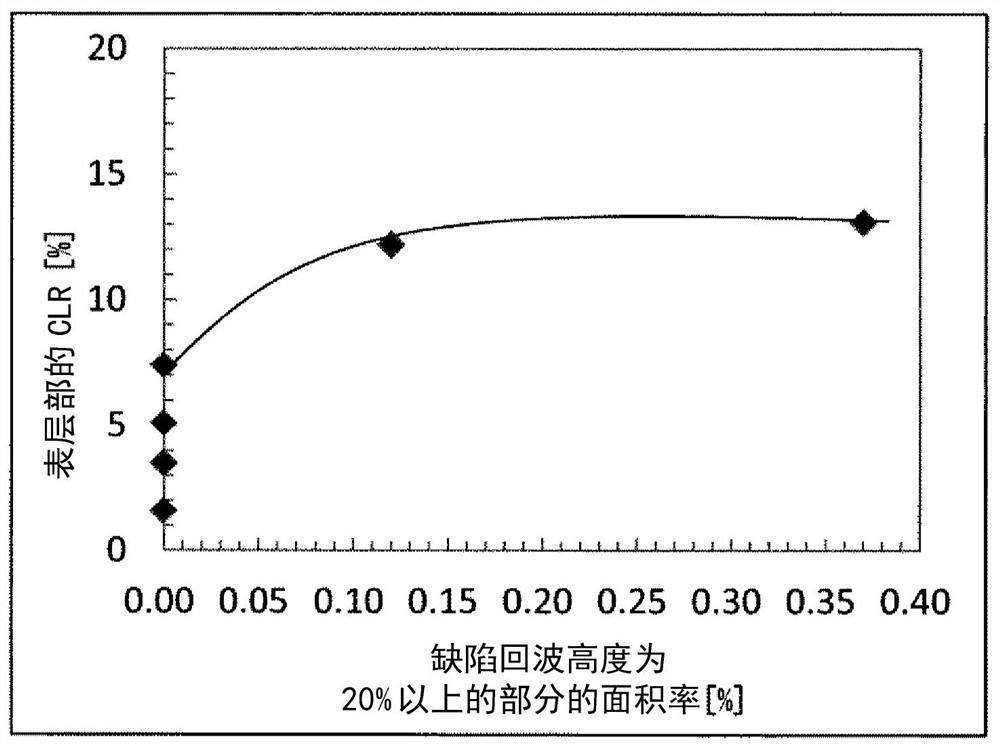

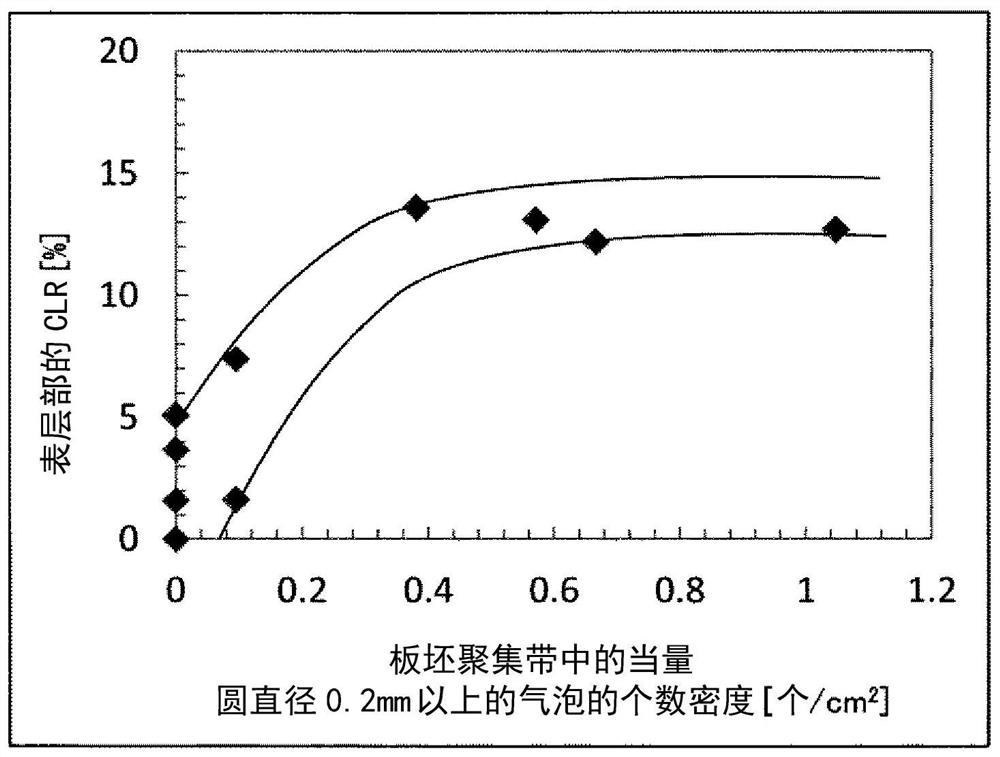

[0024] In order to solve the above-mentioned problems, the present inventors compared the CLR (ClackLength Ratio, the ratio of the total crack length to the width of the test piece [%], the crack length ratio) of the surface layer measured by the HIC test with that measured by the ultrasonic flaw detection test. The inter-correlation of the internal defects of the steel plate was intensively studied. As a result, it was found that the chemical composition of the steel plate is controlled within a specified range so that the contents of Ca, S, and O satisfy a specified relational expression, and the area ratio of the portion with a defect echo height of 20% or more is 0.05% or less. By controlling internal defects, excellent HIC resistance can be obtained.

[0025] Hereinafter, the steel plate according to the embodiment of the present invention and its manufacturing method will be described in detail.

[0026]

[0027] (1-1. Chemical Composition)

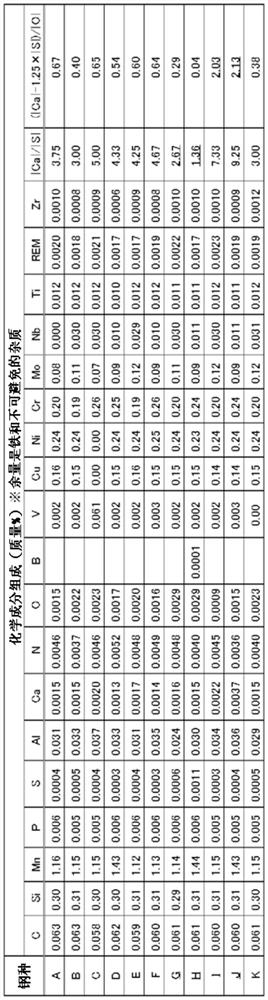

[0028] The steel plate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com