Straight row tree whitening machine

A whitening machine and in-line technology, which is applied in the field of tree whitening, can solve the problems of insufficient smearing and low efficiency of artificial whitening, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0045] This embodiment is the embodiment of straight tree whitening machine.

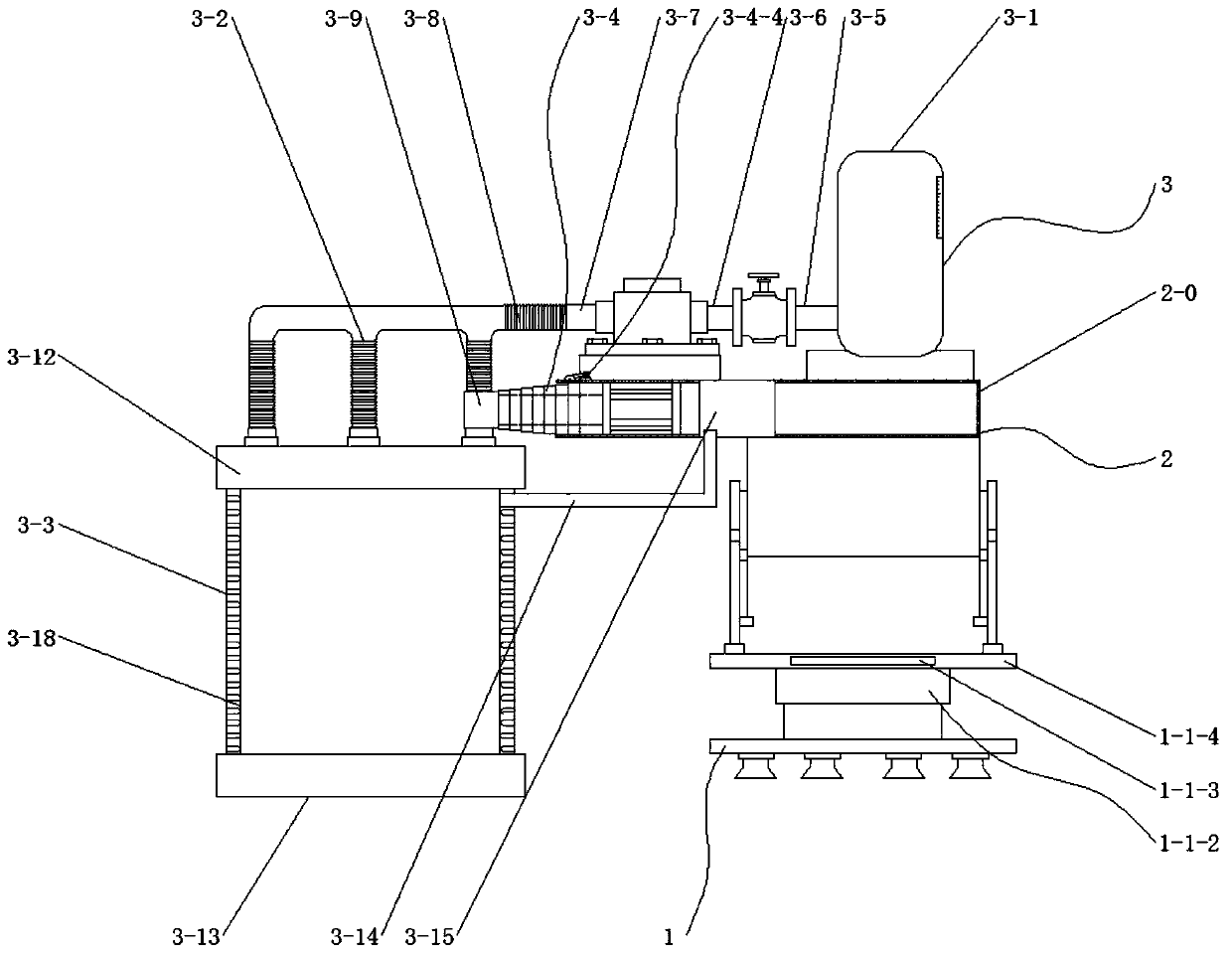

[0046] The straight tree whitening machine of the present embodiment comprises track 1, moving device 2 and whitening device 3; The upper end of described track 1 is provided with moving device 2, and the upper end of described moving device 2 is fixedly connected with whitening device 3 ;

