Inorganic flame retardant fireproof heat insulation tape and application thereof

An inorganic flame-retardant and heat-insulating tape technology, which is applied in fiber mechanical structures, cables, insulated conductors, etc., can solve the problems of secondary injury and poor heat insulation performance of fire rescue personnel, and achieve excellent fire resistance and high temperature resistance. and thermal insulation performance, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preparation of ultralong nanowires from hydroxyapatite. The hydroxyapatite ultra-long nanowires of the present invention can be prepared by solvothermal method, and can be prepared by referring to literature and patent reports: Zhu Yingjie, Lu Bingqiang, Chen Feng, High flexibility, high temperature and non-combustible hydroxyapatite Paper and its preparation method, patent number ZL201310687363.2; Ying-Ying Jiang, Ying-JieZhu, Feng Chen, Jin Wu, Ceramics International, 41, 6098-6102 (2015); Yong-GangZhang, Ying-Jie Zhu Feng Chen, Jin Wu, Materials Letters, 144, 135-137 (2015). Other suitable preparation methods can also be used, as long as the method can be used to prepare the hydroxyapatite ultra-long nanowires. The diameter of the hydroxyapatite ultra-long nanowires may be 5-100 nm, and the length may be 20-2000 μm.

[0023] The present invention preferably adopts a two-dimensional network structure hydroxyapatite nanowire assembled from hydroxyapatite nanowires wi...

Embodiment 1

[0036] Glass fibers with a length of 3 mm and a diameter of 6 μm are configured into an aqueous suspension with a concentration of 0.5 wt.%, and mixed with an aqueous suspension of hydroxyapatite ultralong nanowires with a concentration of 0.5 wt.%. The weight percentage of the long nanowire is 80wt.%. After slowly stirring for 1min, the slurry is obtained. The compounded slurry is formed by filtration on a Kaiser rapid paper former, and the formed paper is squeezed (the pressure is 5MPa, time is 3 minutes), dried (at a temperature of 95° C. and a time of 3 minutes) to prepare an inorganic fire-resistant paper with a thickness of 190 μm and a tensile strength of 6 MPa. The inorganic fire-resistant paper is cut into a width of 20mm for optical (electrical) cables with flame-retardant fire-resistant heat-insulating tapes;

