Flexible switching method for laser deep penetration fusion welding and laser decorated welding

A deep penetration welding and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as poor effect and low welding efficiency, and achieve high production efficiency, high degree of automation, and flexible switching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

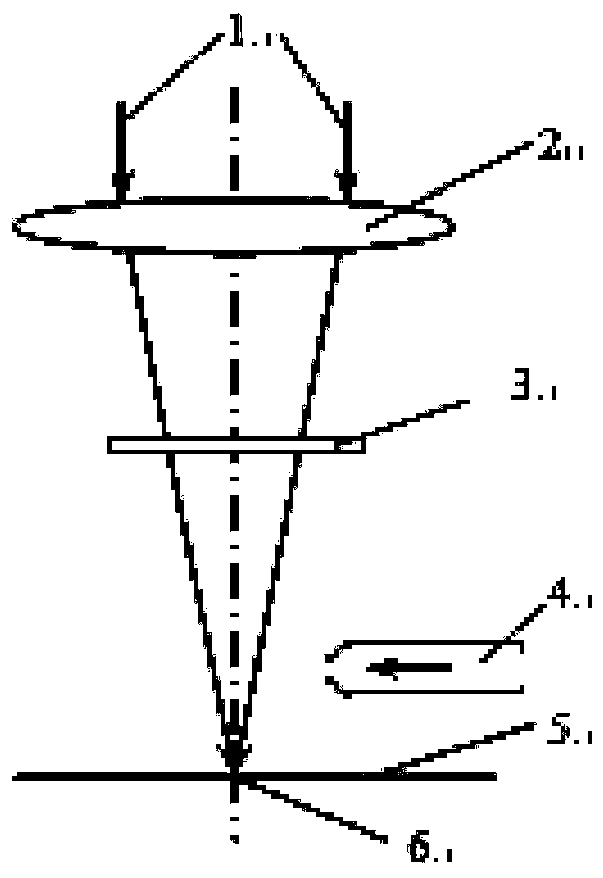

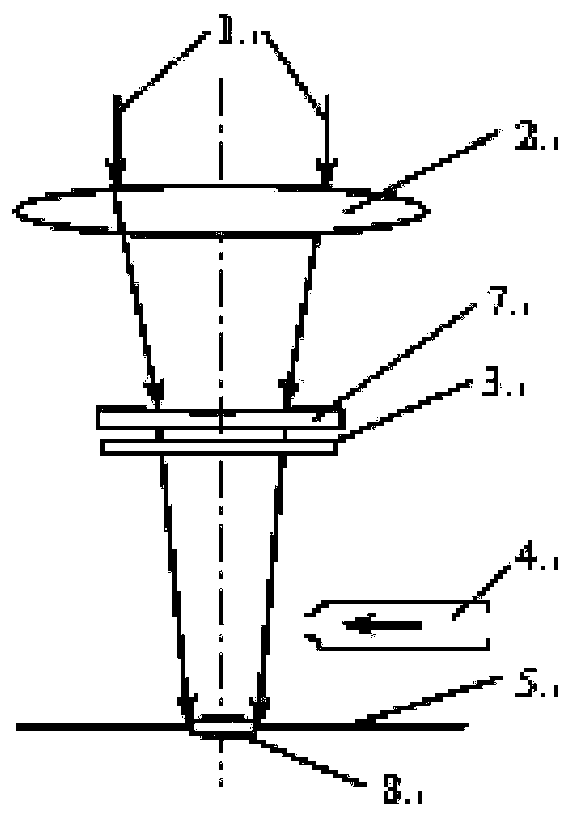

[0040] Example 1: see figure 2 with image 3 , a diffractive optical lens designed with a concave spherical surface is used for flexible switching between laser deep penetration welding and laser finishing welding, including the following steps:

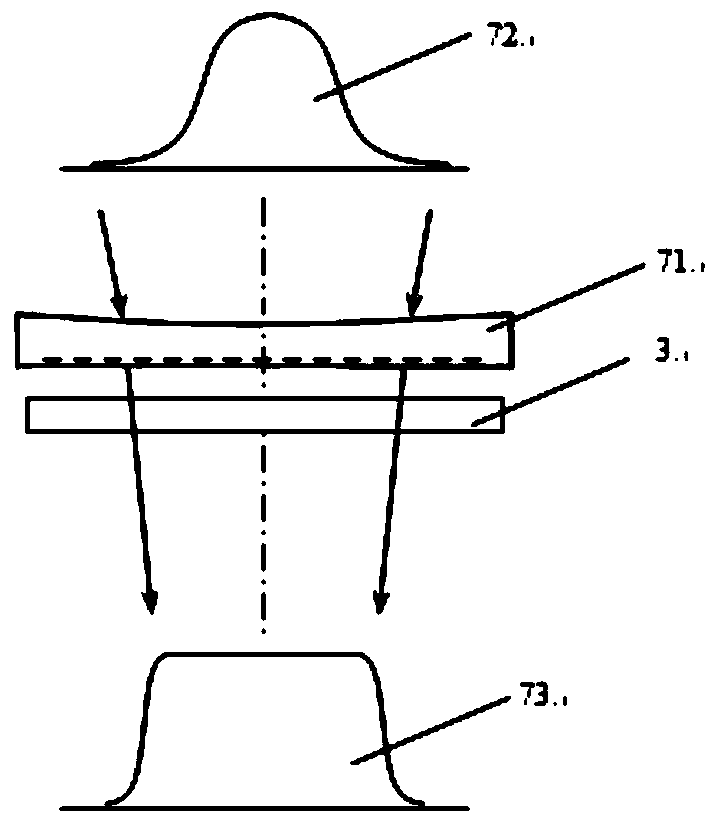

[0041] Step 1. Select a concave spherical diffractive optical lens 71 suitable for modifying the welding seam with a weld width of 2 mm to 3 mm. One side is a concave spherical surface, and the other side is a stepped or continuous relief structure. The concave spherical focal length of the concave spherical diffractive optical lens 71 is - 600mm.

[0042] Step 2. On the welding plane 5 of the metal structural parts, adopt the welding process parameters with a welding speed of not less than 6m / min, a laser power of not less than 4kW, and zero defocus. After the fiber laser deep penetration welding is completed, the weld surface is cleaned of welding spatter. In this step, the focal length of the focusing lens 2 during laser deep ...

Embodiment 2

[0046] Example 2: see figure 2 , Figure 4 , Figure 5 with Image 6 , using a double-cylindrical grooved diffractive optical lens for flexible switching between laser deep penetration welding and laser finishing welding, including the following steps:

[0047] Step 1. Select a diffractive optical lens 74 suitable for modifying the welding seam with a weld width of 5 mm to 6 mm. One side is a double-cylindrical groove, and the other side is a stepped or continuous relief structure. The radius R of the double-cylindrical surface is 600 mm, and the double-cylindrical The distance between the axes of the surfaces is 50mm.

[0048] Step 2. On the welding plane 5 of the metal structural parts, adopt welding process parameters with a welding speed of 1.0m / min to 2.0m / min, a laser power of 2kW to 3kW, and zero defocus. After the fiber laser deep penetration welding is completed, Remove weld spatter from weld surfaces. The focal length of the focusing lens 2 during laser deep pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com