Thermal insulation structure repairing method

A technology of radial size and position, applied in the field of thermal protection structure maintenance, can solve the problems of reducing the maintenance cycle and cost of hypersonic aircraft, and achieve the effect of shortening the maintenance cycle, good high temperature resistance and heat insulation performance, and avoiding secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

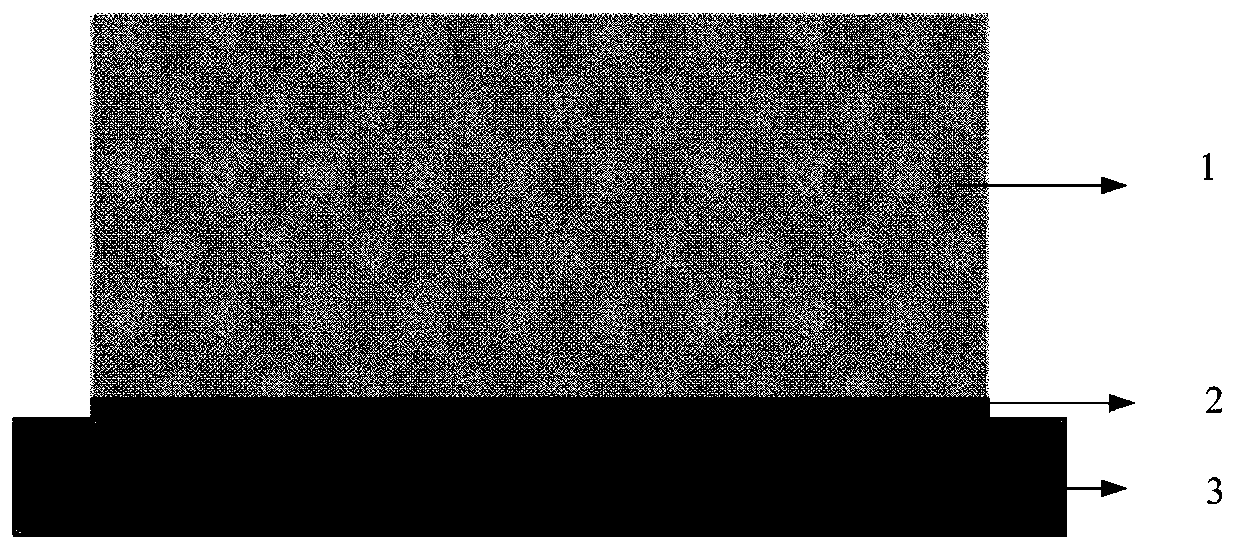

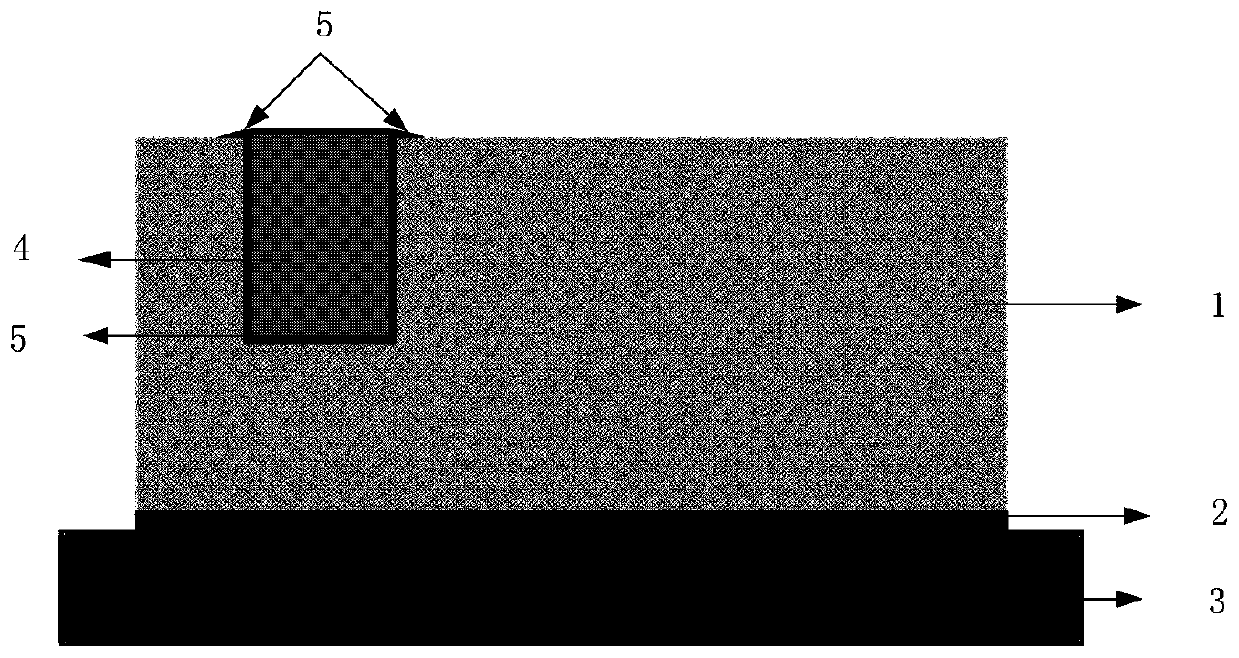

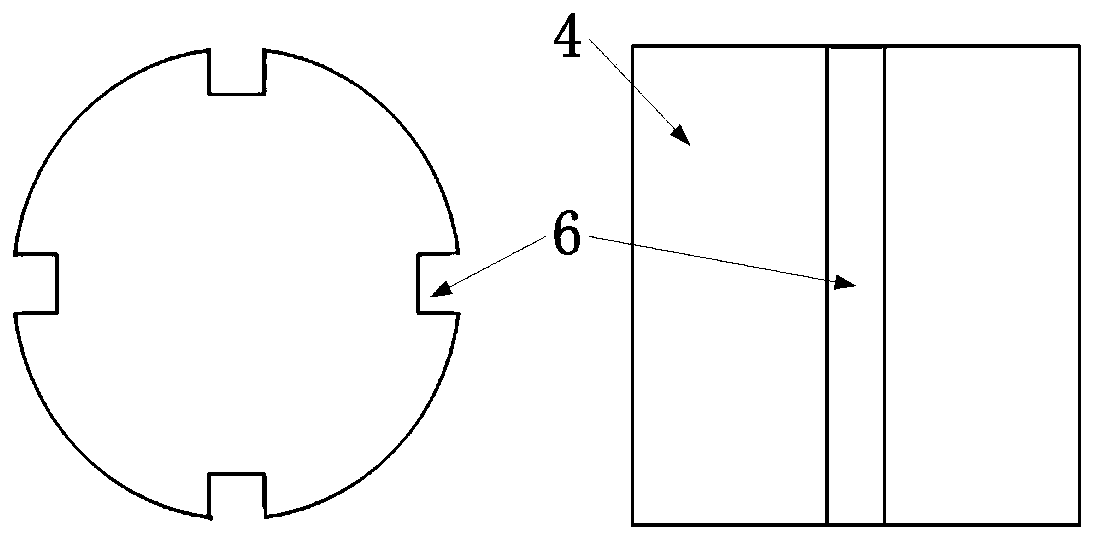

[0028] A method for repairing a heat insulation structure: processing the damaged part of the heat insulation structure, processing the irregular damaged part into a repair hole with a regular shape, and the processing method is low-speed processing, and the radial size of the repair hole is larger than that of the damaged part The radial dimension of the repair block is more than 5mm larger; process a repair block with a similar shape to the repair hole, and set n glue grooves in the longitudinal direction of the repair block; apply high temperature resistant adhesive evenly on the side and bottom of the repair block and all surfaces of the repair hole agent; place the repair block in the repair hole to ensure that the high-temperature-resistant adhesive can fill the gap between the repair block and the repair hole; after curing the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com