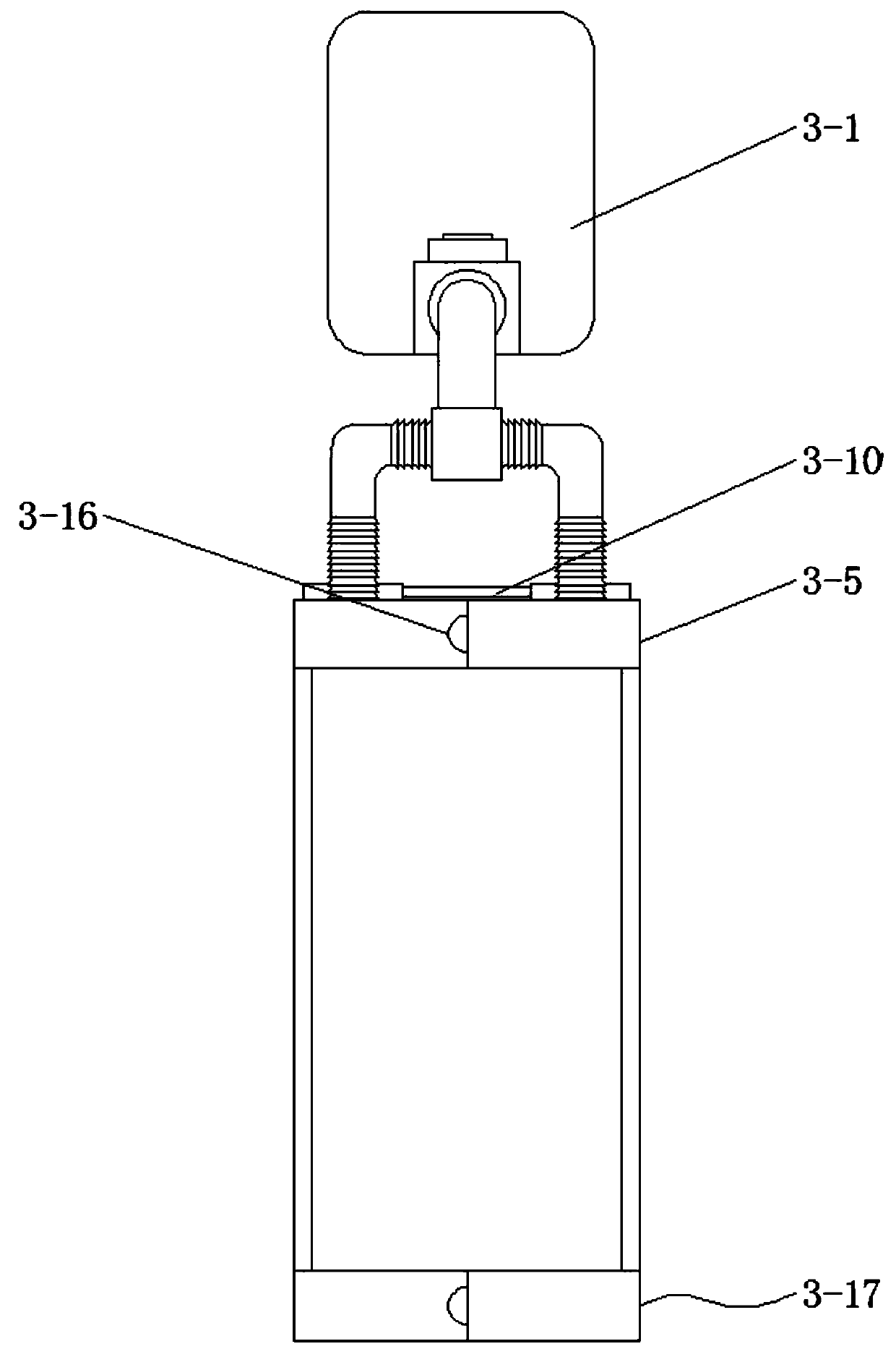

[0047] The whitening device 3 includes a paint box 3-1, a sub-hose 3-2, a first filling film 3-3 and an extension device 3-4; the upper end of the moving device 2 is provided with a paint rack, and the paint The upper end of the frame is provided with a paint box 3-1, and one side of the paint box 3-1 is processed with a discharge spiral through hole, and the discharge spiral through hole is threadedly connected with the first discharge pipe 3-5. The first discharge pipe 3-5 communicates with one side of the switch valve, the other side of the switch valve communicates with one end of the second discharge pipe ...

specific Embodiment 2

[0049] This embodiment is an embodiment of a mobile device used for an in-line tree whitening machine.

[0050] The mobile device used for the straight row tree whitening machine of this embodiment can exist independently as a component of the straight row tree whitening machine, and can further limit the straight row tree whitening machine described in the first embodiment .