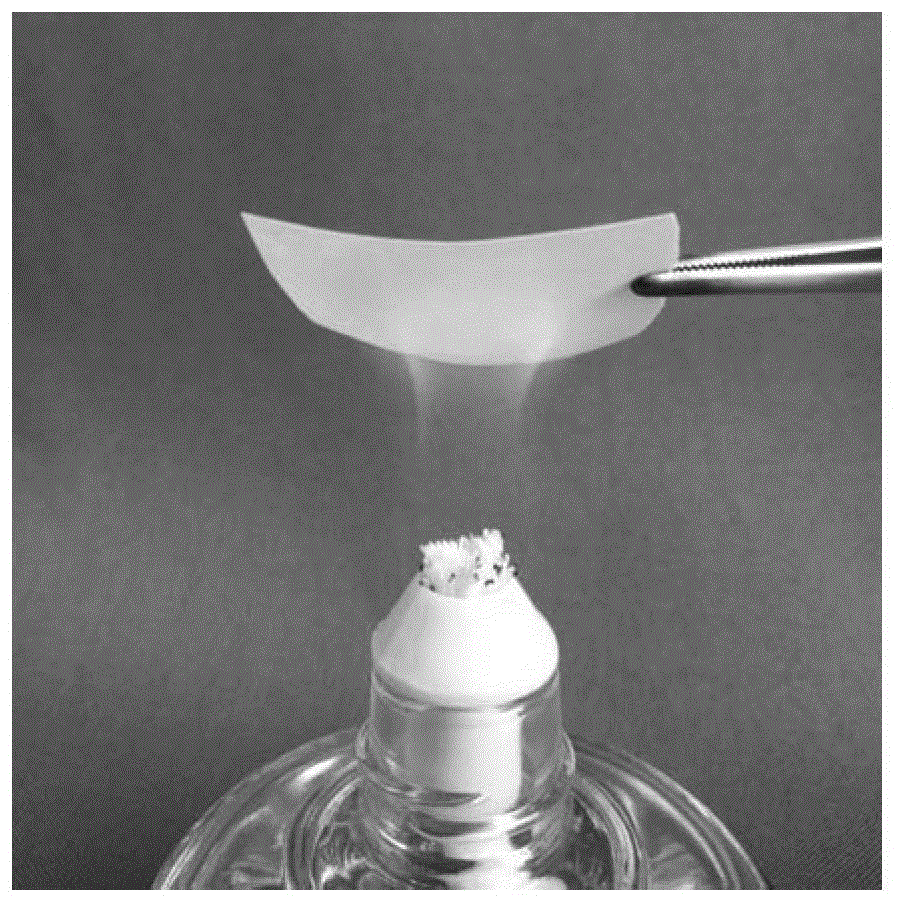

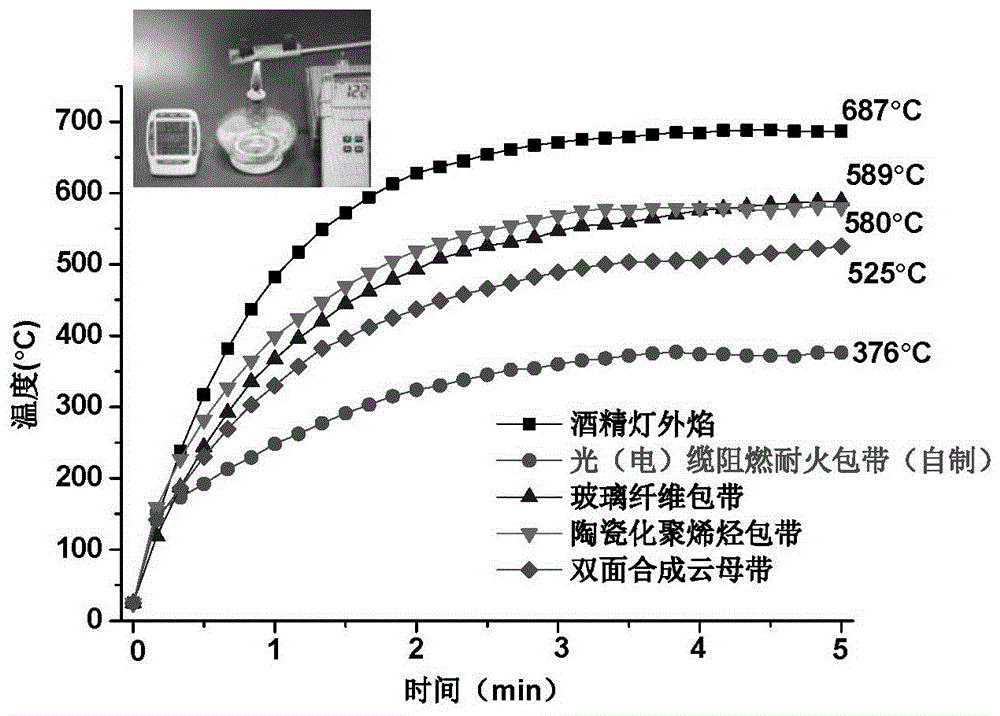

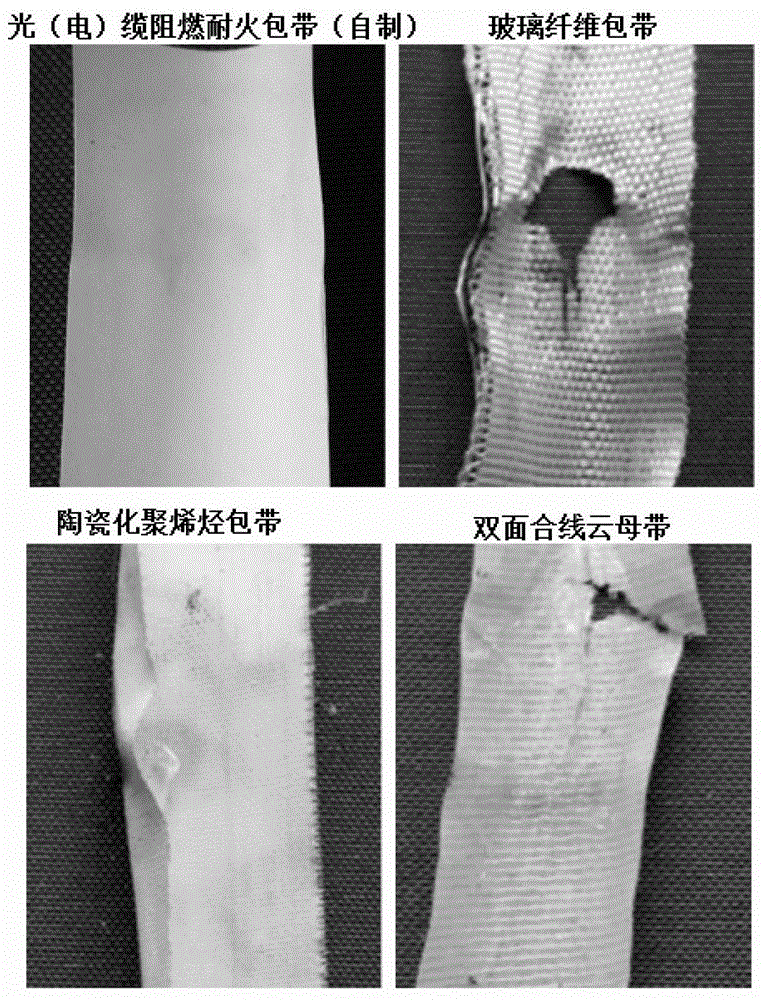

[0037] Wrap the flame-retardant and heat-resistant heat-insulating tape on the thermocouple and burn it on the flame of the alcohol lamp for 5 minutes, the t...

Embodiment 2

[0039] Glass fibers with a length of 6 mm and a diameter of 6 μm are configured into an aqueous suspension with a concentration of 0.2 wt.%, mixed with an aqueous suspension of hydroxyapatite ultralong nanowires with a concentration of 0.5 wt.%, and the ultra-long nanowires of hydroxyapatite The weight percentage of the long nanowire is 60wt.%. After slowly stirring for 1min, the slurry is obtained. The compounded slurry is filtered and formed on a Kaiser rapid paper former, and the formed paper is squeezed (the pressure is 2MPa, time is 8min), dried (temperature is 65°C, time is 30min), and then prepared into an inorganic fire-resistant paper with a thickness of 100 μm and a tensile strength of 5 MPa. The inorganic fire-resistant paper was cut into flame-retardant, fire-resistant and heat-insulating tapes for optical (electrical) cables with a width of 20 mm. Wrap it on a thermocouple and burn it on the flame of an alcohol lamp for 5 minutes, and the temperature of the thermo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com