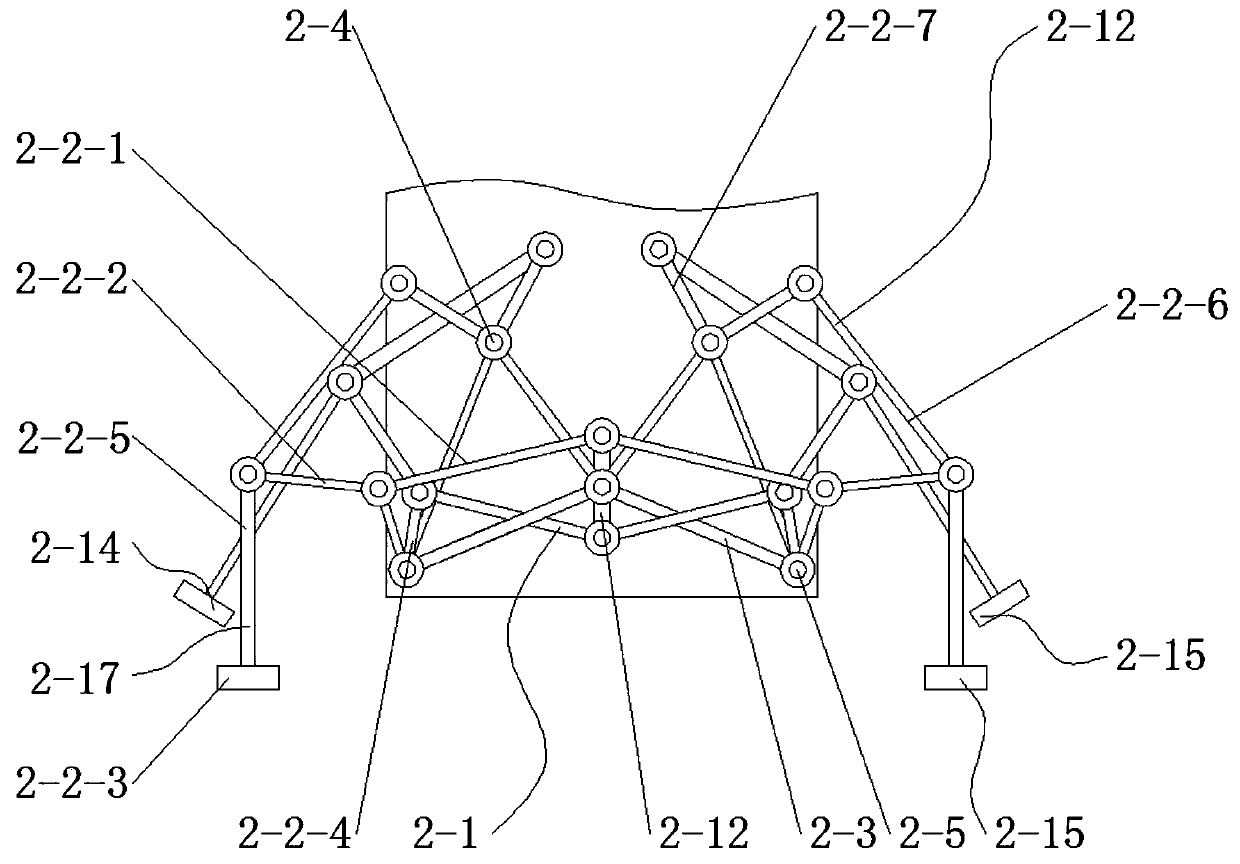

[0051]The above-mentioned inline tree whitening machine, on the basis of the specific embodiment one, is different in that the mobile device 2 includes a container 2-0, a mounting frame 2-1 and a total transmission device 2-2; the container 2- The lower end of 0 is provided with installation box, and the two sides of described installation box are respectively provided with two groups of installation frames 2-1, and two groups of described installation frames 2-1 are made up of two groups of described tripods 2-3, each group The first positioning end 2-4 and the second positioning end 2-5 of the two gr...

specific Embodiment 3

[0054] The above-mentioned in-line tree whitening machine, on the basis of the first specific embodiment, is different in that the track 1 includes a first track 1-1 and a second track 1-2, and the first track 1-1 includes a second track 1-1. A bottom frame 1-1-1, an adjustment device 1-1-2 and a connecting block 1-1-3; several groups of first suction cups are arranged at the lower end of the first bottom frame 1-1-1, and the first bottom The upper end of the frame 1-1-1 is provided with an adjustment device 1-1-2, and the upper end of the adjustment device 1-1-2 is provided with a first top plate 1-1-4, and the first top plate 1-1-4 The two ends are provided with connecting blocks 1-1-3;

[0055] The second track 1-2 includes a second underframe 1-2-1, an adjustment device 1-1-2 and a second top plate 1-2-2; the lower end of the second underframe 1-2-1 is set Several groups of second suction cups, the upper end of the second chassis 1-2-1 is provided with an adjustment devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com